Mine driverless progress, laser radar let mining cars see "clearer and more thorough"

Driverless driving is leading the smart mine investment boom

Since 2021, domestic technology companies in the field of mine autonomous driving have successively released major financing and commercialization process information, indicating that industry solutions are becoming more mature.

According to public information, at the beginning of 2021, easy Control Intelligent Driving was the first to announce the completion of Pre-A round and A round of financing, with a total of more than 100 million yuan. In August 2021, the industry ushered in a financing climax. Tage Zhixing announced that within 10 months, the B round of financing has completed nearly 400 million yuan; Bolei Technology announced the financing of more than 200 million yuan; Alliance Knowledge Technology announced the completion of tens of millions of yuan Pre-A round of financing. In November 2021, Lukai Zhixing announced the completion of tens of millions of yuan Pre-A round of financing. At the beginning of this year, Huituo announced the completion of nearly 300 million yuan of C round financing, and in the previous six months, took two rounds of financing totaling more than 500 million yuan, a record high on the track.

It can be seen that mine unmanned driving is highly popular in the investment community, and is also very representative in the current smart mining field, which is an application scenario that integrates cutting-edge technology and commercial value.

IntelMining intelligent mining, mine driverless progress, Lidar let the mining car see "clearer and more thorough"

Not only that, in terms of landing, the 2021 mine unmanned field is also magnificent. Huituo has more than 20 commercial projects, the operation of more than 140 unmanned vehicles, its participation in the national energy Group Baori Xile open-pit coal mine extremely cold complex climate environment unmanned truck formation safety demonstration project first five times, become the industry vane. Tage Zhixing won the "Shenhua Nortel Victory Energy mining truck driverless technology application project", and has cooperated with Central Cooperation, Jiangxi Copper, China Mobile, North Shares, etc., landing orders of hundreds of millions of yuan. In addition, Inner Mongolia Tiechen Intelligent Equipment Co., Ltd. invested 1 billion yuan in the construction of 5G unmanned new energy mining vehicle project, Tage Zhixing invested 10 million yuan in the cooperation with the Jiujiang District people's government of unmanned new energy mining vehicle project, and Henan Yuexin invested 500 million yuan in the construction of Yuexin new energy intelligent manufacturing industrial park, etc. It will directly form tens of thousands of mining vehicles with autonomous driving capabilities, and further lay a solid foundation for the mass production of driverless mining vehicles.

The industry chain ushered in a highlight moment, laser radar can be a major task

Behind the rush of unmanned mining, the coordinated promotion of the industrial chain is a prerequisite.

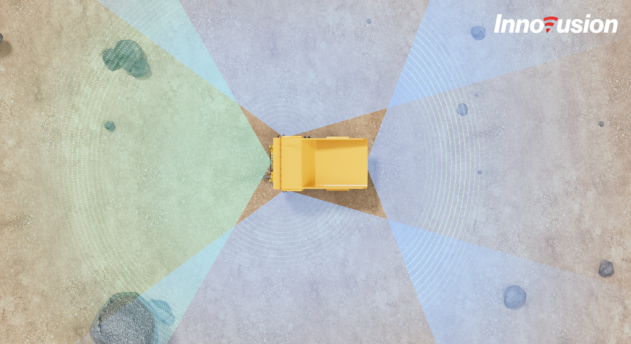

Intelligent driving is divided into three core links: perception, decision-making and control. In order to achieve intelligent driving, the first thing is to let the car see the surrounding environment clearly, that is, "perception". Therefore, as the "fire eye" of the mining car to perceive the external environment, LiDAR has also ushered in a highlight moment in the mining field. Because the laser radar senses the distance more accurately, can resist the bad weather environment, in the entire automatic driving system, it can and millimeter wave radar, camera form a favorable supplement, has become the standard of unmanned mining vehicles.

Mine scene deep landing, lidar must be grounded

The mining scene has its own industry characteristics.

With the in-depth understanding of application scenarios from mining enterprises to technology enterprises to all links of the supply chain, it is obvious that the requirements of all parties for the real landing are becoming more and more demanding. In the face of the generally harsh working environment in the mining area, the severe cold and hot summer, sand, rain and snow, the strong vibration caused by the rugged road and the unexpected situation that may occur at any time, the core sensor Lidar of the unmanned mining card is a great test, which puts forward high requirements for the functional quality of the product.

The first is to let the car "see further", which requires liDAR to have a very long detection range. The general detection distance of vehicle lidar is 150 meters, compared with the length of the one-way road in the large mining area, the "visual distance" of the mining car is obviously relatively small, and the detection distance of 150 meters is obviously not enough. If the detection distance can be greatly increased, it can well help solve the mining card unmanned driving problems such as unstructured road path planning, horizontal and vertical joint control of uneven roads, and multi-vehicle cooperative scheduling.

The second is to let the mining car "see more clearly", which requires liDAR to have a high resolution. The road conditions of the mine are complex, many vehicles will be damaged by some obstacles such as stones during the driving process, and the industry knows that the cost of replacing the tire of the mine car is very high, if the laser radar can accurately perceive small objects such as bricks 100 meters away, accurately identify small obstacles on the non-paved road in the mining area, then it can effectively help the mine car to avoid obstacles in time. While reducing tire losses, it can also greatly prevent safety production risks.

The third is to let the mining car "see more thoroughly", which requires the laser radar to have super-strong dust penetration perception. The production environment of the mine is harsh, the dust generated in the production and transportation process seriously affects the effective visual distance of the driver, and the production efficiency will be greatly reduced in the case of wind, sand, rain and snow. As the "eyes" of the mining car, Lidar needs to extend the perception of the mining car from a technical point of view to truly achieve the effect of "lifting the clouds and seeing the sun".

The fourth is to make the car "more solid and reliable", which requires the liDAR to stand the test of the harsh environment. Mine non-standard road bumps, the test of the extreme cold weather in the north, etc., need the vehicle lidar to adapt to the environment well, but also put forward higher requirements for the rapid response ability of the manufacturer's after-sales maintenance.

From this point of view, automatic driving in mine closed scenarios is not low for liDAR manufacturers.

At present, major enterprises have polished their own technical routes to meet the needs of real scenes with the best results. Among them, Innovusion (Turdaton) selected a hybrid solid-state technology route and 1550nm light source to launch Falcon Lidar. Its maximum detection distance can reach 500 meters, and its three-echo technology has strong penetration of smoke and dust, and can still maintain high performance under weather conditions such as wind, sand, rain and snow, thus greatly enhancing the decision-making ability of the mining car. At the same time, it is also adapted to the extremely cold and high temperature environment, can cover the working condition of -40~85 ° C, and supports the cold start of -40 ° C, especially suitable for the extreme cold working environment of the open-pit mine in northern China, to ensure that the LiDAR can work normally throughout the year.

Innovusion Falcon Lidar

In terms of reliability, Innovusion Falcon Lidar, as the standard lidar of all WEilai ET7 systems, has been verified to ensure product stability and extend product life cycle under extremely volatile and high-intensity vibration working environment in mines, thus making Innovusion have a good comprehensive cost advantage. In addition, as a LiDAR enterprise with a complete supply chain in China, Innovusion's localization and rapid service response ability is also praised. Compared with the longer delivery and repair period of some manufacturers' products, Innovusion can greatly improve customers' sensitivity.

IntelMining intelligent mining, mine driverless progress, Lidar let the mining car see "clearer and more thorough"

An unmanned mine equipped with Innovusion Lidar

In addition, it is worth mentioning that at the International Consumer Electronics Show in early January 2022, Innovusion announced the first in-car image-level medium-short range Lidar Robin. With its excellent performance and flexible adaptation, Robin will further enable the unmanned mining card sensing system in the future, establishing effective safety and performance guarantees for the all-round sensing scheme around the mining card.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands