Small products, big use! This chemical fiber "supporting role" is not a "walk-on"

Lu Shuhui, engineer of Chuanhua Chemical Research and Development Center, said that at present, the market share of domestic DTY oil has reached nearly 90%, but the market share of domestic FDY oil is less than 20%, and the market share of domestic POY oil is less than 10%, and the former spinning oil needed by China's chemical fiber industry still relies heavily on imports.

Especially in the high-performance fiber industry of strategic materials related to national defense, the role of treatment agents, including oil additives and sizing agents, is very important.

"The treatment agent is a molecule that accumulates on the surface of the fiber, like a 'cosmetic' for the fiber." Zheng Guo, professor of Tianjin University of Technology, introduced that the interface treatment technology of high-performance fiber is very important, although the amount of treatment agent used in the production is very small, but the fiber spinning forming, smooth drafting, high temperature treatment, improve the fiber quality and performance are crucial。

At present, the amount of treatment agent required for high-performance fiber in China is about 9,000 tons per year.

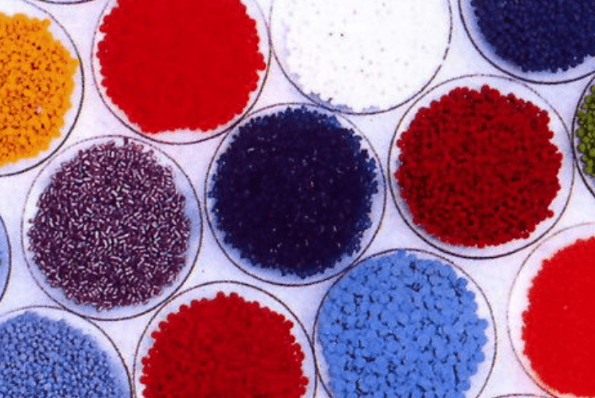

Color masterbatches and functional masterbatches differ in performance

Masterbatch is the core raw material for chemical fiber to achieve the coloring and functional modification of the stock solution.

Chen Xinwei introduced that with the technological progress of dye industry, electronic color matching technology and masterbatch carrier, China's fiber masterbatch industry has achieved rapid development, the total demand of about 200,000 tons per year, has black masterbatch, dull masterbatch, color masterbatch and functional masterbatch, as well as outdoor supplies, automotive interior with high sun resistance masterbatch and other rich and diverse products. Among them, the masterbatch of automobile interior fabric breaks the foreign monopoly and realizes the localization replacement; Some color masterbatches and functional masterbatches meet the requirements of military fiber production and application.

By category, China's color masterbatch industry has developed rapidly in recent years, and the production enterprises are mainly distributed in Jiangsu, Zhejiang, Fujian and Guangdong.

Suzhou Baolidi Material Technology Co., Ltd. is a leading enterprise in the masterbatch industry in China, specializing in liquid coloring and functional modification of chemical fiber masterbatches, with an annual capacity of 60,000 tons of masterbatches, mainly covering polyester and nylon 6 two series and 10 series products.

Polaroid's products are mainly black and white and color masterbatches. Xie Wei, director of research and development of the company, said that the stock solution coloring technology can reduce the post-dyeing and finishing process, reduce the emission of waste gas and wastewater, greatly save the "post-pollution" phenomenon of the production water of textile enterprises and chemical dyes, green environmental protection, and the market demand has increased year by year in recent years. In particular, it will play a positive role in the process of implementing the goal of "carbon peak" and "carbon neutrality" in the country.

Due to the trend of green development, the market demand of color masterbatch has increased rapidly in recent years.

"The new Fengming Group mainly uses a lot of black masterbatch." Cui Li introduced that the company's annual consumption of black masterbatch is tens of thousands of tons, some of which are produced by themselves and the other part is purchased externally.

The development of functional masterbatch in our country has also made a certain breakthrough. For example, Polaridi's functional masterbatches include antibacterial, flame retardant, anti-static, luminous and other types, and in the past two years, it has also developed light-colored heating masterbatches, anti-counterfeiting tracking masterbatches, aerogel masterbatches and other innovative products.

Xie Wei introduced that the company's light-colored heating masterbatch has a good light-heat conversion efficiency, which can convert light energy into heat energy, and has been used in some mountaineering clothing and winter textiles; The anti-counterfeiting tracking masterbatch is used in the recycled fiber industry and can be traced to the manufacturer of the recycled fiber.

However, there is still a big gap between China's functional masterbatch and foreign countries, and the functional research of masterbatch mainly focuses on flame retardant masterbatch, antistatic masterbatch, toughening masterbatch and other aspects, and the functionality is still not rich and diversified.Ji Peng, associate researcher of Textile Science and Technology Innovation Center of Donghua University, pointed out that the design, preparation and application of fiber masterbatch involve complex technology, strict quality control, long research and development cycle, and high preparation cost, which has always been the high point of the international fiber market competition.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands