Powell PowlVac ® CDR&GCB Series 4 Vacuum Circuit Breaker

Powell PowlVac ® CDR&GCB Series 4 Vacuum Circuit Breaker

Product Core Overview

PowlVac ® Series 4 vacuum circuit breaker is a new generation of metal armored vacuum circuit breaker launched by Powell Industries in the United States, suitable for medium and high voltage power systems ranging from 5kV to 38kV. Its design originated from the first PowlVac circuit breaker in 1982 and has been upgraded and optimized for multiple generations, combining compactness, high reliability, and low maintenance. The product focuses on 'Powered by Safety' ®” The concept provides multiple customized options (such as narrow body design, manual/automatic rack and pinion transmission, intelligent monitoring equipment), which can adapt to the space limitations of existing equipment and meet the protection needs of medium and high voltage circuits in industrial, power and other fields.

Safety regulations and qualification requirements

(1) Definition of Signal Words (in accordance with ANSI Z535.4-2007)

Clarify the risk levels of different safety warnings and guide personnel to identify the degree of danger:

DANGER: Emergency and dangerous situation, failure to avoid may result in death or serious injury.

Warning: Potential dangerous situations that may result in death or serious injury if not avoided.

CAUTION (with safety warning symbol): A dangerous situation that may cause minor/moderate injury.

CAUTION (unsigned): Precautions for operations unrelated to personal injury.

NOTICE: It only involves equipment operation specifications and has no safety risks.

(2) Qualified personnel qualifications (compliant with NFPA 70E) ®)

Operation and maintenance personnel must meet the following conditions:

Having received training on the construction and operation of high-voltage equipment, able to identify and avoid risks.

Master the safety operation procedures such as circuit on/off, grounding, and LOTO (Tag Out).

Familiar with the use of personal protective equipment (PPE) such as insulated gloves, safety helmets, and arc resistant clothing.

Have basic first aid skills.

(3) Key safety rules

Strictly prohibit live operation: all power sources must be disconnected before maintenance to ensure equipment grounding; Do not touch equipment when the control circuit is live.

Energy storage mechanism protection: The equipment adopts an energy storage spring mechanism. When releasing/operating, it is necessary to ensure that personnel and tools are kept away from moving parts to avoid accidental release of the spring causing injury.

Isolation requirement: It is not allowed to use only a disconnected circuit breaker as a means of isolating high-voltage circuits. The circuit breaker must be returned to the "test/disconnect" position or completely withdrawn.

X-ray risk: During high-voltage testing, the vacuum arc extinguishing chamber may generate X-rays. Personnel must maintain a distance of at least 1 meter from the equipment, and the circuit breaker must be fully opened or closed (half open testing is prohibited).

Interlock protection: The equipment is equipped with multiple interlocks (such as rack drive interlock, secondary disconnection interlock), and it is prohibited to modify or bypass the interlock device. In case of abnormalities, the manufacturer should be contacted.

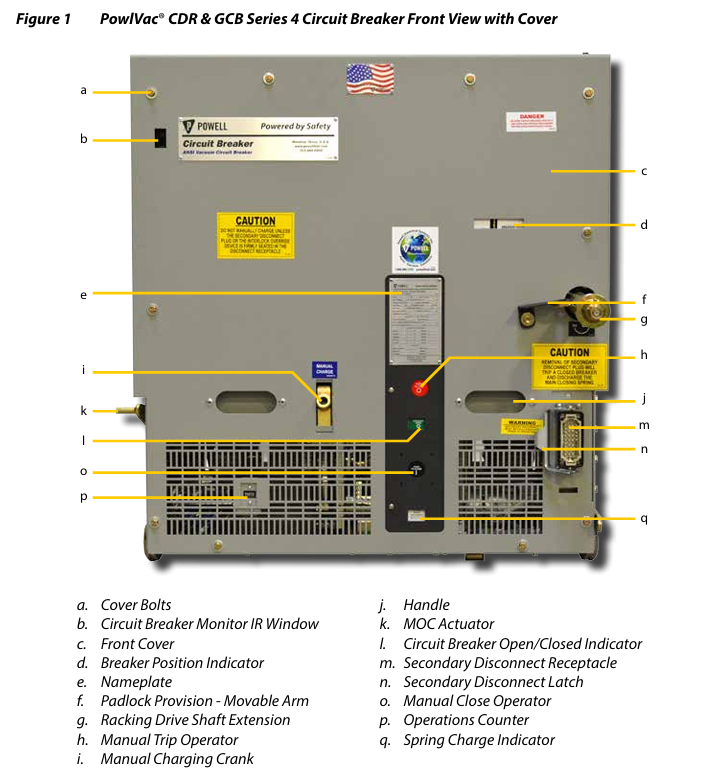

Equipment Description and Core Components

(1) Basic Structure and Function

The circuit breaker adopts a sealed vacuum arc extinguishing chamber to control the main circuit. The main circuit is connected to a multi contact primary disconnecting device through parallel copper busbars, and is supported by insulators as a whole; The front of the equipment is an operation panel (including indicator lights and manual operating components), which contains an energy storage mechanism, a rack and pinion transmission mechanism, an interlocking device, and auxiliary switches. It can switch between the "test/disconnect" and "connect" positions and is compatible with metal armored switchgear.

(2) Detailed explanation of core components

Stored Energy Mechanism

Mechanical structure: composed of main closing spring, camshaft, ratchet mechanism, retaining claw, etc., energy is stored by compressing the spring through a charging motor or manual crank, and the energy is released when closing to drive the vacuum arc extinguishing chamber contact to close; Equipped with a disconnect spring, it releases energy during disconnection to achieve rapid disconnection.

Electrical control: including charging motor, motor cut-off switch, anti pump relay (to avoid repeated opening and closing caused by continuous closing signals), closing coil, opening coil (primary/secondary), undervoltage trip device (optional), supporting 24VDC-250VDC/120VAC-240VAC control voltage.

Rack mechanism

Function: Drive the circuit breaker to switch between the "test/disconnect" and "connect" positions inside the switchgear, while controlling the opening and closing of the cabinet panel.

Position indication: The "Circuit Breaker Position Indicator" on the front panel displays the current status (fully displaying "BREAKER CONNECTED" as the connection position and "BREAKER TEST/DISCONNECT" as the test position).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands