China's large engineering ship technology towards a high level of self-reliance

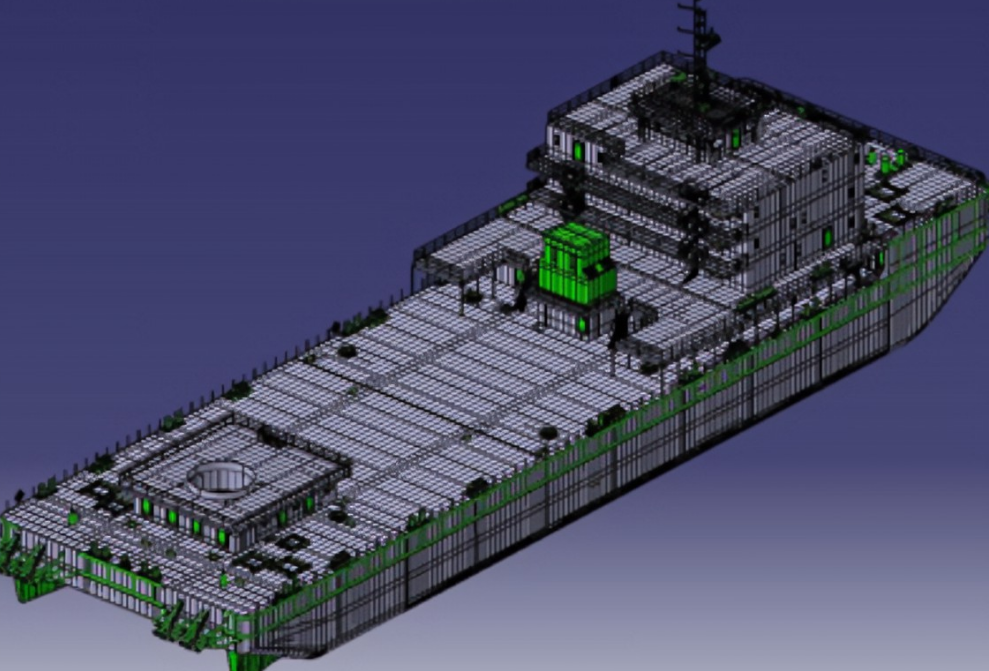

Skywhale is a large cutter suction dredger designed by Tan Jiahua. Its success indicates that the design, construction and use technology of China's large cutter suction dredger at sea have reached the international advanced level. Shanghai Jiao Tong University

With the continuous expansion of human ability to rationally utilize Marine resources, the development of Marine science and technology has become one of the major strategies for maritime countries to improve their comprehensive national strength. The particularity of the Marine environment determines that all Marine activities, such as exploring and understanding the ocean, developing and utilizing Marine resources, protecting the Marine environment, and maintaining national Marine security, must rely on corresponding Marine equipment and technology. It can be said that whoever has advanced equipment and technology will have an advantage in future Marine development. Large offshore engineering ship is a special ship with high investment and high technology that can complete various construction tasks above and below water. It is a major core equipment to achieve the strategic goal of national maritime power, and its design and manufacturing technology is the core key technology of the country.

Due to the numerous fields involved in the research and development of China's large offshore engineering ships, they have been developed independently for a long time, with dispersed forces and low information and equipment sharing rate. As a long-term research and designer of large offshore engineering ships, the author deeply feels that the research, development and use of China's large offshore engineering ships are in a historical turning point and rapid development period, so we must take a high level and high quality development path, improve the original innovation ability, concentrate on overcoming the "bottleneck" problem, and carry out the "land-sea overall planning" of large offshore engineering ships. To realize the joint development of large-scale offshore projects and upstream and downstream industries, and make greater contributions to the construction of a maritime power.

Struggle to catch up

Some technologies have reached the international leading level

Due to the complete industrial system of European countries and the strong research and development capabilities of large offshore engineering ships, many new types of large offshore engineering ships were first developed in Europe. Large European shipbuilding groups have strong design, construction and supporting strength, flexible and diversified management methods, and the relevant construction market is still dominated by European shipyards. China started late in the field of large offshore engineering ships, and still lags behind developed countries in Europe and the United States in terms of equipment core technology, but since the reform and opening up, especially in the past 20 years, China's industrial system has gradually improved, the shipbuilding industry has developed rapidly, and great progress has been made in the field of large offshore dredgers, large cranes and wind power installation ships, and some technologies have reached the international leading level.

In terms of large offshore dredgers, China has realized domestic design and manufacturing in the field of main types of cutter suction dredgers and rake suction dredgers, and has got rid of the dependence on foreign countries. Especially since the beginning of the 21st century, due to the strategic needs of coastal port and waterway dredging, offshore major infrastructure and industrial base construction, and far sea islands and reefs construction, a large number of high-tech and high value-added dredgers with independent intellectual property rights have been launched. In particular, the development of large cutter suction dredgers at sea has broken through core technologies such as offshore positioning, rock excavation, long-distance transportation and complex system integration, and has designed and built a number of large cutter suction dredgers at sea. The working sea area extends from coastal and offshore to far sea, and the digging soil has expanded from silt and hard sand to hard rocks. The operation capacity of a single ship has been increased from 2,500 cubic meters per hour to 6,500 cubic meters, forming a series of products, and driving the rapid development of equipment technology and industry in the dredging industry. In the past 20 years, China's annual dredging capacity has increased from 300 million cubic meters to 1.7 billion cubic meters, accounting for about 40 percent of the world dredging market. China's large dredgers have realized the leapfrog development from being blocked to export control, not only meeting domestic demand, but also playing an important role in the construction of ports and waterways in the "Belt and Road".

In terms of large cranes, according to different operational needs, foreign countries have developed a variety of large offshore cranes such as single-hull, multi-hull and semi-submersible vessels, which are used for the installation and removal of jacket platforms, the lifting installation of Bridges and tunnels, the laying of submarine pipelines, maritime salvage and rescue. At present, the world's largest lifting capacity of semi-submersible crane capacity of 20,000 tons. Compared with foreign countries, the domestic large crane market is in a stage of rapid development. With the implementation of the national energy strategy, the exploration and exploitation of deep-sea oil and gas fields have entered the concrete implementation stage, and the demand for large crane ships is quite large. Domestic research institutions, design units, and ship manufacturing enterprises have made breakthroughs in some key technologies such as improving the ship's ability to withstand wind and waves, ship positioning and shifting technology, the impact of ship motion on crane design, and crane control and operation technology through the combination of independent research and development and introduction, digestion and absorption in the past 20 years. Gradually formed a number of products with independent intellectual property rights, so that the lifting capacity of China's large offshore crane ships from hundreds of tons to 10,000 tons. China has independently designed and manufactured the world's largest single-hull crane, with a lifting capacity of 12,000 tons. At present, the overall situation is that the number of large cranes in China is large, the variety is single, and the lifting capacity is still small.

Wind power installation ship is a new kind of offshore engineering ship, mainly used for the transportation and hoisting of offshore wind power equipment. It integrates various functions such as component transportation, offshore operation, lifting and daily supply, and can independently complete the above-mentioned transportation and installation operations. Since Denmark built the world's first offshore wind farm in 1991, countries around the world have begun to build offshore wind power projects. Wind power installation equipment has experienced three generations of development: the first generation by the existing crane and transport barge combined operation; The second generation is a barge or platform with self-elevating function, but does not have self-propelled capability; The third generation of special wind power installation ship with self-propelled, self-lifting and lifting functions. At present, the wind power installation ships of foreign professional offshore wind power installation companies belong to the third generation, which are used for wind turbine installation, maintenance and other offshore operations. The "Seajacks Scylla" delivered by Samsung Heavy Industries in 2016 is currently a more advanced wind power installation ship, equipped with a 1,500 ton crane, a speed of more than 13 knots, and can install fan components in wind fields with water depths of more than 65 meters. At present, there are 14 third-generation wind power installation ships abroad, with a lifting capacity of more than 800 tons. Since 2011, relevant domestic design and construction enterprises have independently researched and developed the second and third generation wind power installation ships. At present, China has made great progress in design and construction technology, and the supporting capacity of special equipment has been greatly enhanced. A number of wind power installation ships have been independently designed and built, with a maximum lifting capacity of 2500 tons. However, there are fewer third-generation ships with rack and pinion lifting and self-propelled capability.

Deep blue

Common technological breakthroughs are urgently needed

Large offshore engineering ships are also known as offshore construction equipment, or more precisely, major engineering equipment floating on the sea. Due to the combination of hull and construction equipment and the extension of working waters to the deep sea, higher requirements are put forward for the survivability and working ability of large offshore engineering ships.

For construction equipment, because it is installed on the ship, it is affected by the movement of the ship. The high frequency movement of the ship on the wave, such as rolling, pitching and swinging motion, will produce a large additional load on the construction equipment, will produce forced vibration, so that the safety of the operation is threatened, or even can not work. Equipment that can operate safely and efficiently on land, applied to large engineering ships at sea, must consider the impact of additional loads when designing, and become non-standard equipment that must be specially designed.

The low-frequency motion of ship such as rolling, pitching and yawing and the increase of water depth will have a great influence on the ship's operation positioning and positioning. For large engineering ships operating in the deep sea, setting up reliable positioning, positioning and shifting systems has become an indispensable major technical measure, especially the dynamic positioning system, which can maintain a certain ship position, heading or make the ship move according to the predetermined trajectory by using its own propulsion system. Its position control accuracy is high, its flexibility is good, and the cost does not increase with the increase of the water depth. It has had a significant impact on promoting the progress of large engineering ships at sea. The dynamic positioning system is usually composed of four subsystems: environment and position reference system, propulsion system, power system and control system. The design and manufacture technology of dynamic positioning system has become the core technology in the design and manufacture of large offshore engineering ships.

For large offshore engineering ships, due to the improvement of operational capacity, especially the wide application of dynamic positioning system, the power supply capacity of large engineering ships is much larger than that of transport ships of the same scale, and even reaches more than 3 times. In the past 20 years, due to the mature development of AC frequency converter, electric drive has been widely used in large offshore engineering ships. Therefore, it has become an inevitable trend to build high-power power stations and carry out integrated energy management on large offshore engineering ships. In large engineering ships at sea, the dynamic positioning system and the automatic control of various operations involve the cooperation and coordination of multiple subsystems and equipment, involving the sharing and transmission of state parameters, and including the collection of external information and the necessary judgment and calculation, all of which can only be completed by computer automated network system. It has become one of the core technologies in the design of large offshore engineering ships to make comprehensive management of high-power stations and optimize the energy allocation of large offshore engineering ships under multiple working conditions by using computer network system.

Because major engineering equipment is placed on a large engineering ship at sea, the construction equipment and the hull connection may be fixed connections, and there may be motion pairs (movable connections where two components are in direct contact and can produce relative motion). In addition to the variable operating load transmitted to the joint by the operating equipment, the wind and wave current load and the ship's positioning load are also transmitted to the joint by the hull, resulting in a very complex and changeable state of the joint force, which may cause various forms of damage. In addition, the alternating load generated by large working equipment during construction (the load effect of the size and direction of the mechanical parts in the working process is periodically changed with time) or repeated impact will be transmitted to the hull through the connecting part, which will produce local or entire hull vibration, affect the working efficiency, and even cause resonance, resulting in structural damage. The design of joint parts is often a difficult point in the structural design of large offshore engineering ships, and there are no ready-made norms and standards, so it is necessary to study new engineering calculation methods, establish new design standards, and create new structural forms.

After large construction equipment is placed on a large engineering ship at sea, the overall design of the ship will change significantly compared to the transport ship. Large offshore engineering ships have special ship type, many equipments, high power density and complex working conditions, so the overall design method of transport ships cannot be followed. The main scale demonstration based on volume and speed is changed to the determination of main elements based on operational capability. The overall layout design is changed to the layout design based on the work flow according to the various layout status requirements of cargo loading and specifications; The power configuration based on navigation requirements is changed to one based on balance and high operational capability. The design process based on the statistical law of the real ship is changed to the design process based on non-standard operation equipment. These changes greatly increase the difficulty and risk of large offshore engineering ship design.

Take aim at the Four Modernizations

Future development achievements are worth looking forward to

In order to actively respond to the national strategy of becoming a maritime power and strengthen the construction capacity of China's far-reaching Marine resources development and major projects, China's offshore large engineering vessels are expected to make greater achievements in realizing the "Four modernizations", namely large-scale, intelligent, multi-functional main body and modular construction equipment.

The working waters of China's offshore engineering ships are rapidly expanding from the coastal and offshore waters to the deep sea, the deep sea Marine environment is harsh, "small boats can not withstand the wind and waves, the giant ship can withstand the waves", the large size of offshore engineering ships is an inevitable trend. The upsizing of ships improves the ability to withstand wind and waves, increases the meteorological window period of operations, and also provides a more effective platform for the improvement of operational capabilities of operating equipment. In particular, the upsizing of engineering ships provides mother ships with better guarantee functions for the development and use of deep-sea operating systems. Major needs such as deepwater oil and gas development, deepwater metal mining, deepwater pipe laying, deepwater dredging and construction of major deepwater infrastructure will promote the rapid development of deepwater operating systems, and the improvement of deepwater operating capabilities will be synchronized with the large-scale offshore engineering vessels.

In some types of large offshore engineering ships independently developed in China, the level of automation of the operation has been quite high, and the operation process can be completed according to the designed procedures and steps without manual intervention or minimal intervention, but there is still a long way to go to realize intelligence on the basis of automation. There are still a lot of in-depth work to be done in the aspects of information sufficiency, knowledge data, self-learning function, etc. Using the Internet of Things technology to realize the intelligent operation of large offshore engineering ships will not only greatly improve the efficiency of the operation, but also make the large offshore engineering ships have more functions and stronger environmental adaptability.

Large offshore engineering ships are generally expensive, single-function ships often have fewer tasks, not only idle is inevitable, and even when a major project is completed, the corresponding engineering ship is no longer used, and the construction cost of a ship is all included in a project. The actual situation is that many large offshore engineering ships with different functions have very similar requirements on hull size, layout status and power equipment configuration. If various functions can be taken into account in the design of engineering ships, and positions and interfaces can be reserved, it is possible to make the hull of the engineering ship owner a platform that can meet various functions and achieve multi-functional engineering ships. While the main hull has become a multi-functional platform, it also requires the modularization of construction equipment to realize the standardization of the connection between construction equipment modules and the hull, and ultimately improve the utilization rate and economy of large offshore engineering ships.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands