UE 54 series pressure, vacuum, and temperature switches

UE 54 series pressure, vacuum, and temperature switches

Product Core Overview

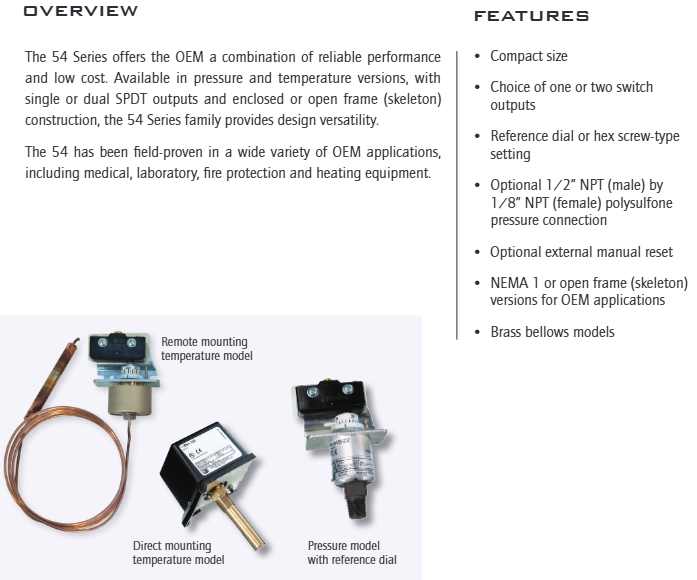

The UE (United Electric Controls) 54 series is an OEM grade switch product that balances reliability and low cost, covering three monitoring types: pressure, vacuum, and temperature. It offers single/double SPDT (single pole double throw) output options and supports enclosed (NEMA 1 protection) or open (skeleton) structural designs. The product, with its compact size and flexible configuration, has been validated on-site in various fields such as medical equipment, laboratory instruments, fire protection, heating equipment, etc. It can meet the safety alarm and shutdown control requirements in different scenarios.

Core Features

Size and configuration flexibility:

Compact size, suitable for OEM applications with limited space;

Output options include 1 or 2 SPDT quick action switches, with a dual switch range separation of up to 100%, supporting "normally open" or "normally closed" wiring;

The setting method can be selected from the reference dial (intuitive adjustment) or the hexagonal socket screw (precise adjustment) to meet different operating habits.

Connection and protection options:

Pressure connection: optional 1/4 inch NPT (male/female), 1/2 inch NPT (female), some models provide polysulfone material 1/2 inch NPT (male) x 1/8 inch NPT (female) adapters;

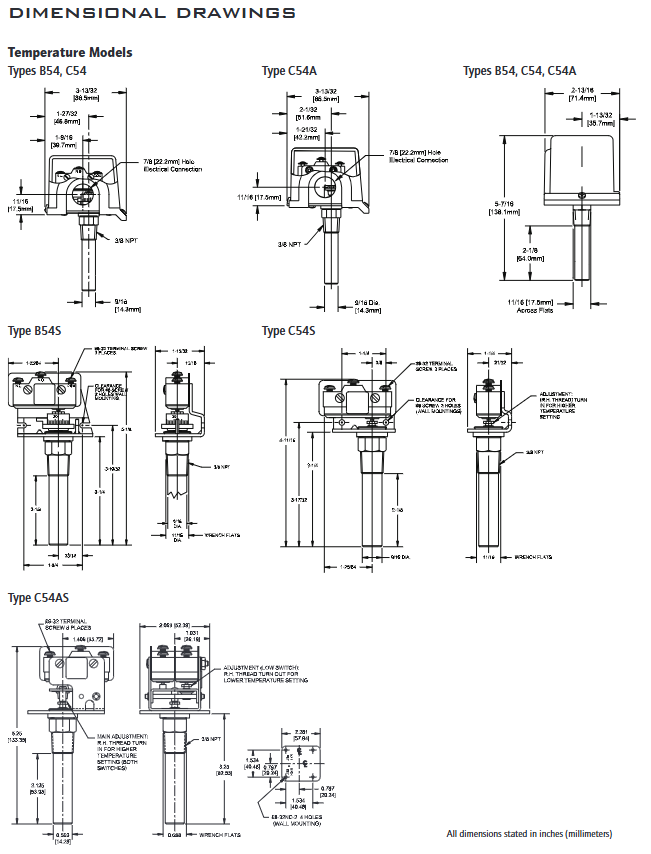

Temperature component: equipped with a 6-foot copper or 304 stainless steel capillary tube, brass immersion probe, filled with non-toxic oil;

Protection level: Closed models (such as J54, B54) comply with NEMA 1 standards, while open models (with "S" suffix, such as J54S) have no protection and are suitable for customized enclosure scenarios.

Performance advantages:

High precision: The temperature setpoint deviates by less than 1% of the range as the ambient temperature changes (50 ° F/28 ° C), and the repeatability of the pressure/temperature setpoint reaches ± 1% of the full range (± 1.5% for 610-614 pressure models);

Anti interference: capable of withstanding 15G (10 milliseconds) impact, 2.5G (5-500Hz) vibration, and no drift at the set point;

Optional features: Some models support external manual reset (only reset when pressure/temperature rises) Viton ® Enhanced options such as sealing material (suitable for special media).

Detailed technical specifications

(1) Environmental and physical parameters

Parameter category specification description

Environmental temperature range, pressure model:

-126-164 S164B、 610-614: -40 to 160 ° F (-40 to 71 ° C)

-22-28, 16008-16009:0 to 160 ° F (-18 to 71 ° C)

Temperature model: -40 to 160 ° F (-40 to 71 ° C)

Anti impact/vibration impact: The set point can be repeated after 15G (10ms); Vibration: The set point can be repeated after 2.5G (5-500Hz)

Enclosure Material Closed Model (J54, B54, etc.): Black Lexan ® (Polycarbonate), strong weather resistance

Weight approximately 12 ounces (approximately 340g)

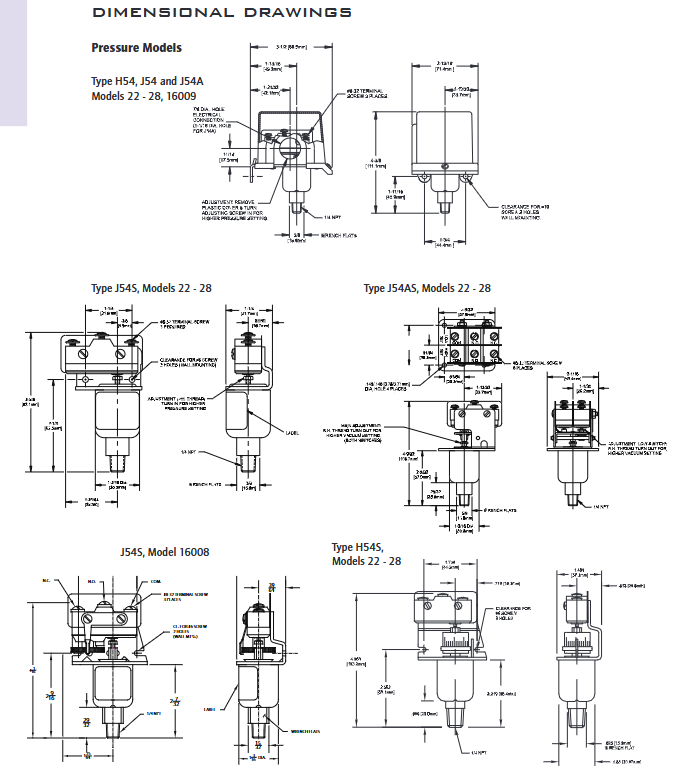

Electrical connection aperture: J54/H54/C54, etc. are 7/8 inches, J54A is 1-1/16 inches

(2) Switches and electrical parameters

Parameter specifications

Switch output 1 or 2 SPDT channels, dual switch can be independently set, separation up to 100% range

Electrical rating - AC: Conventional model 15A 125/250/480VAC (resistive); 16008-16009 model 20A 480VAC

-DC: 24-30VDC (2A resistive/1A inductive), 125VDC (0.5A resistive/0.03A inductive)

(Note: DC capability is limited, special requirements need to be consulted with the manufacturer)

Dead zone (temperature/pressure difference) temperature model: Under laboratory conditions (70 ° F circulating bath, heating rate 0.5 ° F/minute), it is usually 1% of the range

Pressure model: varies with the model, for example, the 22 model is 1-3.5 inches of mercury vacuum, and the 614 model is 50-400psi

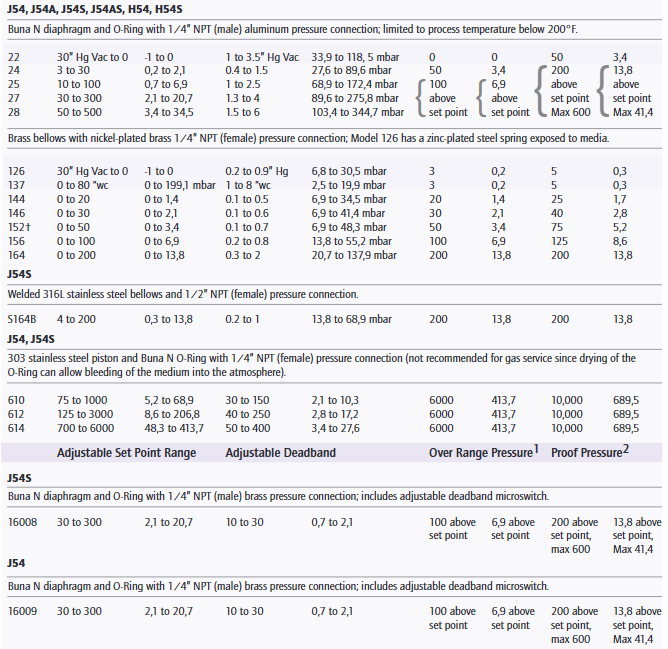

(3) Key parameters of pressure models (some core models)

Model adjustable set point range dead zone over range pressure (continuous withstand) withstand pressure (occasional withstand) pressure connection

22 30 inch mercury vacuum to 0psi (-1 to 0bar) 1-3.5 inch mercury vacuum (33.9-118.5mbar) 0psi (0bar) 50psi (3.4bar) 1/4 inch NPT (male), nitrile rubber diaphragm

25 10-100psi (0.7-6.9bar) 1-2.5psi (68.9-172.4mbar) 100psi (6.9bar) Exceeding the set point (no fixed value) 1/4 inch NPT (male), nitrile rubber diaphragm

126 30 inches of mercury vacuum to 0psi (-1 to 0bar) 0.2-0.9 inches of mercury (6.8-30.5mbar) 3psi (0.2bar) 5psi (0.3bar) 1/4 inch NPT (female), brass bellows

614 700-6000psi(48.3-413.7bar) 50-400psi(3.4-27.6bar) 6000psi(413.7bar) 10000psi(689.5bar) 1/4 Inch NPT (female), 303 stainless steel piston

S164B 4-200psi(0.3-13.8bar) 0.2-1psi(13.8-68.9mbar) 200psi(13.8bar) 200psi(13.8bar) 1/2 Inch NPT (female), 316L stainless steel corrugated pipe

(4) Key parameters of temperature models (some core models)

Model adjustable set point range, maximum temperature scale, indexing probe/bulb size (NPT x length), material

103 0-225 ° F (-17.8-107.2 ° C) 250 ° F (121.1 ° C) 10 ° F/5 ° C 3/8 × 2-1/8 inch brass probe

D20BC -130-120 ° F (-90-48.9 ° C) 170 ° F (76.7 ° C) 10 ° F/5 ° C 3/8 × 4-1/2 inch copper bulb+capillary tube

D23BS 150-650 ° F (65.6-343.3 ° C) 700 ° F (371.1 ° C) 25 ° F/10 ° C 3/8 × 4 inch 304 stainless steel bulb+capillary tube

D21BS 0-150 ° F (-17.8-65.6 ° C) 200 ° F (93.3 ° C) 5 ° F/5 ° C 3/8 × 7-1/4 inch 304 stainless steel bulb+capillary tube

Certification and Compliance

North American certification:

CULus certification: Pressure models (J54, H54, etc.) comply with UL 508, CSA C22.2 No.14 (document number E42272); Temperature models (B54, C54, etc.) comply with UL 873, CSA C22.2 No.24 (document number E10667);

CURus certification: Open models (J54S, B54S, etc.) are at the "approved" level and comply with the same standards mentioned above.

European certification:

Low Voltage Directive (LVD): 2006/95/EC (before April 20, 2016), 2014/30/EU (after April 20, 2016), except for models below 50VAC/75VDC;

Pressure Equipment Directive (PED): 97/23/EC (before April 20, 2016), 2014/34/EU (after April 20, 2016), except for models below 7.5psi;

Note: Open models are not subject to LVD control.

Ordering rules and options

(1) Model composition

You need to combine "Type+Model+Option", for example: J54-25-0140 (J54 Type+25 Model+0140 Option).

Type selection: Classified by "Protection+Output+Adjustment Method", the core types are as follows:

|Type | Application Scenario | Number of Output Channels | Protection Level | Adjustment Method|

|J54 | Pressure Monitoring, Conventional Closed Scenarios | 1-channel SPDT | NEMA 1 | Internal Hexagonal Screw (No Scale)|

|J54A | Pressure monitoring, dual output requirement | 2-channel SPDT | NEMA 1 | Hexagonal socket screw (without scale)|

|H54 | Pressure monitoring, requiring intuitive adjustment | 1-channel SPDT | NEMA 1 | Reference dial|

|B54 | Temperature monitoring (probe type), intuitive adjustment | 1-channel SPDT | NEMA 1 | Reference dial|

|E54 | Temperature monitoring (bulb+capillary), intuitive adjustment | 1-channel SPDT | NEMA 1 | Reference dial|

|With the suffix "S" (such as J54S, B54S) | Customized shell scene | 1/2 SPDT | Open | Corresponding adjustment method|

Option key code:

|Option code | Function description | Applicable restrictions|

|0140 | Gold plated contacts (1A 125VAC resistive) | Not suitable for 16008-16009|

|0500 | Narrow dead zone (5A 125/250VAC resistive) | Not applicable to B54, J54A, 16008-16009, etc|

|1530 | External manual reset (15A 125/250/480VAC) | Only applicable to H54, some pressure models, not applicable to open models|

|2000 | High current output (20A 125/250/480VAC) | Not suitable for 16008-16009|

|M501 | Polysulfone pressure connection (1/2 "NPT male x 1/8" NPT female) | Not suitable for pressure and temperature models such as 126-164 and 610-614|

(2) Additional temperature model options

Connection accessories: Provide 1/2 inch NPT union (brass/stainless steel), thermocouple sleeve (such as W191:1/2 inch NPT x 4 inch length, brass);

Scale unit: optional Celsius dial (only supported for some temperature models);

Identification label: Optional stainless steel label (up to 2 lines, 25 characters per line).

Installation and usage precautions

Extreme parameter control:

It is strictly prohibited to exceed the "withstand voltage" and "maximum temperature" limits (even short-term impact), and continuous operation should be within the "adjustable set point range" to avoid frequent switching near the limit value to extend the service life;

The ambient temperature should not exceed the product label range, and electrical connection holes should be sealed in humid environments to prevent water ingress.

Safety design:

Critical safety scenarios (such as personnel/equipment protection) require the configuration of backup switches and the installation of high and low limit protection to prevent loss of control;

The range of the set point should be reasonably selected to avoid unsafe conditions of the system caused by misoperation (such as excessive pressure and temperature).

Maintenance requirements:

Regularly verify the drift of the set point, and immediately check if any display abnormalities or action faults are found;

Do not disassemble or modify the product on your own. If customization is required, please contact the UE manufacturer;

Electrical wiring must comply with local regulations, and wire specifications should refer to the installation manual to avoid overload (the first overload may damage the switch).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands