Building intelligent mines and pioneering mining -- Shougang Xingshan Iron Mine

Since its completion, Xingshan Iron Mine has adhered to the implementation of the national industrial policy, taken "marketization, automation, informatization, and strengthening the management foundation" as the main line of work, focused on the "safety, health, green, and harmonious" mine construction, promoted all-personnel innovation, and gradually realized mechanization, automation, and digital mining mountain. Among the 31 mining mountains in China, 1 ranked second and 2 ranked third among 12 comparable indicators. In recent years, Xingshan Iron Mine has been established as the first batch of "mechanized replacement, automation reduction" science and technology strong safety project demonstration enterprises, and has won the fifth National metallurgical mine excellent factory, the national iron and steel industry advanced collective, the seventh metallurgical mine "Top Ten factories" and other honorary titles. Xingshan Iron Mining development Zone was awarded the "Pioneer of Workers" by the All-China Federation of Trade Unions.

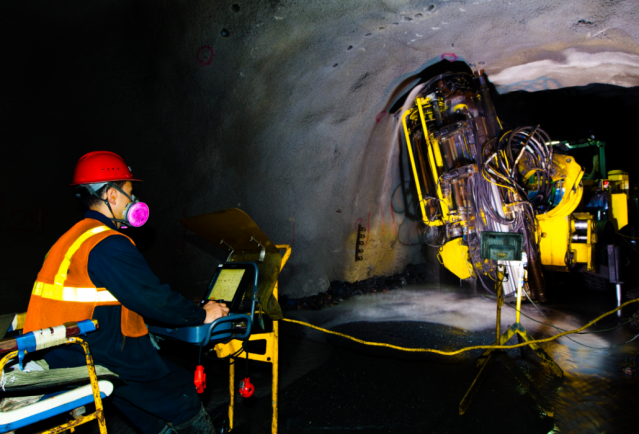

In the early stage of mine construction, Xingshan Iron Mine determined the construction target of the ground mining project to take the new industrialization development road. Relying on the advantages of Shou Mine in informatization and automation, adhere to innovation and leadership, pay attention to the integration of informatization, automation and mining technology, and promote the construction of three systems: mining mechanization, rail transportation and automation, large fixed system and unattended facilities. Completed the renovation of 14 specific projects such as the unattended -480-meter water pump room, remote control of -330-meter water pump room, remote control of auxiliary shaft Matou gate, and realized the integration of production site control. Comprehensive use of modern Internet of Things technology, three-network integration technology, wireless positioning technology, remote control technology, completed the production execution, automatic control, safety "six systems", information management "four systems" platform construction, to achieve the basic information digitization, mining equipment modernization, production implementation visualization, management control integration, decision support platform. -180 meters horizontal electric locomotive to achieve remote control, became the first domestic, filled the domestic technology gap, won the first prize in metallurgical mining science and technology; -330m horizontal mud discharge system transformation, becoming the second domestic mechanized mud discharge underground iron mine; The "six safety systems" were the first to pass the acceptance of the State Administration of Work Safety in non-coal mines in China, and became a demonstration project for the digital construction of underground metal mines in the country. "Construction of Six Safety Systems for Underground Mining Iron Ore and Application of automation" won the third prize of Science and Technology of China Iron and Steel Industry Association and China Metallurgical Mining Enterprise Association. The fully automatic mechanical makeup truck was successfully developed and became the first mine in China to realize mechanical makeup in underground mines, and the project won the first prize of China Blasting Industry Association.

Xingshan Iron Mine will continue to take less humanized, unmanned, remote, remote, efficient, intelligent and intelligent as the main line of development, accelerate the construction of smart mines, and strive to achieve intelligent operation of process areas, full coverage of underground communication, remote control of equipment in stope areas and dynamic automatic data upload and update, and healthy management of ground mining equipment.

Science and technology, management innovation implementation of "two-wheel drive", innovation studio to build innovative talent cultivation platform, rationalization suggestions, staff advice activities to stimulate the enthusiasm for active innovation, these five innovative work carriers to achieve accurate positioning, functional complementarity, integrated development, and strive to create an innovative mining mountain. Adhere to the innovation competition with the theme of "endless creativity · Wisdom in Xingshan", explore the learning and innovation studio construction mechanism, encourage team learning, stimulate all staff innovation, and provide solid support for production and management to improve efficiency, efficiency and efficiency.

In recent years, Xingshan Iron Mine has won more than 70 technological and management innovation awards, including 2 national awards, 5 industry association awards, 3 Beijing level awards, 8 new and invention patents, among which "Research on the Occurrence Form and Distribution Geological Characteristics of Xingshan Iron Ore Deposit of Shougang" won the second prize of Metallurgical Mining Science and Technology of China Metallurgical Mining Enterprise Association. "Safe and efficient blasting" Four modernization "management of Metallurgical underground mines won the second prize of the 24th National Enterprise Management Modernization Innovation Achievement, China's Best Management Innovation Practice Award," Xingshandi Best cut-off grade Research and Practice "won the third prize of Metallurgical Mining Science and Technology of China Metallurgical Mining Enterprise Association. "Construction and Implementation of Essential Safety Management System of Metallurgical underground Mine Enterprises" won the first prize of the 33rd Beijing Enterprise Management Modernization Innovation Achievement.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands