Building intelligent mines and pioneering mining -- Shougang Xingshan Iron Mine

Since its completion, Xingshan Iron Mine has adhered to the implementation of the national industrial policy, taken "marketization, automation, informatization, and strengthening the management foundation" as the main line of work, focused on the "safety, health, green, and harmonious" mine construction, promoted all-personnel innovation, and gradually realized mechanization, automation, and digital mining mountain. Among the 31 mining mountains in China, 1 ranked second and 2 ranked third among 12 comparable indicators. In recent years, Xingshan Iron Mine has been established as the first batch of "mechanized replacement, automation reduction" science and technology strong safety project demonstration enterprises, and has won the fifth National metallurgical mine excellent factory, the national iron and steel industry advanced collective, the seventh metallurgical mine "Top Ten factories" and other honorary titles. Xingshan Iron Mining development Zone was awarded the "Pioneer of Workers" by the All-China Federation of Trade Unions.

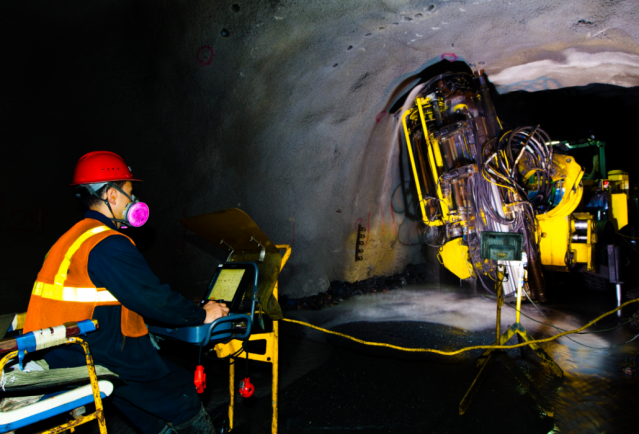

In the early stage of mine construction, Xingshan Iron Mine determined the construction target of the ground mining project to take the new industrialization development road. Relying on the advantages of Shou Mine in informatization and automation, adhere to innovation and leadership, pay attention to the integration of informatization, automation and mining technology, and promote the construction of three systems: mining mechanization, rail transportation and automation, large fixed system and unattended facilities. Completed the renovation of 14 specific projects such as the unattended -480-meter water pump room, remote control of -330-meter water pump room, remote control of auxiliary shaft Matou gate, and realized the integration of production site control. Comprehensive use of modern Internet of Things technology, three-network integration technology, wireless positioning technology, remote control technology, completed the production execution, automatic control, safety "six systems", information management "four systems" platform construction, to achieve the basic information digitization, mining equipment modernization, production implementation visualization, management control integration, decision support platform. -180 meters horizontal electric locomotive to achieve remote control, became the first domestic, filled the domestic technology gap, won the first prize in metallurgical mining science and technology; -330m horizontal mud discharge system transformation, becoming the second domestic mechanized mud discharge underground iron mine; The "six safety systems" were the first to pass the acceptance of the State Administration of Work Safety in non-coal mines in China, and became a demonstration project for the digital construction of underground metal mines in the country. "Construction of Six Safety Systems for Underground Mining Iron Ore and Application of automation" won the third prize of Science and Technology of China Iron and Steel Industry Association and China Metallurgical Mining Enterprise Association. The fully automatic mechanical makeup truck was successfully developed and became the first mine in China to realize mechanical makeup in underground mines, and the project won the first prize of China Blasting Industry Association.

Xingshan Iron Mine will continue to take less humanized, unmanned, remote, remote, efficient, intelligent and intelligent as the main line of development, accelerate the construction of smart mines, and strive to achieve intelligent operation of process areas, full coverage of underground communication, remote control of equipment in stope areas and dynamic automatic data upload and update, and healthy management of ground mining equipment.

Science and technology, management innovation implementation of "two-wheel drive", innovation studio to build innovative talent cultivation platform, rationalization suggestions, staff advice activities to stimulate the enthusiasm for active innovation, these five innovative work carriers to achieve accurate positioning, functional complementarity, integrated development, and strive to create an innovative mining mountain. Adhere to the innovation competition with the theme of "endless creativity · Wisdom in Xingshan", explore the learning and innovation studio construction mechanism, encourage team learning, stimulate all staff innovation, and provide solid support for production and management to improve efficiency, efficiency and efficiency.

In recent years, Xingshan Iron Mine has won more than 70 technological and management innovation awards, including 2 national awards, 5 industry association awards, 3 Beijing level awards, 8 new and invention patents, among which "Research on the Occurrence Form and Distribution Geological Characteristics of Xingshan Iron Ore Deposit of Shougang" won the second prize of Metallurgical Mining Science and Technology of China Metallurgical Mining Enterprise Association. "Safe and efficient blasting" Four modernization "management of Metallurgical underground mines won the second prize of the 24th National Enterprise Management Modernization Innovation Achievement, China's Best Management Innovation Practice Award," Xingshandi Best cut-off grade Research and Practice "won the third prize of Metallurgical Mining Science and Technology of China Metallurgical Mining Enterprise Association. "Construction and Implementation of Essential Safety Management System of Metallurgical underground Mine Enterprises" won the first prize of the 33rd Beijing Enterprise Management Modernization Innovation Achievement.

As a resource-based enterprise, Xingshan Iron Mine adheres to the core values of "people-oriented, the pursuit of excellence, and the creation of maximum value with limited resources" in the first mine. In order to reduce resource loss, the waste stone after dry selection is crushed to produce building materials for export and achieve tail-free discharge. Mine water recycling, for mining and mineral processing production, utilization rate of 100%, annual income of more than one million yuan. The simultaneous use of geothermal energy to solve the problem of office heating and cooling, saving energy of 4 million KWH per year. The use of new technology to save energy and reduce consumption, adopt frequency conversion technology to control the motor of the fan station, and save about 3 million KWH of electricity annually. Build and upgrade the comprehensive utilization of solid waste resources production line, separate the mixed rocks in the ore, process them into different specifications of building ballast, and realize resource reuse. The annual processing capacity reaches 700,000 tons, and the annual profit of the enterprise is more than one million. Reasonable control of the cut-off grade of ore drawing, reduce the consumption of geological ore, effectively use and save mineral resources, save 1.49 million tons of geological ore in three years, extend the service life of 5 months.

In order to effectively fulfill social responsibilities and maintain a good social image of enterprises, Xingshan Iron Mine has always adhered to the overall ecological environment restoration and management principle of "focusing on green, highlighting benefits, focusing on results, and improving image", and the working standard of "managing one region and green one region". With the "five green actions" of "repairing green" in advance, "moving green" in a timely manner, concentrating on "planting green", strengthening "replenling green" and "protecting green" as the starting point, we carried forward the spirit of Saihanba, vigorously carried out the restoration and management of the ecological environment of mines, and realized the organic combination of land reclamation and plant beautification. In recent years, a total of 1.80100 million square meters of reclamation and greening tasks have been completed, and more than 2.07 million seedlings of various types have been planted. The green coverage rate of the controllable area in the mining area has reached 100%, and it has won the title of "garden-style unit" in Tangshan City, Hebei Province.

The implementation of the "flag gathering" project of the Party committee holding the flag, the branch fighting for the flag, and the Party members embroidering the flag, to create the "flag leading force gathering" party building brand, from the six aspects of leading learning, promoting dry, supervising, educating, innovation, and concentration, respectively, focusing on the solid foundation, leading the majority of cadres and workers to launch, organize, and refine, and condense the wisdom and strength to the tasks of mining construction. In order to build a safe, intelligent, efficient, green and happy Xingshan, we will promote the high-quality development of Xingshan Iron Mine. Build a "seven-party linkage" responsibility system for the construction of party style and clean government, including the Party committee casting integrity, the discipline inspection committee supervising integrity, professional integrity, cadres trekking integrity, employees promoting integrity, families protecting integrity, and suppliers helping integrity, create a "six-in-one" cultural system of execution, collaboration, learning, innovation, striving to be first, and gratitude culture, and establish a party building innovation as the guide wheel and science and technology and management innovation as the two driving wheels. The five micro-innovations of small innovation, small transformation, small ideas, tips and small inventions are the "eight rounds of rotation" innovation system of the five rear driving wheels, the implementation of talent construction "English extraction project", the cohesion of entrepreneurship consensus, the motivation of innovation, and the development of excellence. The implementation of the "Care for employees · Grateful Xing Shan" theme education activities, always uphold the "where the needs of employees, where to do the work", the care of employees normalize and institutionalize, actively carry out cultural care, seasonal care, incentive care and considerate care, and concentrate on solving the hot spots, difficulties and focus issues of concern to employees. Establish a "clear, visit, talk, help" mechanism, do a good job of the "voice" of the masses of workers, the "civilian car" of demand, the "weather vane" of the officers, and further enhance the sense of gain and happiness of the workers. Condense the "team construction culture" and promote the "all staff health plan". Actively carry out various forms of recreational and sports activities that employees enjoy, and enrich the leisure cultural life. 3 people won the national metallurgical industry type champion, 5 people won the "National Technical expert", 6 people won the "National metallurgical industry technical expert" title,1 person won the "capital citizen learning star",1 person won the national iron and steel industry model worker.

Forge ahead with the "14th Five-Year Plan" and start a new journey. Xingshan Iron Mine will continue to build a mining demonstration base, talent training base, science and technology innovation base, create a new situation on the road of building a safe, efficient, intelligent, green and happy Xingshan, and make new contributions to the third great development journey of Shougang Mining Company

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands