Born to the mine, Huawei makes the construction of smart mines reach the realm of no one

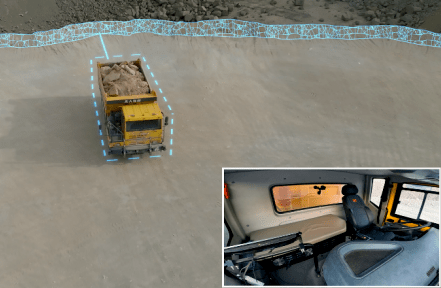

In the spring of 2023, in an open-pit mine in the northwest, 100-ton mining cards are crossing the dust, accurately stepping on the ruts of the road, whistling up. The bright indicator lamp from far to near, gradually set off the huge figure, like the light coming in the dark messenger. This is an unmanned mining card. In the complex mining scene, relying on the collaborative control of "vehicle-road-cloud", it smoothly turns a U-shaped curve, avoids obstacles on the road, and runs at full speed on the mining ramp at a rated speed of 40Km, achieving centimeter-level accurate alignment and 7×24 hours all-weather operation. Behind such a scenario, it shows a complete set of mine driverless solutions created by Huawei based on the vehicle gauge level self-developed hardware and full-stack software algorithm.

On March 30, at the 3rd TIAA Conference on Integrated Application Results of Automatic Driving and Safety Production in the Mining Field held in Changsha, Hunan Province, Huawei officially launched the driverless solution for open pit mines. Just like the powerful mining car that passes through the dust, Huawei's solution breaks through the fog of the unmanned mining industry and jointly promotes the dust settlement of commercialization!

1 Enter the mine driverless Huawei why?

Safety in production is always the top priority of mines. Although the "2022 Annual Report on the Development of the coal Industry" released by the China National Coal Industry Association shows that the mortality rate of coal mines per million tons has been reduced from 0.374 to 0.054 in the past 10 years. However, the recently widely concerned open-pit accident has profoundly reminded us that even the safe production of open-pit mines can never be taken lightly.

In creating safe and efficient production mines, the state has always attached great importance to scientific and technological innovation. With the guidance of the eight ministries and commissions on Accelerating the Intelligent Development of Coal Mines in 2020, the intelligent construction of open-pit mines has developed rapidly in recent years. Even in the "Opinions of the People's Government of the Inner Mongolia Autonomous Region on Promoting the high-end, intelligent and green development of the manufacturing industry", it is clear that the quantitative target of "smart mine (driverless/vehicle) will increase from 110 units in 2021 to 1,200 units in 2025".

In this wave of the industry, Huawei has deeply empowered the development of the industry with the strong capability of ICT infrastructure and the strategy of legionalization. In the field of commercial vehicles, it has laid out hardware such as improved vehicle gauge chip, MDC computing platform, and low-cost Lidar, and Huawei Cloud and AI large models are unique at the software level. Obviously, the output of Huawei's mine unmanned driving program is a must.

2 What are Huawei's advantages in promoting technological progress in the industry?

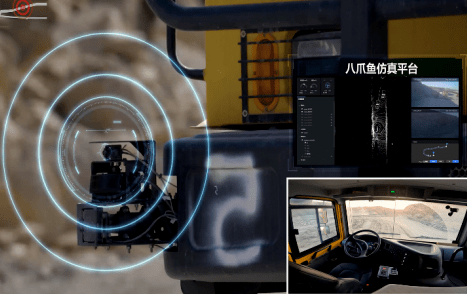

First, Huawei builds "smart cars." Huawei's technical capabilities cover almost the full capability set of chips, computing platforms, sensors, and algorithms. Relying on Huawei Kirin vehicle gauge chip and MDC intelligent driving computing platform, the vehicle has a brain, ensuring the high safety and reliability of autonomous decision-making of the vehicle. In terms of perception system, the vehicle is equipped with a compound eye matrix such as Lidar, millimeter-wave radar, and camera, and the continuous algorithm iteration of multi-device fusion perception makes the vehicle more and more intelligent. Not only that, Huawei has specially developed automatic driving algorithms for the optimization of six scenarios: dust, rock fall, obstacle, bumpy road, active vibration reduction and shock prevention, and excavator/retaining wall positioning, so that the vehicle can still achieve accurate, efficient and safe operation under comprehensive conditions.

Second, Huawei builds a "smart road." 5G+V2X of the roadside unit is clearly Huawei's traditional strength. Through the construction of 5G network, its low-delay and high-reliability characteristics can ensure the control experience of remote drivers to take over the vehicle, and restore the scene and feedback the control instructions in real time. At the same time, the characteristics of large bandwidth can fully meet the synchronous upload of multi-channel high-definition video and sensor data, opening up channels for cloud planning and vehicle execution. In terms of V2X functions, the optimal decision control of the global system can be achieved by providing over-the-horizon and multi-dimensional holographic sensing capabilities.

Third, Huawei has also built a "powerful cloud". Through the powerful algorithm and computing power support of the cloud, the mining car can be refined path planning and speed guidance, and the overall integration of mining equipment resources, to achieve macro scheduling and improve work efficiency. The two pillars supporting the cloud brain are simulation and high-precision maps. The autonomous driving cloud service provided by Huawei includes a large number of scene simulations, especially the mining and simulation of complex and difficult cases, which enables the autonomous driving algorithm in mining areas to take simulation as a priori and self-test based on actual conditions, and constantly iterate and upgrade to effectively cope with various harsh working conditions. The ability to support the combination of virtual and real simulation and measurement naturally depends on its high-precision map cloud service with Class-A qualification. Through efficient drawing construction and minute-level dynamic refreshing of the mining loading area and the soil discharge area, the mining car can achieve centimeter-level accurate positioning and safe distance accurate parking, which greatly improves the collaborative operation ability of the vehicle shovel.

Hidden skills may be the only way to do deep industry

In addition to the vehicle-road-cloud architecture, we believe that its ability to complete the training of the perceptual model based on a small sample amount of data will be the key to its ability to understand the scene and continue to play the technology.

Huawei's sensing algorithm has strong adaptability to the environment, improving the reliability and versatility of technology in different operating environments. This greatly reduces the requirements for data collection and the difficulty of algorithm training, improves the ability of accurate target detection in a sand and dust environment, and provides protection for safe driving with long-distance vehicle identification, retaining wall boundary and highly accurate identification, ground relief detection, soil gravel or small stone detection, etc.

Having this ability actually means that the landing flexibility of Huawei's solution is higher, that is to say, it has the ability of commercial replication.

Open cooperation, build a full stack ecology on top of full stack capability

There is no denying that unmanned vehicles need to become a part of smart mines and serve the overall construction of smart mines. In addition to the capability of driverless "car-road-cloud" scenarios in mines, Huawei also has full-stack technical capabilities for smart mine integration such as mining Hong (mine Internet platform), smart park, digital cloud platform base, 5G, Pangu model (AI), etc., which can consider the overall development needs of mines and pull through various informatization automation systems in mines. Avoid duplicative digital building investments.

However, this does not mean that Huawei should do all the work. In fact, full-stack capability is precisely for full-stack ecological cooperation. Attaches great importance to industry cooperation and co-construction. Not only that, in the practice of landing in the field of mine autonomous driving, Huawei has also actively opened its own capabilities to industry companies. At present, partners such as Easy Control Intelligent Driving, Hibo Intelligent Energy, Xidi Intelligent Driving, Huituo, Tage Zhixing, and Bolai Technology have applied Huawei's hardware products and customized technologies.

3 How is the construction of open-pit intelligent mine Huawei?

In October 2021, Huawei began to deploy the mine unmanned deployment system in Xingsheng open-pit Coal Mine in Xinjiang (with a production capacity of 23 million tons/year). In the process of promoting the project, Huawei deeply integrated artificial intelligence, cloud computing, vehicle networking, intelligent driving, high-precision map and other technologies with modern coal mining, realized the continuous operation of the full process of mining, transportation and drainage of automated mining trucks in open pit mines, and gradually promoted the commercial deployment of more than 70 vehicles within three years.

Efficient and safe, mine driverless equal manual operation

In the test of the Jiangna project, through a one-month continuous test of the actual production environment, the operational efficiency of "unmanned" and "manned" was compared. The results show that the actual operation time of unmanned driving can reach 22 hours per day, and the continuous operation of the whole process without safety personnel, and its comprehensive efficiency has reached more than 90% of that of manual driving, and the overall effect is almost comparable to that of manual driving. In the near future, with the improvement of system performance, more data accumulation and more mature algorithm training will push unmanned driving gradually beyond the human level.

In addition, in terms of safety, mine driverless can provide higher safety and reliability. In the process of solving multi-vehicle right-of-way conflicts, Huawei Vehicle Cloud collaborative solution can avoid path conflicts and multi-vehicle deadlocks at the planning level based on the "God perspective", and realize global situation awareness through roadside facilities, improve blind area obstacle detection capabilities, and greatly improve vehicle safety and reliability.

Build the "strongest brain" in the cloud, and see real efforts in details

The engineering process of the open-pit mine scene is intelligent, and the most tested is not the standardized process, but the conversion of the joint junction point of mining, transportation and drainage. The adaptability of Huawei's mine driverless solution is well reflected in the details of these scenarios.

The first is the ability to perceive the unique scene of the mine. Based on the powerful perception model, the car can accurately detect small targets such as falling rocks in the dust environment; Through precise semantic segmentation, the car can distinguish the boundary between the mine retaining wall and the ground well, as well as the irregular and dynamically changing production surface. Even for the objects that need to be identified, such as mine sprinklers and refueling trucks with few samples, it can ensure that the trained model has a good generalization ability.

The second is the minute level dynamic update of the high-precision map with the change of the operation area. The cloud can be crowdsourced based on the perception data of the vehicle end, and automatically update the high-precision business map along with the work point and the soil discharge line to ensure the accurate alignment of the collection area and the soil discharge area. The highly refined map of the mine road can also follow the advance and change of the operating point, and automatically update when a set distance threshold is reached.

Dynamic update of high-precision road map in mining area

The third is independent planning to achieve the optimal operation strategy. This is most intuitively reflected in the dump. Based on the dynamic change of the retaining wall edge of the discharge line perceived by the end of the vehicle, the cloud can automatically calculate the discharge level, take into account the queuing strategy, road slope and other factors, and ensure the balanced distribution, so as to support the balanced discharge and special-shaped dump operation.

Cloud discharge point planning view (support balanced discharge and irregular dump)

4 Aiming at the future mine Where is Huawei going?

Full stack enablement is All In

From the first day of entering the industry, Huawei never seems to take the industry scene landing lightly because of the advantages of full stack capability.

In April 2021, Huawei officially established the Coal Mining Army, which invested more than 200 people to form a combat phalanx. Among them, in the smart coal mine joint innovation project team established with Guoneng Shendong, Huawei has more than 70 permanent residents. In June 2022, Huawei also landed the global headquarters of the Coal Mining Corps in Shanxi, a large coal-producing province, which shows that it has given a high degree of strategic positioning to the mining industry in the group floor. Today, Huawei officially entered the field of driverless mining, but also based on the technology accumulation of its intelligent car solution 8,000 people, ICT technology and passenger car mature technology to the open pit mining.

This kind of huge investment fully rooted In the industry has to be said to be an All In attitude.

The whole chain of cooperation, one joy is not as happy as all joy

In 2022, Huawei invested 161.5 billion yuan in research and development, with a R&D expense rate of 25.1%. In the past decade, Huawei has invested more than 977.3 billion yuan in research and development. With such investment in research and development, Huawei hopes to drive the overall progress of the industrial technology ecosystem.

As a platform-based enterprise, Huawei has always embraced industry cooperation and promoted industry maturity. Going forward, Huawei will work together with industry customers and partners. Promote the continuous improvement of industrial policies such as the graded application of unmanned mining technology; Participate in the development of various industry standards at all levels, including TIAA standards; Open their own capabilities and industry cooperation, as a booster and all parties to promote the maturity of the industry; At the same time, strengthen cooperation with Oems, operation and maintenance operation partners, scientific research institutes and other aspects to promote the mature and steady development of the industry.

Put all your heart into it, and there will be a return

After the mining field in recent years and industry-leading demonstrations, Huawei has promoted the implementation of many projects across the country. These projects are not only the embodiment of its technical capabilities, but also reflect its multi-point joint, regional coordination of technical service support capabilities. If the mine driverless solution based on the cargo-level self-developed hardware and full-stack software algorithm is the front of Huawei's business card in open pit mining, then the back of the business card must be the strong talent guarantee and technical service capabilities accumulated in the process of promoting the national project.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands