Allen Bradley 1485 Series DeviceNet Media System

Flat media system (pages 2-19): including KwikLink ™ Lite universal, heavy-duty flat cables and matching connectors, tap cables, etc;

Circular media system (pages 20-34): including thick and thin circular cables, sockets, terminal boxes, T-shaped interfaces, etc;

Auxiliary power circular dielectric system (pages 35-39): including auxiliary power cables, through board connectors, short-circuit plugs, etc.

Allen Bradley 1485 Series DeviceNet Media System

Core Framework and Classification of Documents

The document is divided into three major modules based on media type, covering multiple bullet type components such as 1485A/C/F/G/K/P/R/T. Each module is subdivided into "cable connector auxiliary components" to form a complete DeviceNet network media solution:

Flat media system (pages 2-19): including KwikLink ™ Lite universal, heavy-duty flat cables and matching connectors, tap cables, etc;

Circular media system (pages 20-34): including thick and thin circular cables, sockets, terminal boxes, T-shaped interfaces, etc;

Auxiliary power circular dielectric system (pages 35-39): including auxiliary power cables, through board connectors, short-circuit plugs, etc.

Core component technical specifications

(1) KwikLink Flat Media System ™ Series)

Flat Cable

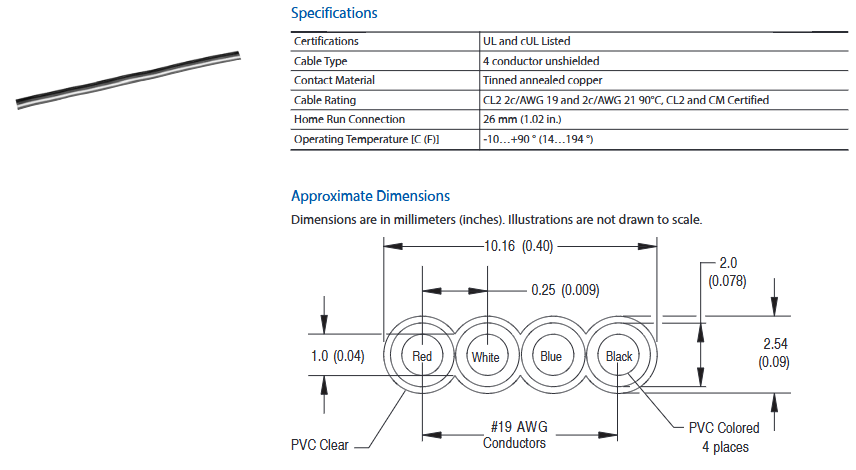

General/Heavy duty commonality: 4-core unshielded design, conductor material is tinned annealed copper, UL/CSA certification, working temperature -25~+75 ° C (heavy duty)/-10~+90 ° C (Lite type), voltage level 600V (auxiliary power type)/300V (signal type);

Differences: Heavy duty cables are UV resistant and oil resistant, suitable for outdoor/harsh environments (such as UL TC 600V 75 ° C sun resistance); Lite type is CL2/CM certified and suitable for indoor wiring (such as 19/21 AWG conductors).

Typical dimensions: Heavy duty cable width 19.3mm (0.76in), Lite type width 10.16mm (0.40in), conductor insulation layer made of colored PVC (red/white/blue/black).

Flat media connector

Types: Trunk connectors, tap connectors, flat circular converters, IDC (Insulated Displacement Connectors), etc;

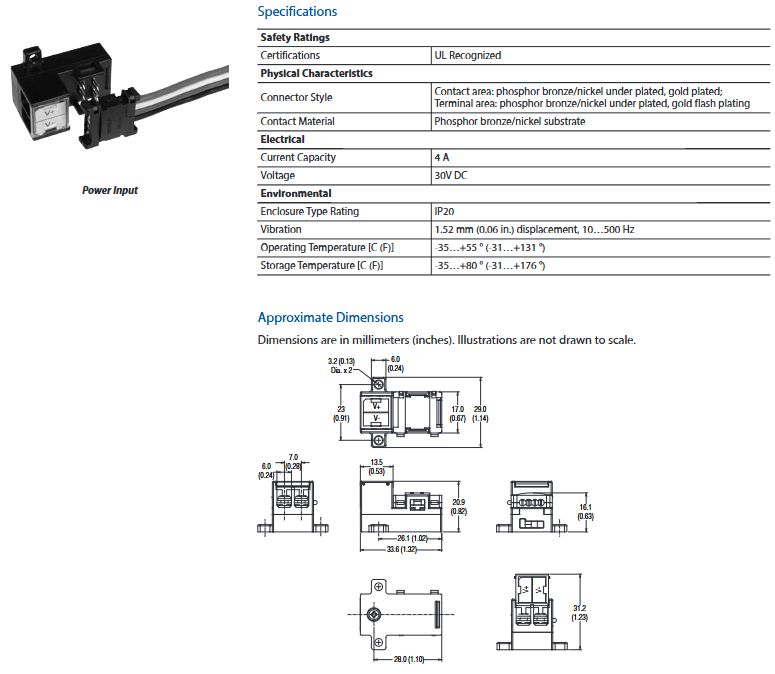

Core parameters: Contact material is phosphor bronze plated with nickel/gold, current capacity is 4A, voltage is 30V DC (Lite type)/250V (heavy-duty), protection level is IP20 (Lite type)/IP67 (heavy-duty, NEMA 6P/131200 psi flushing);

Environmental adaptability: Operating temperature -35~+55 ° C (Lite type)/-40~+100 ° C (heavy-duty), anti vibration (1.52mm displacement, 10~500Hz).

Auxiliary components

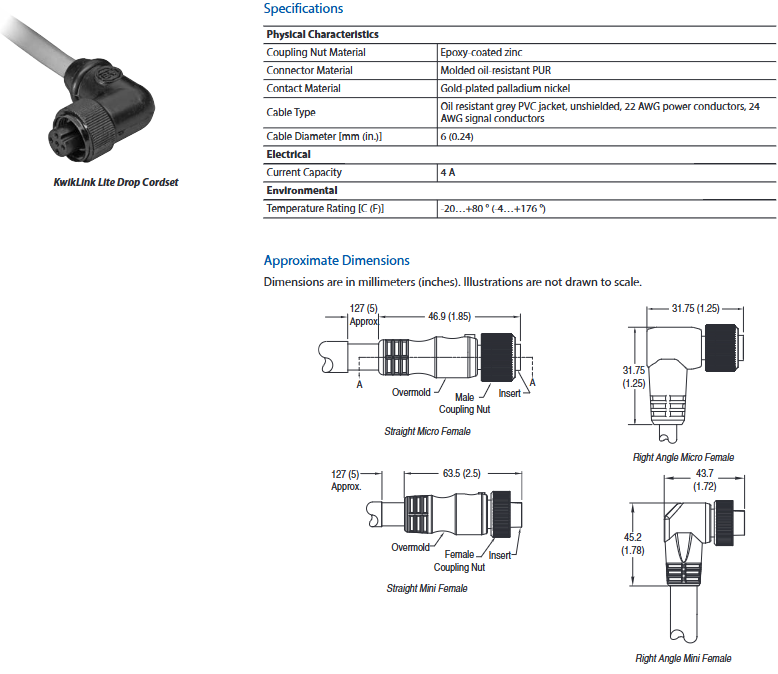

Tap changer cable: Oil resistant PUR shell, 22 AWG power wire+24 AWG signal wire, diameter 6mm, operating temperature -20~+80 ° C;

Terminal block IDC: gold-plated contacts, supporting 4A current, suitable for connecting flat cables to equipment terminals;

Splicing kit: Valox material shell, used for extending flat cable trunks, with a protection level of IP60 (unsealed)/IP67 (sealed).

(2) Circular medium system

round cable

Classification: Classified by thickness as "thick trunk cable" (12.2mm diameter, 15 AWG+18 AWG conductor pair+ground wire) and "thin trunk cable" (6.9mm diameter, 22 AWG+24 AWG conductor pair+ground wire);

Certification and level: UL Type PLTC/CM/TC-ER, CSA AWM I/II, oil resistant, UV resistant (thick cable), working temperature -20~+70 ° C;

Current capacity: Thick cable 8A (NEC 4A), thin cable 3A, voltage 300V (thick)/250V (thin).

Circular media connectors and interfaces

Receptacle: Mini/Micro, contact gold-plated brass, protection level IP67 (NEMA 6P), operating temperature -40~+80 ° C;

Terminal Chambers: Nylon shell, supports M12 threads, compatible with Mini/Micro connectors, resistant to impact (5g) and vibration (30-120Hz);

T-port: Made of PUR/TPE material, Mini type supports 8A current, Micro type supports 4A current, protection level IP67, suitable for branch wiring;

Bulkhead Pass thru: Nickel plated brass shell, Mini type 600V/8A, Micro type 250V/4A, used for cabinet through board sealing.

Network extension component

DeviceBox/DevicePort: 2/4/8 ports, made of black chemical resistant polymer material, with a protection level of IP67, supporting coarse/fine cable access, suitable for centralized wiring of multiple devices;

Terminator: Matching Mini/Micro connectors, 250V/4~8A, used for impedance matching of bus terminals;

Y-shaped adapter: made of nylon material, IP20 protection, 24V/8A, used for branch expansion of open wiring.

(3) Auxiliary power circular dielectric system

Specially designed to provide auxiliary power transmission for DeviceNet devices, the core components include:

Auxiliary power cable

Specification: 16 AWG (600V)/18/22 AWG (300V), yellow oil resistant PVC shell, UL STOOW/AWM certification, operating temperature -20~+105 ° C;

Current capacity: 16 AWG up to 10A, 18/22 AWG up to 4A, suitable for powering high-power equipment.

Specialized connector

Board connector: Mini type 600V/8A, protection level IP67, suitable for cabinet board insertion of auxiliary power cables;

Power T-type interface: 4-core Mini connector, 250V/4A, used for branch power supply of power supply main line;

Short circuit plug: made of red Santoprene material, 600V/10A, used for safe short circuit in case of equipment power failure.

Wiring specifications

4-core pin definitions: 1 (black, V -), 2 (white/blue, signal), 3 (red/brown, V+), 4 (green, signal);

Auxiliary power and signal cables need to be wired separately to avoid interference.

Common technical requirements and application scenarios

Certification and Compliance

All components are UL/CSA certified and partially comply with EN standards (such as IP67 protection), meeting industrial environmental safety requirements (such as NEC, IEC 529).

environmental adaptability

Temperature: Most components operate at temperatures ranging from -20 ° C to+70 ° C, while heavy-duty components can operate at temperatures as low as -40 ° C and as high as+105 ° C;

Protection: Outdoor/harsh environment components (such as heavy-duty flat cables, IP67 connectors) support oil resistance, UV resistance, and high-pressure flushing (1200 psi);

Mechanical performance: anti vibration (displacement of 10-500Hz), anti impact (5g), suitable for dynamic scenarios such as machine tools and automated production lines.

Wiring and installation

Conductor connection: IDC (Insulation Displacement Connection) is preferred to reduce wiring errors;

Shielding and grounding: Circular cables contain grounding wires, while flat cables are grounded at one end through cabinet grounding clamps to avoid electromagnetic interference;

Bending radius: All cables must meet a bending radius of "10 times the diameter" to prevent conductor breakage.

Core applications and selection suggestions

Application scenarios

Indoor automation equipment (such as PLC, sensors): Choose KwikLink ™ Lite flat media or thin circular media;

Outdoor/harsh environments (such as automotive production lines, food processing): Choose heavy-duty flat media or coarse circular media (IP67 protection, oil resistance);

High power equipment (such as servo motors): equipped with auxiliary power supply circular dielectric, powered by 16 AWG cable.

Key parameters for selection

Current: Select cables based on device power (such as thin cables for 3A and below, and thick cables for 8A and above);

Protection: Choose IP67 components for humid/dusty environments, and IP20/IP60 for dry environments;

Temperature: For low-temperature environments (such as cold storage), select -40 ° C low temperature resistant components, and for high-temperature environments (such as metallurgy), select+105 ° C high temperature resistant cables.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands