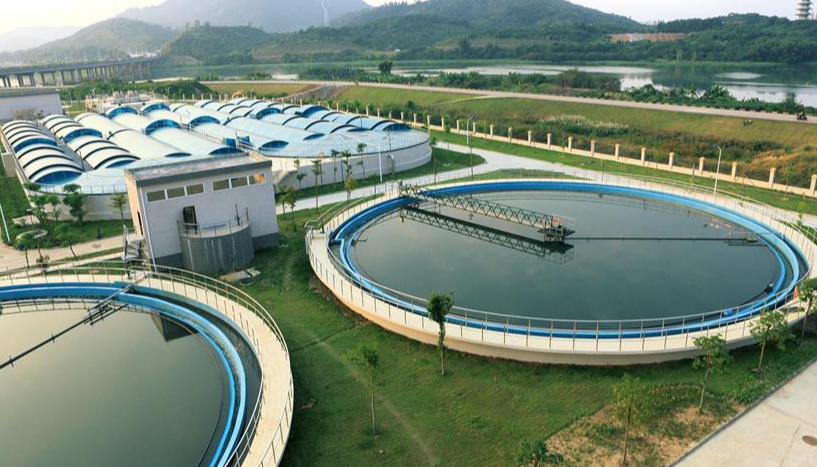

Intelligent integrated domestic sewage treatment system

The traditional sewage treatment method is difficult to achieve the desired effect, therefore, at present, we can use intelligent control technology for sewage treatment, which can effectively deal with various situations in the sewage treatment process, and monitor it, to a certain extent, can improve the stability of the sewage treatment operation system, but also promote the reliability of the treatment results.

The basic situation of intelligent control system

At this stage, according to the current application of intelligent control system in sewage treatment, we mainly simulate human brain thinking based on computer technology, and integrate artificial intelligence technology to carry out scientific and effective monitoring and testing of the whole process of sewage treatment operation system, and realize the intelligence of the whole process of operation system.

At the same time, in the process of sewage biological intelligent control system, we mainly choose hardware and software systems, which hardware systems mainly include: sensors, various detection equipment, as well as intelligent controllers and communication interfaces; The software system is mainly for the learning of the cognitive intelligent control system, as well as the processing of information perception and the mastery of the database.

With the continuous development of social economy in our country, the sewage treatment standards have been put forward with the highest requirements. Only by removing the nitrogen compounds and organic compounds completely can we purify the sewage system. Therefore, in the practice process, in order to achieve a way to deal with a variety of undesirable impurities at the same time, we can use intelligent control technology to regulate and control the input or output of the sewage treatment system, as well as the time aspect, and effectively combine the relevant data to control and effectively improve the sewage treatment biology.

(1) The pretreatment of sewage through grid interception is aimed at initially reducing the content of inorganic particulate matter and improving the identity and biodegradability of sewage

(2) Then the water quality and quantity of the regulating tank are adjusted by the lifting pump. The adjusted sewage is converted into nitrogen by anoxic and aerobic A/O biological contact oxidation method, and the organic pollutants ** are converted into nitrogen by the biofilm. At the same time, organic matter and nitrogen are removed by aerobic nitrification and anoxic denitrification processes.

(3) The biochemical tank is equipped with a new type of high-density elastic three-dimensional filler, which has the advantages of high load, simple construction, small volume, stable and reliable operation, convenient management, easy maintenance and replacement;

(4) The effluent from the biochemical tank enters the second sedimentation tank for solid-liquid separation. The second sedimentation tank has the characteristics of good solid-liquid separation effect, saving energy, strong adaptability to impact load and temperature change, and easy construction.

(5) The effluent from the second sedimentation tank will enter the disinfection tank for disinfection treatment, and after disinfection treatment, all indicators of the sewage can be fully reached after treatment.

Intelligent integrated domestic sewage treatment system

The domestic sewage treatment equipment we use is relatively small, because it is installed in the ground, so it can save land, unlike the previous kind of need to build houses, this is not needed, and the construction is easier and the installation is flexible. Therefore, the current domestic sewage treatment equipment covers a small area and the equipment is standardized. Even when it's used, it's easy. It can be used in rural pollution sources. Life expectancy is generally relatively long, and the normal situation can reach more than 15 years. At the same time, it also has the advantage of reducing sludge production. This equipment also has automatic intelligence system and alarm prediction system. There is no need for special protective devices in the process of use. Sewage treatment equipment in use is the need for electricity, this time to pay attention to the occurrence of leakage, this is to everyone often to check, at least once a month, if there is a failure to quickly change. If it is said that the fuse is blown, it is necessary to identify the elements and eliminate the fault before resuming the power supply. In addition, if there are some open or cracked live joints exposed to the outside, at this time we must quickly find insulation wrap, and placed in the place where people are not easy to touch, otherwise there will be other unexpected things to happen. This is also an important point to remember. In addition to the above in the use of the process to pay attention to accidents, domestic sewage treatment equipment in use, do not pull the wire, once found wires or plugs, sockets and other damage, it is necessary to replace. Do not use a steel tape measure or a steel tape measure around the sewage treatment equipment when there is a point, and if someone is maintaining it, know the operator immediately.

Domestic sewage treatment equipment is inseparable from life. In some buildings and public buildings, some waste water is often discharged. If not treated, the waste water will easily decompose and produce foul odor. Some of the bacteria and pathogens in it will multiply in large numbers, and over time it will lead to the spread of infectious diseases. Therefore, domestic sewage must be treated, otherwise the harm is great, and it will directly affect the hardness of groundwater. This may not be known to most friends, once the hardness of water becomes difficult to drink, the impact on our health is relatively large, and even affect industrial production.

In terms of the composition of domestic sewage, rural domestic sewage and urban domestic sewage are similar, and domestic sewage mainly comes from toilets, washings, kitchens, etc., which belong to low concentration sewage with good biochemical properties. The urban population is huge, so the amount of domestic sewage produced every day is very huge, and it is centrally collected to the sewage plant for treatment through the unified sewage treatment network. Due to the sparse population in rural areas, the generation and distribution of sewage is extremely dispersed, only a few areas are suitable for the establishment of sewage treatment networks or small sewage treatment plants, and most rural sewage is directly discharged or on-site treatment.

The rural sewage treatment project to copy the sewage treatment plant model often ends in failure. The process of sewage treatment plant is mostly to deal with large-scale domestic sewage. The amount of domestic sewage in rural areas is small and the water quality fluctuates greatly, so it is necessary to adopt decentralized sewage treatment technology according to local conditions, or make domestic sewage realize resource utilization.

At present, in the construction of sewage treatment projects in rural China, more integrated sewage treatment equipment is used, such equipment basically realizes standardized large-scale production, and has a slight advantage over the construction of sewage treatment plants in terms of capital investment. The integrated sewage treatment equipment is equipped with an intelligent system, which can carry out remote monitoring, instant detection and early warning of the water quality, flow rate and pressure of the water entering and leaving the sewage treatment process.

1. High degree of automation

Using MBR membrane technology, greatly shorten the process flow, through advanced automatic control technology, make the equipment highly integrated and intelligent.

2. Good effluent water quality

MBR integrated sewage treatment equipment adopts membrane technology, the effluent quality is superior to the traditional sewage treatment equipment in all aspects, and the effluent can be reused as miscellaneous water.

3. Small footprint

Due to the efficient separation effect of the membrane, there is no need to set up precipitation, filtration and other solid-liquid separation equipment, and the concentration of suspended matter in the effluent is much lower than that of the traditional solid-liquid separation equipment, so that the whole system process is simple, easy to integrate, and the system covers a small area.

4, save operating costs

MBR membrane bioreactor can filter out bacteria, viruses and other harmful substances, can reduce the disinfection device and daily dosage, making management and operation more convenient.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands