Foxboro I/A Series Compact 200 16 Slot Horizontal Substrate (31H2C480B4)

Module support: Provides 16 standard slots for installing Compact 200 series I/O modules (such as analog input/output modules, digital modules, HART communication modules, etc., as previously summarized for FBM218 module);

Signal and power distribution: The internal bus is used to achieve signal interaction between the substrate and various I/O modules, power supply, and communication connection between the modules and the higher-level controller;

Redundancy support: compatible with module level redundancy configurations (such as dual module redundancy), providing hardware foundation for high reliability of I/O subsystems;

Environmental adaptation: Adapt to harsh industrial environments such as dust, vibration, and wide temperature ranges to ensure stable operation of the I/O subsystem.

Foxboro I/A Series Compact 200 16 Slot Horizontal Substrate (31H2C480B4)

Core positioning and subsystem roles

The Compact 200 16 slot horizontal substrate is the "hardware backbone" of the Foxboro I/A Series Compact 200 I/O subsystem, with core functions including:

Module support: Provides 16 standard slots for installing Compact 200 series I/O modules (such as analog input/output modules, digital modules, HART communication modules, etc., as previously summarized for FBM218 module);

Signal and power distribution: The internal bus is used to achieve signal interaction between the substrate and various I/O modules, power supply, and communication connection between the modules and the higher-level controller;

Redundancy support: compatible with module level redundancy configurations (such as dual module redundancy), providing hardware foundation for high reliability of I/O subsystems;

Environmental adaptation: Adapt to harsh industrial environments such as dust, vibration, and wide temperature ranges to ensure stable operation of the I/O subsystem.

Structural design and installation characteristics

(1) Physical Structure and Dimensions

Exterior design: Adopting a horizontal layout, the overall structure is made of metal material frame (balancing strength and electromagnetic shielding), with slot markings (1-16) on the surface for easy module positioning and installation;

Key dimensions (refer to Compact 200 series standards):

Length: Approximately 483mm (19 inches, compatible with standard 19 inch cabinet installation);

Height: Approximately 130mm (5.12 inches);

Depth: Approximately 150mm (5.9 inches, including protruding connector);

Weight: Approximately 1.8kg (excluding modules), lightweight design facilitates cabinet assembly.

(2) Installation method and compatibility

Cabinet installation:

Support installation of 19 inch standard industrial cabinets, requiring a dedicated installation bracket (optional accessory), with a reserved installation depth of ≥ 200mm (including module insertion and removal space);

Compatible with "horizontal installation" (default), the installation angle can be adjusted through the adapter (please refer to the system installation guide);

DIN rail installation:

Supports installation with 35mm standard DIN rail (EN 60715 specification), which needs to be fixed with rail buckles, suitable for on-site scenarios without 19 inch cabinets (such as small control cabinets);

Module installation requirements:

Slot compatibility: All 16 slots support all I/O modules of the Compact 200 series, with no signal type restrictions (analog, digital, and communication modules can be mixed for installation);

Redundant module layout: If configuring redundant I/O modules (such as dual FBM218), they need to be installed in adjacent slots (such as slots 3 and 4, 5 and 6), and the first redundant module needs to be located in an odd numbered slot to ensure normal redundant communication and power switching functions.

Core functions and technical features

(1) Power distribution and redundancy support

Power input and distribution:

Supports dual 24V DC redundant power input (requires external redundant power module), with an allowable voltage fluctuation range of+5%/-10% (i.e. 21.6V DC -25.2V DC);

Internally integrated power distribution circuit, stably distributing redundant power to 16 slot I/O modules, with a maximum power supply current of ≥ 1A per module (meeting the power consumption requirements of most Compact 200 modules);

Power protection: Built in overcurrent protection (does not affect the power supply of other modules in case of single channel overcurrent), reverse connection protection (prevents the positive and negative poles of the power supply from reversing and damaging the substrate);

Redundant switching capability:

When the main power supply fails, the backup power supply can seamlessly switch within ≤ 10ms, ensuring that the I/O module has no power interruption and guaranteeing continuous acquisition/output of process signals;

Supporting "module level redundancy" power supply collaboration, redundant modules share the substrate power bus to avoid redundancy failure caused by single power supply failure.

(2) Signal bus and communication connection

Internal signal bus:

Integrate the "control signal bus" and "status monitoring bus": The control signal bus is used to transmit real-time data (such as 4-20mA analog and digital switch values) between the I/O module and the higher-level controller; The status monitoring bus is used to upload diagnostic information such as module faults and power status;

Bus speed: Control signal transmission rate ≥ 1Mbps, meeting the real-time requirements of industrial processes (delay ≤ 10ms);

Isolation design: Galvanic isolation (isolation voltage ≥ 500V AC/1 minute) is implemented between the signal bus and the power bus to prevent power interference from affecting signal transmission;

External communication interface:

A dedicated "controller connection port" (usually a multi pin industrial connector) is installed on the back of the substrate, which is connected to Foxboro I/A Series controllers (such as Evo controllers) through dedicated cables to achieve overall linkage between subsystems and control systems;

Support redundant communication links (with the cooperation of the controller). When the main communication link fails, the backup link will automatically switch to ensure that data is not lost.

(3) Fault diagnosis and maintenance convenience

Status indication:

The front of the substrate is equipped with LED indicator lights, including a "power status light" (main/backup power, green constant light indicates normal, red flashing indicates fault), a "bus status light" (yellow constant light indicates normal, off indicates bus interruption), and a "module fault summary light" (red light indicates any slot module fault), which facilitate quick judgment of the system status;

Module hot plug support:

All 16 slots support "hot swappable" (the module itself needs to have a hot swappable design). When replacing the I/O module, there is no need to disconnect the power supply or communication cable of the substrate. Simply unlock the module buckle to plug and unplug, reducing maintenance downtime;

Fault isolation:

A single slot is equipped with an independent fault isolation circuit. When a certain I/O module fails, the substrate automatically cuts off the abnormal signal between the slot and the bus to prevent the fault from spreading to other modules or higher-level controllers.

(4) Environmental protection and durability

Anti pollution capability: meets the G3 level (harsh) environmental requirements of ISA standard S71.04, can withstand industrial dust, oil and gas, corrosive gases (such as hydrogen sulfide), and the substrate surface is coated with anti-corrosion coating (such as epoxy resin) to extend its service life;

Resistance to vibration and impact:

Vibration protection: Within the frequency range of 5-500Hz, it can withstand a sine vibration of 7.5m/S ² (0.75g), meeting the installation requirements near vibration sources such as pumps and compressors;

Impact protection: capable of withstanding a 15g (half sine wave, duration of 11ms) impact, suitable for the impact environment of industrial equipment transportation and on-site installation;

Temperature adaptability: Operating temperature range -20 ° C to+60 ° C, storage temperature range -40 ° C to+85 ° C, suitable for most industrial scenarios (such as chemical workshops, outdoor control cabinets).

Detailed explanation of technical specifications

(1) Electrical specifications

Specification category parameter details

Power input voltage: 24V DC (redundant dual input); Voltage fluctuation range:+5%/-10%; Maximum input current: 10A (total power consumption varies with the number of modules)

Maximum output current of a single slot for power distribution: 1A; power bus voltage drop: ≤ 0.5V (at full load)

Signal bus type: differential signal bus; Transmission rate: ≥ 1Mbps; Signal delay: ≤ 10ms

Isolation performance power signal isolation: 500V AC/1 minute; Slot isolation: 600V AC/1 minute

Overcurrent protection single slot overcurrent protection threshold: 1.5A (self resetting, automatically restoring power supply after troubleshooting)

(2) Mechanical and Environmental Specifications

Specification category parameter details

Dimensions and Length: 483mm (19 inches); Height: 130mm; Depth: 150mm; Weight: Approximately 1.8kg (excluding modules)

Installation method: 19 inch cabinet installation (requires bracket), 35mm DIN rail installation (EN 60715)

Working temperature -20 ° C to+60 ° C (non condensing)

Storage temperature -40 ° C to+85 ° C (non condensing)

Working humidity 5% -95% RH (non condensing, temperature ≤ 40 ° C)

Anti vibration of 5-500Hz, 7.5m/S ² (0.75g), in compliance with IEC 60068-2-6 standard

15g shock resistance (half sine wave, 11ms), in compliance with IEC 60068-2-27 standard

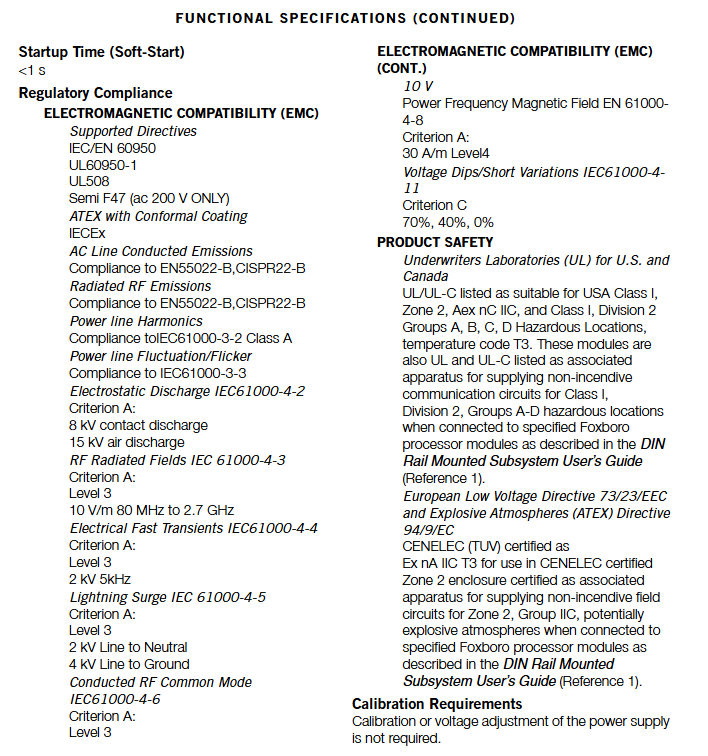

(3) Compliance certification

Electromagnetic compatibility (EMC): complies with the EU EMC Directive (2014/30/EU), meets the Class A emission requirements (industrial environment electromagnetic radiation control) and industrial immunity level (anti-static discharge, radio frequency interference, electrical fast transient pulse group) of EN 61326-1:2013 standard;

Security certification:

UL/UL-C certification: suitable for hazardous environments with Class I A-D groups, Zone 2, T4 temperature codes (requires Foxboro I/A Series certified controllers and modules);

ATEX certification: Ex nA IIC T4 Ga, suitable for Zone 2 hazardous environments (such as chemical explosion risk areas);

IECEx certification: compliant with IEC 60079-15 standard, supporting global hazardous area applications;

Environmental compliance: Compliant with the EU RoHS Directive (2011/65/EU), restricting the use of harmful substances such as lead, mercury, cadmium, etc;

Marine certification: Some models have been certified by American Bureau of Shipping (ABS) and Bureau Veritas, meeting the environmental and safety requirements of marine environments such as ship power systems and offshore oil platforms.

Supporting components and reference documents

(1) Key supporting components

Component type, model/specification, core function

The redundant power module is compatible with the Compact 200 series (such as relevant RH models) to provide dual 24V DC redundant power input for the substrate, ensuring power reliability

Installation bracket 19 inch cabinet specific bracket is used for the fixed installation of substrates inside the 19 inch cabinet, ensuring installation stability

Controller connection cable dedicated multi-core industrial cable connection substrate and Foxboro I/A Series controller to achieve data and control signal transmission

Terminal components (TA) such as RH926SP (previously compatible with FBM218) are connected to the I/O modules on the substrate through cables, providing wiring interfaces for field devices

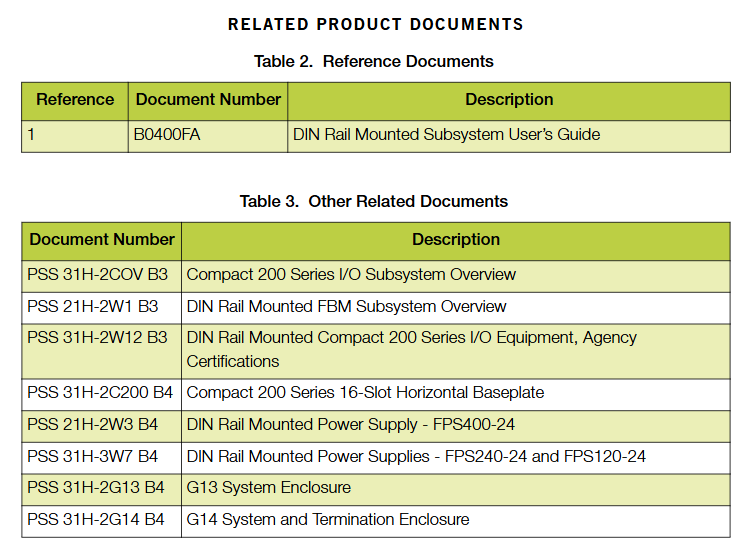

(2) Reference Documents

Document Number/Reference Number Document Name Core Content

31H2C480B4 Compact 200 Series 16 Slot Horizontal Substrate Product Specification Table Detailed Technical Parameters, Installation Dimensions, Electrical Characteristics, Certification Information of Substrate

Overview of PSS 31H-2COV Compact 200 Series I/O Subsystem: Overall Architecture of Subsystem, Matching Rules of Substrate and Module, Redundancy Configuration Scheme

B0400FA standard and Compact 200 series subsystem user guide: substrate installation steps, module insertion and removal operations, fault diagnosis process, daily maintenance precautions

PSS 31H-2C218 FBM218 module product specification sheet (previously summarized document) Detailed specifications of the substrate compatibility module to assist in confirming the compatibility between the module and the substrate

Differences from other Compact 200 substrates (supplementary explanation)

The Compact 200 series substrate includes multiple specifications (such as slot number and installation method), and the core differences between the 16 slot horizontal substrate (related to 31H2C480B4) and other models are as follows:

Comparison dimension: 16 slot horizontal substrate (in this document), 8 slot horizontal substrate (in the same series), vertical substrate (in the same series)

16 slots (supporting more modules, suitable for large I/O subsystems) 8 slots (suitable for small and medium-sized subsystems, saving space) 12 slots (vertical layout, suitable for narrow cabinet scenarios)

Installation method: 19 inch cabinet+DIN rail 19 inch cabinet+DIN rail Only DIN rail (vertical installation, saving horizontal space)

Maximum module power consumption supports total power consumption ≤ 16A (calculated based on a single module 1A), supports total power consumption ≤ 8A, supports total power consumption ≤ 12A

Typical Application Scenarios: Centralized I/O Stations in Large Chemical and Power Systems, Distributed I/O Stations in Small and Medium sized Production Lines, and Space Constrained Sites (such as Outdoor Small Control Cabinets)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA