Lennox ZHA series heat pump complete set (507257-01b)

Electrical safety: power-off operation is a prerequisite - the power supply of the unit must be turned off during any maintenance to avoid the risk of electric shock or explosion; Before powering on, it is necessary to confirm that the voltage meets the range indicated on the nameplate, and the three-phase power supply must ensure phase balance (especially for models with frequency converters).

Defrost triggering and termination: triggered by the liquid tube temperature (≤ 35 ° F/1.7 ° C), the defrost controller (CMC1) starts defrosting after 60 minutes (100269-02 board) or 90 minutes (100269-04 board) of cumulative heating operation by default, lasting for 14 minutes; If the steam pressure reaches 450 PSI (3103 kPa), the defrost pressure switch will prematurely terminate defrosting.

Defrost time adjustment: The defrost interval can be set to 30/60/90 minutes through the jumper on the CMC board. The factory defaults to 60 minutes, and when there is no jumper, it defaults to 90 minutes.

Diagnostic LED: The defrost board has 2 LED lights, and the status is determined by flashing mode (normal operation: synchronous flashing; no power/board fault: all off; board fault: all on; anti short cycle lock: alternate slow flashing).

Maintenance and Service Standards

1. Regular maintenance cycle and content

Annual inspection (performed by professionals):

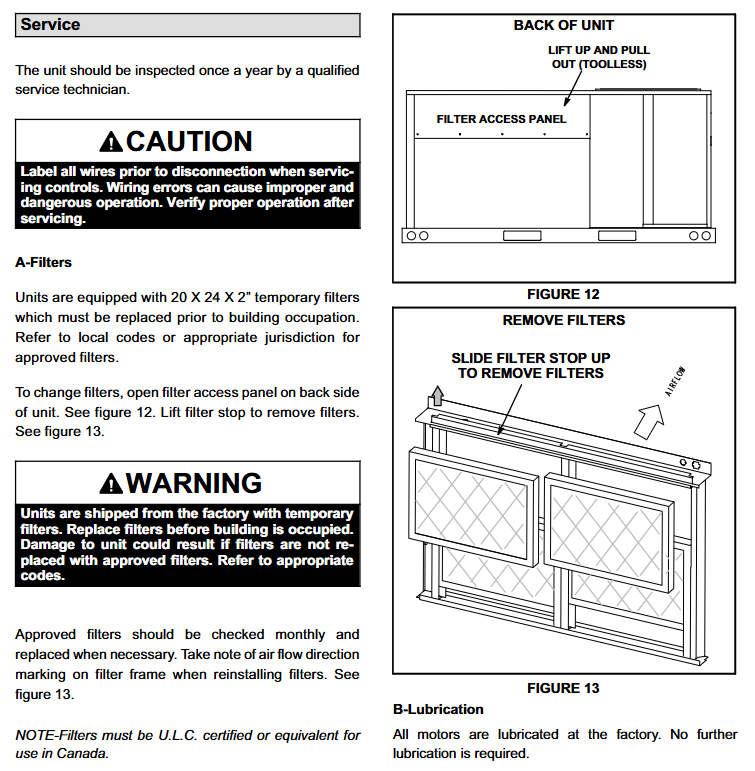

Filter element: The unit comes with a 20 × 24 × 2 inch temporary filter element at the factory. Before the building is put into use, it needs to be replaced with a compliant filter element (which requires U.L.C certification in Canada). It will be inspected monthly and replaced when it is dirty; When replacing, open the access door of the filter element on the back of the unit, lift the filter element stopper to remove it, and pay attention to the airflow direction markings.

Coil cleaning: Clean indoor coils before the start of the cooling season (using neutral or commercial coil cleaners, and avoid soaking insulation materials, filter elements, and return air ducts during flushing); The outdoor coil is cleaned annually, and the double slab coil needs to remove screws and washers, separate 3-4 inches, clean the interlayer, and then reassemble.

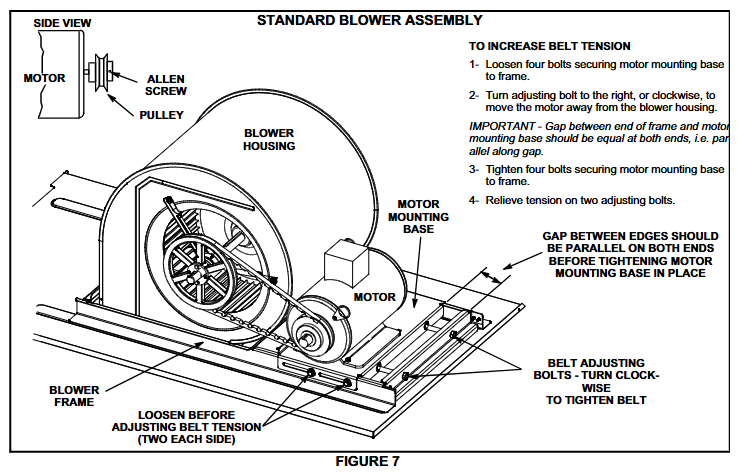

Fan wheel: Check the dust accumulation on the supply fan wheel every year, and remove the maintenance door for cleaning after power failure.

Maintenance free components: All motors are pre lubricated by the factory and do not require subsequent refueling; If the bidirectional drying filter needs to be replaced, the same model of product should be selected.

2. Precautions for troubleshooting

During maintenance, all wires should be marked before disconnecting to avoid wiring errors;

Refer to the "Defrost Control Board Diagnostic LED" and "Normal Operating Pressure Gauge" (Table 4-6, covering the suction and exhaust pressure range at outdoor temperatures of 65-115 ° F) to determine if the compressor, fan, and other components are functioning properly;

If the unit is used for temporary temperature control during construction, it must meet the conditions of "thermostat control, installation of pre filter, return air temperature 13-27 ° C", otherwise the warranty will be invalid, and the heat exchanger, air duct, filter element and other components must be thoroughly cleaned after construction is completed.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands