China's large engineering ship technology towards a high level of self-reliance

Because major engineering equipment is placed on a large engineering ship at sea, the construction equipment and the hull connection may be fixed connections, and there may be motion pairs (movable connections where two components are in direct contact and can produce relative motion). In addition to the variable operating load transmitted to the joint by the operating equipment, the wind and wave current load and the ship's positioning load are also transmitted to the joint by the hull, resulting in a very complex and changeable state of the joint force, which may cause various forms of damage. In addition, the alternating load generated by large working equipment during construction (the load effect of the size and direction of the mechanical parts in the working process is periodically changed with time) or repeated impact will be transmitted to the hull through the connecting part, which will produce local or entire hull vibration, affect the working efficiency, and even cause resonance, resulting in structural damage. The design of joint parts is often a difficult point in the structural design of large offshore engineering ships, and there are no ready-made norms and standards, so it is necessary to study new engineering calculation methods, establish new design standards, and create new structural forms.

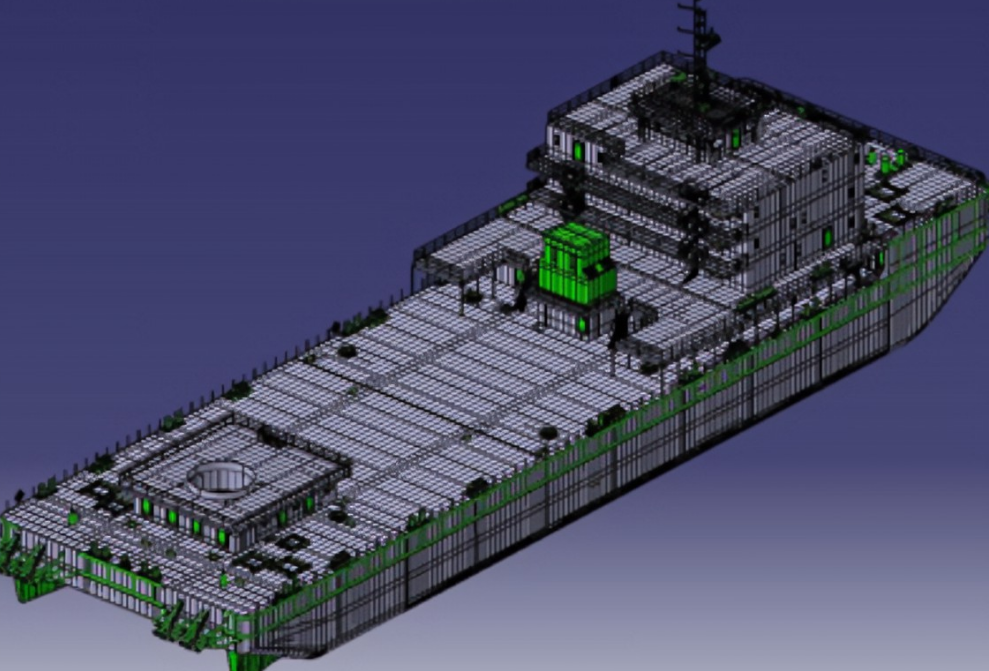

After large construction equipment is placed on a large engineering ship at sea, the overall design of the ship will change significantly compared to the transport ship. Large offshore engineering ships have special ship type, many equipments, high power density and complex working conditions, so the overall design method of transport ships cannot be followed. The main scale demonstration based on volume and speed is changed to the determination of main elements based on operational capability. The overall layout design is changed to the layout design based on the work flow according to the various layout status requirements of cargo loading and specifications; The power configuration based on navigation requirements is changed to one based on balance and high operational capability. The design process based on the statistical law of the real ship is changed to the design process based on non-standard operation equipment. These changes greatly increase the difficulty and risk of large offshore engineering ship design.

Take aim at the Four Modernizations

Future development achievements are worth looking forward to

In order to actively respond to the national strategy of becoming a maritime power and strengthen the construction capacity of China's far-reaching Marine resources development and major projects, China's offshore large engineering vessels are expected to make greater achievements in realizing the "Four modernizations", namely large-scale, intelligent, multi-functional main body and modular construction equipment.

The working waters of China's offshore engineering ships are rapidly expanding from the coastal and offshore waters to the deep sea, the deep sea Marine environment is harsh, "small boats can not withstand the wind and waves, the giant ship can withstand the waves", the large size of offshore engineering ships is an inevitable trend. The upsizing of ships improves the ability to withstand wind and waves, increases the meteorological window period of operations, and also provides a more effective platform for the improvement of operational capabilities of operating equipment. In particular, the upsizing of engineering ships provides mother ships with better guarantee functions for the development and use of deep-sea operating systems. Major needs such as deepwater oil and gas development, deepwater metal mining, deepwater pipe laying, deepwater dredging and construction of major deepwater infrastructure will promote the rapid development of deepwater operating systems, and the improvement of deepwater operating capabilities will be synchronized with the large-scale offshore engineering vessels.

In some types of large offshore engineering ships independently developed in China, the level of automation of the operation has been quite high, and the operation process can be completed according to the designed procedures and steps without manual intervention or minimal intervention, but there is still a long way to go to realize intelligence on the basis of automation. There are still a lot of in-depth work to be done in the aspects of information sufficiency, knowledge data, self-learning function, etc. Using the Internet of Things technology to realize the intelligent operation of large offshore engineering ships will not only greatly improve the efficiency of the operation, but also make the large offshore engineering ships have more functions and stronger environmental adaptability.

Large offshore engineering ships are generally expensive, single-function ships often have fewer tasks, not only idle is inevitable, and even when a major project is completed, the corresponding engineering ship is no longer used, and the construction cost of a ship is all included in a project. The actual situation is that many large offshore engineering ships with different functions have very similar requirements on hull size, layout status and power equipment configuration. If various functions can be taken into account in the design of engineering ships, and positions and interfaces can be reserved, it is possible to make the hull of the engineering ship owner a platform that can meet various functions and achieve multi-functional engineering ships. While the main hull has become a multi-functional platform, it also requires the modularization of construction equipment to realize the standardization of the connection between construction equipment modules and the hull, and ultimately improve the utilization rate and economy of large offshore engineering ships.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands