Intelligent mine production scheduling system

First, the system introduction

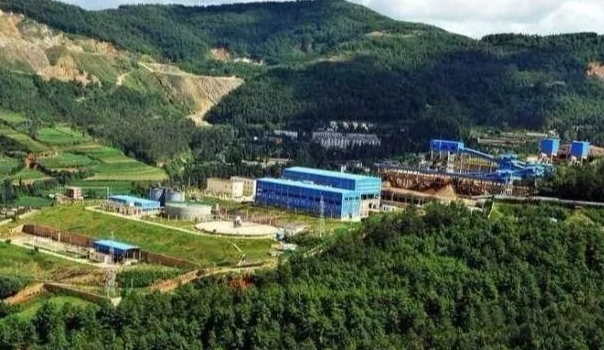

The smart mine production scheduling and control system is built on the basis of digitization, informatization, virtualization, intelligence and integration, and comprehensively considers various factors such as production, management, operation, safety, efficiency, environment and resources. And the use of computer, network, communication, virtual simulation, automatic control and monitoring technology to all kinds of mining information resources for comprehensive, efficient and orderly management of the system, improve the enterprise management mode, so that the operation and management more fair, just, safe, reasonable and efficient. Intelligent production scheduling system is a typical interdisciplinary new field, covering the whole process of production and management in mining enterprises. The system realizes network, digitization, modeling, visualization, integration and scientific management of all links and production factors of mine production, operation and management to achieve a safe, efficient and low-consumption production process.

Ii. Project significance and necessity

(1) Reduce labor intensity in mines and improve work efficiency

Through the intelligent mine production scheduling and control system, the information process involved in the whole mine can be understood, especially the law of information connection and interaction between multiple bodies of the mine system. The original data base and mineral deposit model built by computer can be searched efficiently and conveniently on computer at any time. Use these data to build geological models; The geological model can also be used for mine design, underground survey, production schedule and parameter optimization.

Based on the mining production planning, the digital mine adjusts the planning target and re-prepares the production plan according to the actual ore mining quantity and ore quality data. In view of the uncertain situation such as the change of equipment production capacity and sudden failure in the actual production process, the mining equipment scheduling optimization method is studied. With the support of wireless network, the on-site mining production is monitored and dynamic adjustment suggestions and measures are put forward, so that the mining production can meet the planning requirements and minimize the mining production cost, and the production efficiency and social benefits are improved.

(2) Resolving hidden risks in mines and enhancing safety systems

The purpose of digital mine construction is to maximize the reasonable allocation of various resources, optimize the control and scheduling of various equipment and equipment through the organic integration of various mine information systems, computing technology and industrial control, to achieve scientific mine management and production safety, efficiency, economy and optimization of mineral resource utilization.

Digital mine is a unified understanding and digital representation of the real mine as a whole and its related phenomena, which can effectively use digital ways to monitor and monitor the environment. All kinds of information of production space are collected and various analysis models are established. Processing the collected information, resolving the high risk and high hazard factors in the mining process, preventing possible disasters and accidents, handling major accidents in advance, and eliminating accidents in hidden dangers. Reduce mining risks, reduce labor intensity of workers and ensure the safety of production personnel. Through the intelligent mine production scheduling and control system, the ability of mine safety production management is improved, the level of mine technology management is further improved, technical support is provided for safe production decision-making, and ultimately an intrinsically safe mine based on digitization, information technology and management modernization is realized.

(3) Develop resources rationally and reduce resource waste and environmental pollution

As there are fewer and fewer high-grade mines and easy mining stones, there are more and more low-grade ores and ores with large burial depths, which are more and more difficult to mine and select. Digital mine, on the one hand, can re-delineate the ore body and calculate the reserves, on the other hand, can also provide an effective way to reduce the mining cost. After the intelligent mine production scheduling and control system, industrial indicators can be optimized, according to the requirements of manufacturers of different products for raw materials, through purposeful and planned mining, rich ore and low grade ore in a certain proportion to become commodity ore, but also increase the utilization rate of lean ore. Digital mine is conducive to rational development of resources, full utilization of low and medium grade ores, comprehensive utilization of multi-component mineral resources, and optimization of grade indexes. At the same time, by establishing a mineral model, the quantitative distribution law of each mineral in three-dimensional space is identified, and the favorable ratio of mineral content in selected ores is maintained through fixed-point mining and proportional ore allocation, so as to improve the recovery rate of mineral processing, reduce the amount of mineral processing agents, and reduce resource waste and environmental pollution.

Third, system functions

(1) Real-time monitoring and scheduling

By applying cutting-edge technologies such as GPS/ Beidou positioning technology, 4G wireless communication network and Google Map to the dynamic real-time tracking of open-pit operating equipment, managers can grasp the working location of vehicles and the distribution of vehicles in mining areas in real time. The system can give real-time warning to the working area and speed state of the vehicle, which greatly improves the management level of mining production management.

Based on the optimal scheduling of production vehicles in open pit mines, and using relevant theories such as mining system engineering and queuing theory, the new generation of high-tech technology such as Internet of Things technology and open pit truck shovel scheduling are organically combined to carry out dynamic traffic flow planning for open pit vehicle transportation, and carry out real-time scientific scheduling for open pit truck and excavator, avoiding the phenomenon of vehicles running around randomly and queuing for a long time. By changing the traditional scheduling mode, the operation efficiency of the equipment can be significantly improved by 10%-15%.

(2) Automatic measurement statistics

By combining advanced remote RFID radio frequency identification technology with high-precision positioning equipment and combining automatic identification with vehicle loading track, an automatic measurement algorithm is proposed. Without manual intervention, automatic, fast and accurate measurement of the amount of ore and rock transported by open-pit vehicles is realized, and the measurement error relying on historical track alone is eliminated, and the post of the meter is abolished. The disadvantages of traditional manual measurement of ore and rock transportation are avoided, and the efficiency of open-pit vehicle transportation is greatly improved.

(3) Intelligent identification of loading image

Image acquisition technology is used to collect the loading situation of vehicles in real time, and AI image intelligent recognition algorithm is used to dynamically analyze the full load situation of vehicles' ore or slag, and the load rate is fed back to dispatching managers in real time, and intelligent analysis of vehicle load rate is carried out regularly, providing decision-making basis for optimizing vehicle transportation and achieving fine management of vehicle transportation.

(4) Intelligent analysis of equipment health

Using vehicle data acquisition interface and GPS positioning and tracking technology, real-time acquisition of vehicle running water temperature, fuel consumption, engine running time, battery voltage and other key parameters, the use of operating equipment fault diagnosis technology for timely intelligent analysis and reminder of abnormal situations.

(5) Production vehicles are driverless

The core functions of the underground electric locomotive unmanned operation, automatic ore drawing, track obstacle identification, anti-collision warning and other unmanned systems are realized. It reduces the number of underground operators, improves the working environment of front-line workers, increases the operation time of equipment, improves the level of mine management, and realizes the essential safety.

(6) Vehicle intelligent scheduling analysis

Based on the optimal scheduling of production vehicles in open pit mines, and using relevant theories such as mining system engineering and queuing theory, the new generation of high-tech technology such as Internet of Things technology and open pit truck shovel scheduling are organically combined to carry out dynamic traffic flow planning for open pit vehicle transportation, and carry out real-time scientific scheduling for open pit truck and excavator, avoiding the phenomenon of vehicles running around randomly and queuing for a long time. By changing the traditional scheduling mode, the operation efficiency of the equipment can be significantly improved by 10%-15%.

(7) Intelligent analysis of mining big data

Through the establishment of a central database and other means, the smart mine management resource sharing function has been strengthened, the data update has been timely, centralized, and efficient, and the mining big data intelligent analysis system has been formed to achieve data-based decision-making and information management.

(1) Vehicle running state analysis: The vehicle conducts real-time intelligent analysis through the number of fixed points, parking waiting time, driving speed, shovel card reading, spatial positioning, etc., to obtain the running state;

(2) Analysis of equipment maintenance data: make a reasonable maintenance queue sequence according to the repair categories and times of excavators and trucks, and guide the maintenance department to store spare parts.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands