Downstream demand recovery, chemical fiber industry ushered in a cycle reversal

After the downstream demand picked up, the domestic loom operating rate increased significantly, and the textile and clothing trading volume continued to improve. In the first quarter of 2020, under the impact of the epidemic, domestic enterprises stopped production, and the downstream loom operating rate of polyester filament was only 7%, a record low, and the trading volume of the textile city fell to 1.16 million meters in the same period, a decrease of 65%. In the second quarter, the domestic epidemic prevention and control was effective, and enterprises gradually resumed work and production, while the deterioration of the foreign epidemic made the demand for protective materials break out, at the same time, affected by the supply limitation of the epidemic abroad, a large number of orders were transferred to the domestic, the domestic loom operating rate has increased rapidly since the second quarter, and the volume of textile city has rebounded significantly. Spinning and weaving enterprises are expected to resume work better than the same period in previous years, and the tight container problems that continued to restrict downstream and terminal exports in the early stage began to improve from the end of January 2021, providing a foundation for the execution of foreign trade orders in the later stage, and the sustained growth of the demand side has been strongly guaranteed.

Since the second quarter of 2020, retail sales of textile and clothing have rebounded rapidly year-on-year. In terms of domestic downstream textile and garment demand, the retail situation in the first quarter of 2020 was seriously affected by the epidemic, with a cumulative average decline of 30.7% year-on-year, downstream demand gradually recovered in the second and third quarters, and demand increased significantly in the fourth quarter. In 2020, the cumulative retail sales of domestic clothing, shoes, hats and needles, and textile products rebounded from -30.9% in February to -6.6% in December.

Industry prosperity recovery, chemical fiber industry valuation is expected to gradually repair. In the first quarter of 2020, the valuation of the chemical fiber industry is still at a historical low, with the gradual recovery of downstream demand for chemical fiber in the second quarter, the industry boom is picking up, the PPI of the chemical fiber manufacturing industry has improved significantly year-on-year and quarter-on-quarter, and the industrial added value of the chemical fiber manufacturing industry has shown a growth trend. Under the background of high certainty of performance growth in the past 21 years, the market attention of the chemical fiber industry has increased, and the industry valuation has entered the continuous repair channel.

picture

2, polyester filament demand bottomed out and rebounded, and the industry ushered in a turning point

2.1. Basic introduction of polyester filament

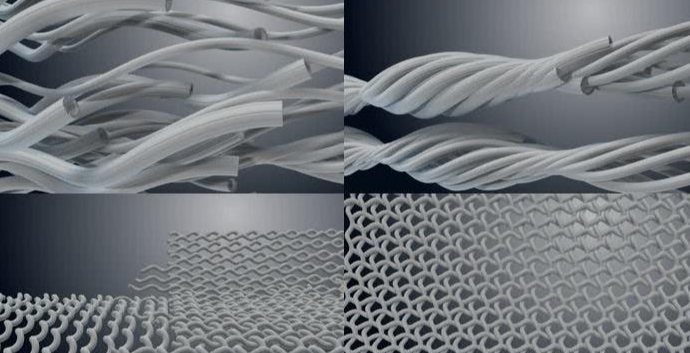

Polyester filament is made of polyester (namely polyethylene terephthalate, referred to as PET) by spinning and finishing the length of more than kilometers of fiber. Polyester, commonly known as "polyester", is made from refined terephthalic acid (PTA) or dimethyl terephthalate (DMT) and ethylene glycol (MEG) as raw materials by esterification or transesterification and polycondensation. Polyester filament has the advantages of high strength, good crease recovery, good wear resistance, and not easy to stain, and is widely used in various clothing and decorative materials.

Polyester filament is located in the middle and lower reaches of the entire industrial chain. Upstream for the petrochemical industry, the main production of PX, ethylene, naphtha and other chemical products; The middle reaches is the chemical fiber manufacturing industry, mainly producing PTA, MEG, PET, polyester film, polyester fiber, polyester chip, etc. Downstream mainly related to polyester filament and staple fiber and its spinning clothing, automotive applications. According to the difference of production process and performance, polyester filament can be divided into three categories: primary silk, stretched silk and deformed silk. Primary silk mainly includes POY (pre-oriented silk); The drawing filament mainly includes FDY (full drawing deformed filament); The textured silk mainly includes DTY (stretched textured silk) and other products, which are mainly used in the civil textile and textile garment industry.

The polyester filament industry has developed rapidly and has a variety of production processes. According to the spinning speed, polyester filament can be divided into conventional spinning process, medium-speed spinning process and high-speed spinning process. According to polyester raw materials can be divided into melt direct spinning and slice spinning; According to the process flow, it can be divided into three steps, two steps and one step. With the development of China's polyester filament industry, the small production capacity has been gradually eliminated, the production scale of the filament device has been upgraded, the leading enterprises in the industry have a significant advantage, and China's polyester filament has also achieved effective results in the production process development.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands