The influence and solution of grid-connected photovoltaic power generation on power quality

1 Basic Principles

Photovoltaic power generation uses the photovoltaic effect present on the surface of the semiconductor to send a direct current through the light at both ends of the semiconductor material. When the sun shines on the semiconductor P-N node, a new electron-hole pair is formed, and after the photon excits the electron from the covalent bond, the electron flows to the N region and the hole flows to the P region, resulting in a potential difference between the two ends of the semiconductor. Once the circuit at both ends of the PN junction is connected, a current will be formed, flowing from the P zone to the N zone through the external circuit, and the electrical power will be output to the load.

2. Structure and classification of grid-connected photovoltaic power generation

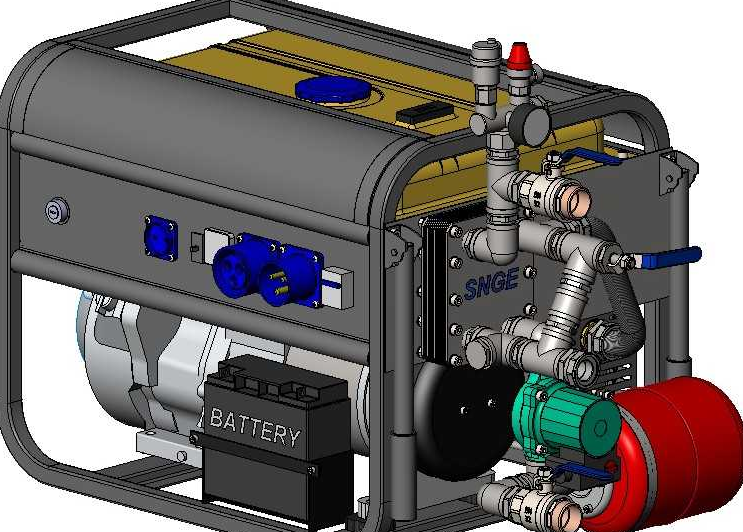

Grid-connected photovoltaic power generation system is mainly composed of solar panel (module), high power tracking (MPPT) controller, DC-AC inverter several parts, using insulated gate bipolar transistor (IG-BT) as the switching element of photovoltaic inverter. The DC output of the solar cell goes through the DC-DC converter to increase the voltage level, and then the DC is converted into alternating current with the voltage amplitude, frequency and phase of the power grid through the DC-AC inverter, so as to realize the integration into the power grid or power supply to the AC load. The structure of photovoltaic power generation system is shown in Figure 1.

According to the grid-connected operation mode, the photovoltaic power generation system can be divided into three forms: countercurrent grid-connected, no countercurrent grid-connected and switching grid-connected. Grid-connected photovoltaic power generation system is directly connected to the power grid, does not require energy storage batteries, saves the floor area, greatly reduces the configuration cost, and the load power deficit is supplemented by the power grid. Therefore, grid-connected photovoltaic power generation system is the main development direction of solar power generation, and it is also a potential new energy power generation method at this stage.

3. The influence of grid-connected photovoltaic power generation on power quality of the grid

Photovoltaic power generation as a new energy generation, lighting, temperature and other external conditions of randomness, volatility, intermittent changes are the main factors of photovoltaic power generation impact on the grid. Wang Jinjing 13-77+443+09-92, among which DC-AC inverter is one of the main devices of grid-connected photovoltaic power generation system, the quality of photovoltaic inverter determines whether the power quality of photovoltaic power generation can meet the grid-connected requirements to a certain extent. When photovoltaic power generation is connected to the grid, problems such as harmonics, voltage fluctuations and flickers, DC injection, and island effect will occur, which will reduce the power quality of the grid and cause adverse effects on the grid. In serious cases, it will disrupt the safe and stable operation of the power supply system and photovoltaic power generation equipment itself.

3.1 DC Injection problem

Another key problem to be solved in grid-connected photovoltaic power generation system is DC injection. Dc injection affects the power quality of the grid, and also brings adverse effects to other equipment in the grid. IEEEStd929-2000 and IEEEStd547-2000 clearly stipulate that the DC current component injected into the grid by the grid-connected power generation device cannot exceed 0.5% of the rated current of the device. The main causes of DC injection are as follows: 1) the dispersion of power electronic devices and the inconsistency and asymmetry of drive circuits; 2) Zero drift and nonlinearity of measuring devices in high-power controller; 3) Asymmetry of line impedance of each switching device, influence of parasitic parameters and parasitic electromagnetic fields, etc.

At present, the main methods to suppress DC injection include: 1) detection compensation method; 2) Optimize and design the grid-connected structure of the inverter; 3) Capacitor straight separation; 4) Virtual capacitance method; 5) Device isolation transformer.

3.4 Impact of island effect

The islanding effect refers to the phenomenon that the grid power supply is interrupted due to human factors or natural factors, but each grid-connected photovoltaic power generation system fails to detect the power grid blackout state in time, so that the photovoltaic power generation system and the connected load still operate independently. With the continuous expansion of the access penetration rate of grid-connected photovoltaic power generation, the probability of island effect is gradually increasing.

The formation of island effect has adverse effects on the power quality of the entire distribution network, mainly including:

1) When the distribution network is switched to the island mode, only relying on the photovoltaic power generation system to supply electricity, if the power supply system capacity is too small or no energy storage device is installed, it is possible to cause voltage instability and flicker problems in the user load.

2) After the island effect occurs in the photovoltaic power generation system, if the original power supply mode is single-phase power supply mode, it may cause the problem of three-phase load asymmetry in the distribution network, and then reduce the overall quality of electricity consumption of other users.

3) In the process of power supply recovery, inrush current will be generated due to the asynchronism between voltage phases, which may cause the grid waveform to drop instantaneously.

4) In the location where the island effect occurs, its voltage and frequency fluctuate greatly, which reduces the power quality, and the voltage and frequency in the island are not controlled by the power grid, which may cause damage to the system electrical equipment and reclosing failures, and may also cause personal safety hazards to the power grid maintenance personnel. Ankerui manufacturer Wang Jinjing 13-77+443+09-92

For the impact of island effect, there are mainly the following solutions:

Optimize the island detection method of grid-connected photovoltaic power generation system, analyze the influence of photovoltaic power generation on the size, direction and distribution of fault current in distribution network, and improve the selection technology of load cutting speed and island division under fault conditions.

2) Improve the reliability of island detection technology, configure fast and effective anti-island protection function, accurately judge the island status under abnormal circumstances and quickly and effectively interrupt the grid connection.

Aiming at the power quality problem after photovoltaic access, the effective methods of suppressing harmonics are put forward: 1) Starting from the source of harmonic generation, the harmonic source is reformed to reduce harmonic injection. Wang Jinjing 13-77+443+09-92, 2) Device active or passive filter to absorb some specific number of harmonic current. 3) Install additional harmonic compensation devices.

3.2 Voltage fluctuation and flicker

In the traditional distribution network, the change of active power and reactive power with time will cause the system voltage fluctuation. For photovoltaic power generation, the change of active power of photovoltaic power generation system is the main factor that causes voltage fluctuation and flicker of access point. Wang Jinjing 13-77+443+09-92, the high power point of photovoltaic panels, the core components of photovoltaic power generation system, is closely related to radiation intensity, weather, season, temperature and other factors, and the random changes of these natural factors cause the output power to change greatly, resulting in frequent changes in the load power within a certain range. It causes the load terminal voltage fluctuation and flicker of grid-connected users.

At present, the solutions to the photovoltaic voltage fluctuation and flicker problems are as follows: 1) Optimize the control strategy of photovoltaic grid-connected inverters to improve the voltage stability; 2) Increase the short circuit capacity of the substation bus; 3) When the capacity of the photovoltaic power station is determined, its power factor is increased to increase the total active power, thereby reducing the amount of reactive power change and meeting the limit requirements of voltage fluctuations.

3.3 Harmonic Effects

Photovoltaic power generation is to convert solar energy into direct current through photovoltaic modules, and then through the grid-connected inverter to convert direct current into alternating current to achieve grid-connected. In the photovoltaic power generation system, the inverter is the main equipment to produce harmonics. The large number of applications of power electronic components in grid-connected inverters has improved the information and intelligent processing of the system, but it also increases a large number of nonlinear loads, causing waveform distortion and bringing a large number of harmonics to the system. The delay of the switching speed of the inverter will also affect the output of the overall dynamic performance within the power system, resulting in a small range of harmonics. If the weather (irradiance, temperature) changes greatly, the fluctuation range of harmonics will also become larger. Although the output current harmonics of a single grid-connected inverter are small, the output current harmonics of multiple grid-connected inverters will be superimposed after they are connected in parallel, resulting in the phenomenon of output current harmonics exceeding the standard. In addition, the parallel connection of inverters is easy to produce parallel resonance, which leads to the coupling resonance phenomenon, resulting in the expansion of specific harmonic current and the problem of excessive harmonic content of grid-connected current.

4 Ankerui Solutions

4.1 Online monitoring of power quality

The APView500 power quality online monitoring device adopts a high-performance multi-core platform and embedded operating system, and measures the power quality indicators according to the measurement methods specified in IEC61000-4-30 "Test and Measurement Technology - Power Quality Measurement Methods". It integrates harmonic analysis, waveform sampling, voltage dip/rise/interrupt, flicker monitoring, voltage unbalance monitoring, event recording, measurement control and other functions. Wang Jinjing 13-77+443+09-92, the device has reached IEC61000-4-30 Class A standard in all aspects of power quality index parameter measurement method standardization and index parameter measurement accuracy, clock synchronization, event marking function, etc. It can meet the requirements of power quality monitoring of 110kV and below power supply systems.

4.2 Anti-island protection devices

When the anti-island protection device detects that there are abnormal data such as reverse power, frequency mutation, etc., that is, when the island phenomenon occurs, the device can cooperate with the circuit breaker to quickly cut off the node, so that the station and the power grid side are quickly separated, and ensure the life safety of the entire power station and related maintenance personnel.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands