Lennox ZHA series heat pump complete set (507257-01b)

Electrical safety: power-off operation is a prerequisite - the power supply of the unit must be turned off during any maintenance to avoid the risk of electric shock or explosion; Before powering on, it is necessary to confirm that the voltage meets the range indicated on the nameplate, and the three-phase power supply must ensure phase balance (especially for models with frequency converters).

Air duct requirements: Outdoor air ducts, joints, and roof/wall openings need to be insulated and waterproofed (using waterproof boards and sealant); Air ducts passing through non air conditioned areas must be insulated; Drilling holes in the base of the unit is prohibited in the application of down air supply to prevent roof leakage.

5. Electrical connection (including special model requirements)

Power wiring:

The 230/460/575V models are factory pre wired, and for 208V power supply, all pink (230V) wires of the control power transformers need to be disconnected, reconnected, and the exposed 230V wire ends wrapped;

The power cord needs to be introduced from the bottom entry area and connected to the L1, L2, and L3 terminals of TB13 in the control box. If there is an S48 isolation switch (pre installed in the factory), it needs to be connected according to the wiring diagram.

Three phase voltage balance (with frequency converter model): The frequency converter relies on a balanced three-phase power supply. If the power supply is unbalanced, a higher current level frequency converter needs to be replaced (refer to Table 1:5HP → 7.5HP → 10HP gradually upgraded), otherwise it will reduce the reliability of electrical components.

Thermostat installation:

Location: Vertically installed on a 2 × 4 inch junction box or non-conductive surface, with a height of approximately 5 feet (1524 millimeters), avoiding areas such as air vents, direct sunlight, and electrical radiation;

Wiring: Use 18AWG wire, and non high voltage rated thermoelectric wires should be kept away from the power line and secured with a wire tie in the lower left corner of the control area.

Run debugging and parameter setting

1. Pre startup inspection (mandatory steps)

Confirm that the installation complies with the instructions and local regulations, and that all electrical wiring (factory+on-site) is not loose;

Check that there is no friction in the refrigerant pipeline (avoid contact with the cabinet or other pipelines);

Confirm that the power supply voltage is within the range indicated on the nameplate. If it does not meet the requirements, contact the power company for adjustment;

Install the filter element and ensure that the thermostat has no heating, cooling, or fan requirements before powering on.

2. Fan operation and adjustment

Phase correction of three-phase compressor: The factory has pre-set the phase (L1 red, L2 yellow, L3 blue), and after starting up, it is necessary to observe the suction and exhaust pressure and the direction of the fan. If there is no pressure difference or the direction is incorrect, the power supply needs to be disconnected and any two on-site connections on the incoming side of K3, TB2 or F4 need to be replaced (it is forbidden to replace the fan contactor or compressor connection).

Fan speed and CFM calculation:

Non variable frequency models: Run the fan when there is no cooling demand, measure the fan shaft speed and the external static pressure (between the supply and return air) of the unit, and refer to the fan data sheet on pages 10-12 to determine the CFM;

Variable frequency model: High voltage switches S4 and S7 need to be disconnected to trigger Y1/Y2 and run the fan at high speed, then measure and calculate;

Speed adjustment: It is achieved through the motor pulley. Clockwise rotation of the adjustable pulley increases CFM, while counterclockwise rotation reduces CFM. The minimum/maximum rotation number of the belt should be observed (0-5 turns for A-type belt, 1-6 turns for B-type belt, and there is no minimum rotation limit for B-type belt pulleys over 6 inches).

Belt tension adjustment: The new belt needs to be re tensioned after running for 24-48 hours. The tension standard is: 2-3HP belt deflection force 5.0-7.0 pounds (35-48kPa), 5HP belt 7-10 pounds (48-69kPa), deflection amount of 1/64 inch per inch span (1.5 millimeters per 100 millimeters span).

3. Heating and cooling start-up

Heating start: Set the thermostat to level one heating (W1), triggering the operation of compressors 1 and 2 and the outdoor fan (power off L1 and L2 reversing valves in heating mode); If there is optional electric heating, the secondary heating (W2) will activate the electric heating, and the electric heating will also be activated during the defrosting cycle (W1) to maintain the supply air temperature.

Refrigeration start:

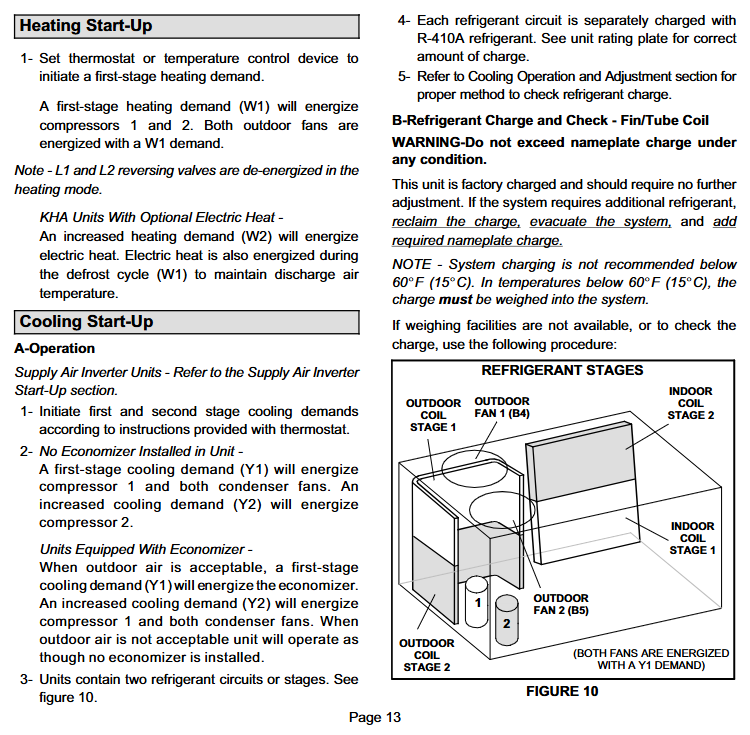

Model without energy-saving device: compressor 1 and two condenser fans are activated for primary refrigeration (Y1), and compressor 2 is activated for secondary refrigeration (Y2);

Model with energy-saving device: When the outdoor air meets the conditions, Y1 activates the energy-saving device first, and Y2 activates compressor 1 and fan when the load increases;

Refrigerant inspection: The unit factory pre charges R-410A without the need for additional charging; If it is necessary to supplement, the original refrigerant should be recovered and vacuumed first, and then filled according to the amount indicated on the nameplate (weighed and filled below 60 ° F/15 ° C). It is forbidden to exceed the nameplate filling amount.

4. Defrost control (core function of heat pump)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands