UE 54 series pressure, vacuum, and temperature switches

D21BS 0-150 ° F (-17.8-65.6 ° C) 200 ° F (93.3 ° C) 5 ° F/5 ° C 3/8 × 7-1/4 inch 304 stainless steel bulb+capillary tube

Certification and Compliance

North American certification:

CULus certification: Pressure models (J54, H54, etc.) comply with UL 508, CSA C22.2 No.14 (document number E42272); Temperature models (B54, C54, etc.) comply with UL 873, CSA C22.2 No.24 (document number E10667);

CURus certification: Open models (J54S, B54S, etc.) are at the "approved" level and comply with the same standards mentioned above.

European certification:

Low Voltage Directive (LVD): 2006/95/EC (before April 20, 2016), 2014/30/EU (after April 20, 2016), except for models below 50VAC/75VDC;

Pressure Equipment Directive (PED): 97/23/EC (before April 20, 2016), 2014/34/EU (after April 20, 2016), except for models below 7.5psi;

Note: Open models are not subject to LVD control.

Ordering rules and options

(1) Model composition

You need to combine "Type+Model+Option", for example: J54-25-0140 (J54 Type+25 Model+0140 Option).

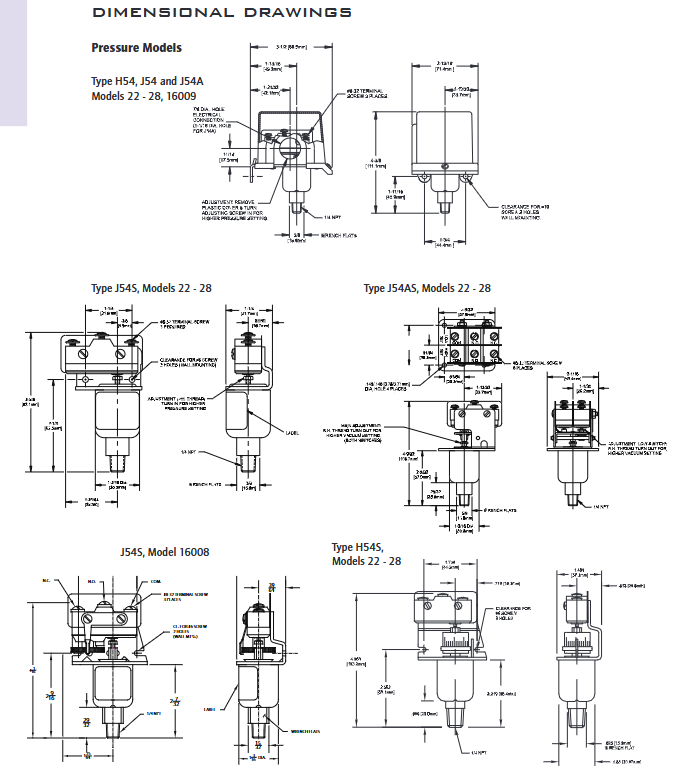

Type selection: Classified by "Protection+Output+Adjustment Method", the core types are as follows:

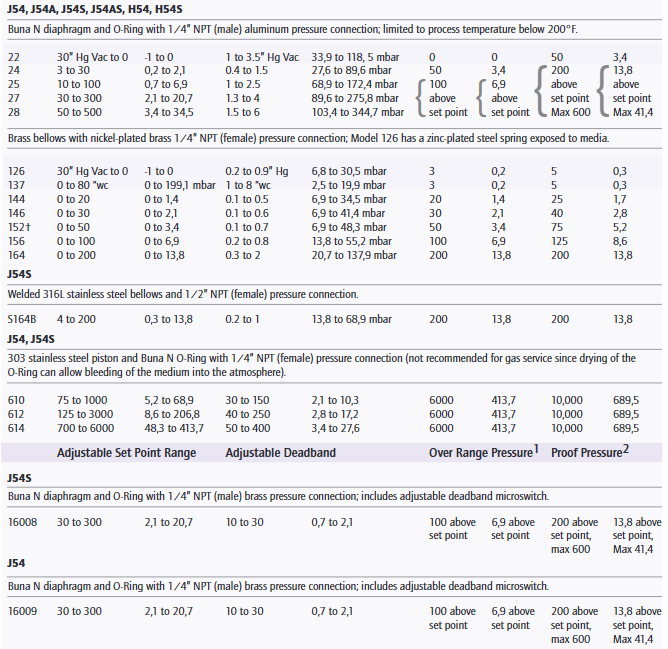

|Type | Application Scenario | Number of Output Channels | Protection Level | Adjustment Method|

|J54 | Pressure Monitoring, Conventional Closed Scenarios | 1-channel SPDT | NEMA 1 | Internal Hexagonal Screw (No Scale)|

|J54A | Pressure monitoring, dual output requirement | 2-channel SPDT | NEMA 1 | Hexagonal socket screw (without scale)|

|H54 | Pressure monitoring, requiring intuitive adjustment | 1-channel SPDT | NEMA 1 | Reference dial|

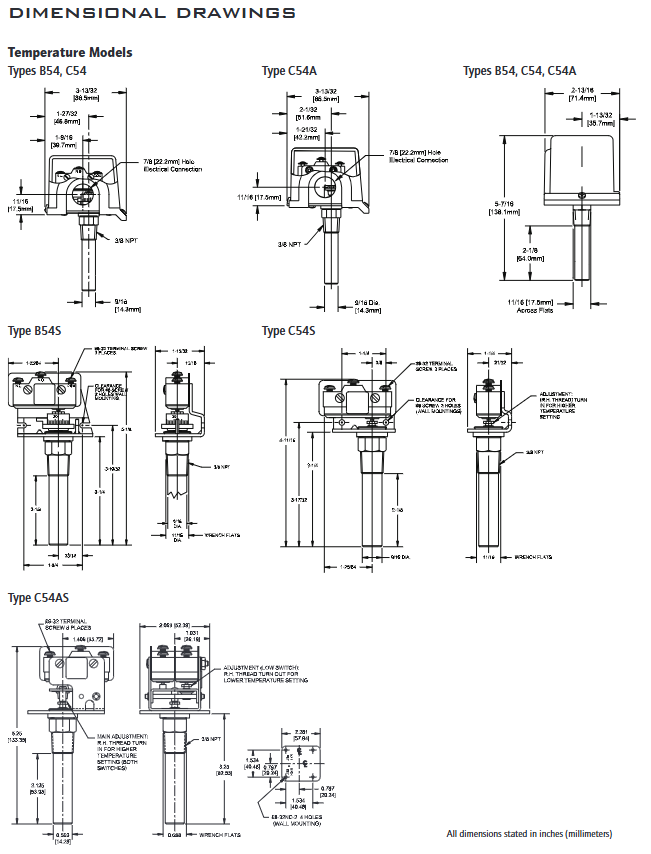

|B54 | Temperature monitoring (probe type), intuitive adjustment | 1-channel SPDT | NEMA 1 | Reference dial|

|E54 | Temperature monitoring (bulb+capillary), intuitive adjustment | 1-channel SPDT | NEMA 1 | Reference dial|

|With the suffix "S" (such as J54S, B54S) | Customized shell scene | 1/2 SPDT | Open | Corresponding adjustment method|

Option key code:

|Option code | Function description | Applicable restrictions|

|0140 | Gold plated contacts (1A 125VAC resistive) | Not suitable for 16008-16009|

|0500 | Narrow dead zone (5A 125/250VAC resistive) | Not applicable to B54, J54A, 16008-16009, etc|

|1530 | External manual reset (15A 125/250/480VAC) | Only applicable to H54, some pressure models, not applicable to open models|

|2000 | High current output (20A 125/250/480VAC) | Not suitable for 16008-16009|

|M501 | Polysulfone pressure connection (1/2 "NPT male x 1/8" NPT female) | Not suitable for pressure and temperature models such as 126-164 and 610-614|

(2) Additional temperature model options

Connection accessories: Provide 1/2 inch NPT union (brass/stainless steel), thermocouple sleeve (such as W191:1/2 inch NPT x 4 inch length, brass);

Scale unit: optional Celsius dial (only supported for some temperature models);

Identification label: Optional stainless steel label (up to 2 lines, 25 characters per line).

Installation and usage precautions

Extreme parameter control:

It is strictly prohibited to exceed the "withstand voltage" and "maximum temperature" limits (even short-term impact), and continuous operation should be within the "adjustable set point range" to avoid frequent switching near the limit value to extend the service life;

The ambient temperature should not exceed the product label range, and electrical connection holes should be sealed in humid environments to prevent water ingress.

Safety design:

Critical safety scenarios (such as personnel/equipment protection) require the configuration of backup switches and the installation of high and low limit protection to prevent loss of control;

The range of the set point should be reasonably selected to avoid unsafe conditions of the system caused by misoperation (such as excessive pressure and temperature).

Maintenance requirements:

Regularly verify the drift of the set point, and immediately check if any display abnormalities or action faults are found;

Do not disassemble or modify the product on your own. If customization is required, please contact the UE manufacturer;

Electrical wiring must comply with local regulations, and wire specifications should refer to the installation manual to avoid overload (the first overload may damage the switch).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands