Export high-end ship praises "Made in China"

High-tech, difficult, high value-added ship manufacturing brings new opportunities to help Guangzhou become a domestic high-end ship offshore equipment research and development innovation center

From conventional bulk carriers, container ships and oil tankers, to "high-tech", "difficult" and "high value-added" gas carriers, senior passenger rolling vessels, carbon fiber high-speed passenger ships, with the changes in the international market and the stimulation of the domestic consumer market, China's shipbuilding industry has ushered in new development opportunities.

Guangdong Province has listed the shipbuilding industry as one of the five key industries in the development of advanced manufacturing industry in the province, and proposed to build the Pearl River estuary area, which is dominated by Guangzhou, into one of the three major shipbuilding bases in China. In the first quarter of this year, China's high-tech ship research and development and construction have made new breakthroughs, batch to undertake a series of high-end ships, Guangdong shipbuilding industry's three major indicators "shipbuilding completion", "new ship orders" and "hand-held ship orders" have risen year-on-year.

In addition, the repair load ratio (revised gross tons/deadweight tons), which reflects the technical level of new ship orders, reached 0.444, much higher than 0.392 in the same period last year. Chen Jianrong, secretary general of Guangdong Shipbuilding Industry Association, told reporters that this means that China's structural transformation has achieved remarkable results, and the proportion of high-end ship types has increased, and China is moving forward from a shipbuilding country to a shipbuilding power. Recently, the reporter also conducted an investigation and interview on the shipbuilding industry in Guangzhou.

Passenger ship replacement:

Take aim at carbon fiber technology

On Xiaohu Island in Nansha, Guangzhou, two technical workers are carefully "sticking" a layer of carbon fiber fabric in the "carbon fiber shipyard" workshop of Guangdong Zhongwei Composite Materials Co., LTD., a subsidiary of Pearl River Shipping. Unlike the huge "bang bang" sound in the traditional shipbuilding workshop, this workshop is unusually quiet, and occasionally comes the sound of an air nail gun.

At the dock of the shipyard, two passenger ships have been built "Haizhu Bay" and "Haizhu Lake", soon, they will be the first phase of Pazhou Hong Kong Macao Passenger Terminal put into use carbon fiber high-speed passenger ships, will be in the way of sea-to-sky transport, about 120 minutes from Pazhou to the Hong Kong International Airport direct. Carbon fiber high-speed passenger ship using water jet propulsion, the speed of more than 37 knots, much faster than the average passenger ship's speed of about 25 knots.

"Haizhu Lake" carbon fiber high-speed passenger ship

It is understood that the "Haizhu Bay" and "Haizhu Lake" carbon fiber high-speed passenger ship is one of the "achievements" of Guangdong Zhongwei Composite Materials Co., LTD. The company's director and general manager Huang Chuanfei told reporters that as early as 2015, in response to the requirements of low-carbon environmental protection, the Pearl River shipping superior unit Guangdong Port and Shipping Group Co., Ltd. will layout green ship manufacturing and shipping in advance, during the "13th Five-Year Plan" period, Guangdong Port and Shipping Group Co., Ltd. to promote the transformation and upgrading of the shipbuilding industry, With the opportunity of upgrading high-speed passenger ships owned by the relevant enterprises under Pearl River Shipping, on the one hand, we are looking for high-speed passenger ships that are faster, more economical, more comfortable and more environmentally friendly, so as to cope with the impact of various aspects of the high-speed passenger ship market in the Greater Bay Area; On the other hand, after a variety of global investigation and research, Pearl River Shipping decided to take the lead in introducing carbon fiber ship construction technology and process, acquired the shares of Norway's well-known carbon fiber ship construction BrAa company and set up a joint venture Guangdong Zhongwei Composite Materials Co., LTD.

Introduce advanced materials to overcome technical problems

In 2013, the "Notice of The State Council on Printing and distributing the Implementation Plan for Accelerating Structural Adjustment and Promoting Transformation and Upgrading of the Shipbuilding Industry (2013-2015)" issued by The State Council mentioned that "support qualified enterprises to set up R&D centers overseas through self-establishment, mergers and acquisitions, joint ventures, cooperation and other ways to support overseas industrial restructuring." Master advanced technologies in the fields of Marine engineering equipment, high-tech ships and supporting equipment."

Huang blooming introduced that when the company determined the direction of carbon fiber, Pearl River Shipping sent a working group to conduct research on a global scale. The survey results show that Norway is at the world's advanced level in composite material technology and application promotion, and Norway's BrAa shipyard is at the world's leading level in carbon fiber commercial ship manufacturing technology.

Subsequently, the company organized the Pearl River Delta shipowners to Norway for field visits and exchanges, through the field experience of the practical application of carbon fiber ships in various regional routes in Norway, and learned that carbon fiber ships have the advantages of fast speed, low fuel consumption, high production efficiency, low vibration noise, strong fatigue resistance and corrosion resistance, high manufacturing accuracy, and can shape the appearance of complex curves. "In the process of introducing and building carbon fiber ships, we got strong support from China Classification Society. They sent an expert team to work with Pearl River Shipping technical team to study the construction specifications in combination with the problems encountered in the practice process, and finally conquered the key technology of carbon fiber hull structural strength check calculation."

Chinese and foreign shipping enterprises jointly develop and build transnational marketing network

Huang Chuanfei said that after Zhujiang Shipping bought into BrAa shipyard, it promoted the transfer of excellent ship design and production process technology, and trained a group of R & D, design and production technicians. In addition, the cooperation framework and working mechanism of the two shipping companies to jointly explore the market and build a marketing network have been determined and started to implement.

Huang Chuanfei said that through practice, it is very important to go out and establish stable cooperative relations with foreign companies. "The two sides continue to explore overseas demand and innovative technology applications, and can quickly contact and respond to customer needs, laying the foundation for the establishment of a transnational marketing network."

Huang blooming told reporters that in the European port can be seen, the pier gathered restaurants, coffee shops, citizens and visitors linger among them. "It is both a public pier, a leisure pier and a place for cultural travel, bringing together many functions." He suggested that Guangzhou can also do a good job in the boat terminal public supporting facilities, combined with water sports and cultural tourism needs of the ocean culture (water culture), further boost the Marine economy.

The largest government ship construction base in China:

The development of Marine engineering has become an important direction of transformation

CSSC Huangpu Wenchong Shipping Co., LTD. Changzhou factory is located at the throat of the Pearl River Golden Waterway in Guangzhou. From the "Three major naval battles" in the early days of the founding of the People's Republic of China to the "828 Project", the Navy's first deep dive test, and then to the construction of "China's first boat", Huangpu Wenchong has grown all the way with the People's Navy, laying a solid foundation for military enterprises.

According to reports, the plant area to medium and small surface combat ships, ocean engineering auxiliary ships, large government ships as the leading products, supplemented by military auxiliary ships, military trade ships, transport ships. With the advantages of military technology, the business of public vessels in Changzhou Factory has also developed rapidly. Various types of customs anti-smuggling boats, patrol boats, coast guard vessels, fishery administration vessels, Marine surveillance vessels, rescue vessels and coast guard vessels have been built successively for the General Administration of Customs, Frontier Public Security, State Oceanic Administration, State Maritime Safety Administration, Rescue and Salvage Bureau of the Ministry of Transport, and other government departments. It has become the largest and strongest government ship construction and support base in China.

The production capacity of offshore industry has developed by leaps and bounds

It is understood that the history of Wenchong factory dates back to 1955, and the public-private joint venture Guangzhou Ship repair plant was formally established. Over the past 60 years, Wenchong Factory has experienced from public-private joint venture units to wholly-owned state-owned enterprises, from a small scale, simple facilities, backward craft ship repair factory to the construction of "China First Dock", with more than 100,000 tons of ship repair capacity of modern enterprises, has cast Wenchong ship repair brand and branch container ship, dredger two major shipbuilding brands, and actively explore the non-ship market.

Huangpu Wenchong Shipyard

The relevant person in charge of the company introduced that Huangpu Wenchong is the pioneer of domestic offshore engineering equipment manufacturing, and is one of the earliest fixed-point production plants for offshore oil extraction platforms in China. Since the beginning of the 21st century, according to the strategic layout of CSSC, Huangpu Wenchong has taken the development of Marine engineering as an important direction of transformation and upgrading, invested nearly 3 billion yuan in the construction of Longjian New factory in Nansha, Guangzhou, and achieved leapfrog development of Marine production capacity, and has undertaken and built more than 40 kinds of high-tech Marine engineering equipment. In 2012, Huangpu Wenchong, TSC Group and ZENTECH Design Company jointly launched a new generation of 400-foot jack-up drilling platform for the global offshore industry market, and successfully undertook orders for offshore industry platforms such as wind power installation platform, offshore industry residential platform, and multi-functional service platform. "Whampoa Wenchong has successfully entered the high-end field of mainstream offshore equipment manufacturing, and its products have covered the main stage of offshore oil and gas resource development, becoming one of the most important offshore engineering construction bases in China."

Regional container ships welcome new development opportunities

In the face of the depressed Marine industry market environment, Huangpu Wenchong takes the initiative to grasp the new situation and new changes in the development of the civilian goods market, and strives to find a breakthrough in the business dilemma.

On the basis of the construction of projects already undertaken, the company continuously improves the comprehensive capabilities of detailed design and production design of Marine engineering, and strives to promote the transformation and upgrading of offshore platforms, high-tech offshore vessels and offshore auxiliary vessels, and continues to build the brand of Huangpu Wenchong Offshore Industry. In addition, relying on the new special engineering ships under construction, through upgrading and optimization, innovative research and development, high-end development to drive demand, create demand, and further explore the market; For feeder container ships, dredgers and other products that have formed brand series, we will promote the upgrading of ship types and lead the market with green, environmentally friendly, efficient and intelligent ships.

According to reports, since 2016, the transaction of new regional container ships has been more active. At present, in the stage of slow rise of the whole shipping market, coupled with the strengthening of intra-regional trade and the replacement demand of the regional ship market itself, regional container ships have ushered in new development opportunities. "The new ship type must not only meet the requirements of low energy consumption, low emissions, and new shipbuilding regulations, but also ensure the loading capacity." Therefore, large-scale, intelligent, dual fuel, environmental protection and energy saving, ice area enhancement, refrigerated container ships may be hot market in the future."

To support Guangzhou in expanding and strengthening its Marine engineering and shipbuilding industries

"Promote the transformation and upgrading of the main shipbuilding industry, strive to transform into a technology-based enterprise, and support Guangzhou to grow bigger and stronger Marine engineering and shipbuilding industry." The person in charge said that with the support of CSSC and the provincial Office of Science, Technology and Industry for National Defense, Huangpu Wenchong is committed to building two domestic leaders in ship three-dimensional design and ship intelligent manufacturing, and will help Guangzhou become a domestic high-end ship offshore equipment research and development and innovation center.

The person in charge also introduced that Huangpu Wenchong took the lead in the construction of dual-fuel port tugs in China, and is building dual-fuel container ships, "in the future, more energy-saving, safe and environmentally friendly ships can be built to provide support for Guangzhou to vigorously develop low-carbon shipping."

Century-old Dock high dance industry "leader" :

Promote the localization of supporting equipment and drive the development of industrial chain

The predecessor of Guangshu International was established on August 1, 1954 by the former Ministry of Machinery Industry on the basis of the original "Guangnan Dock", and the "Guangnan Dock" can be traced back to the Republic of China period, was founded in 1914 by shipping merchants Tan Yuxiu, Tan Liting father and son on the Pearl River in Liwan District, so far has gone through a long century.

Master the core technology of high-tech and high value-added ship type manufacturing

Today, the company's main factory is located in Longxue Island, Nansha, Guangzhou, covering an area of 3.02 million square meters, with 5,200 meters of deepwater dock shoreline, annual shipbuilding capacity of 3.6 million deadweight tons, and annual repair capacity of more than 200 vessels.

According to the relevant person in charge of CSSC Guangshan International Co., LTD., Guangshan International has gradually developed into the most important auxiliary ship construction and support base in South China since its establishment. It is understood that the company has mastered the core technology in the construction of high-tech and high value-added ship types such as ships, full series of liquid cargo ships, bulk carriers, large container ships, luxury passenger rolling ships, semi-submersible ships, polar ships, research ships, official ships and special ships, and the construction of portable liquid cargo ship series products has formed the brand effect of "Guangsheng International portable liquid cargo ship". The very large oil carrier VLCC and the very large ore carrier VLOC independently developed and built by the company are more favored by domestic and overseas markets.

Orders return to rational energy saving, high-end market demand increases

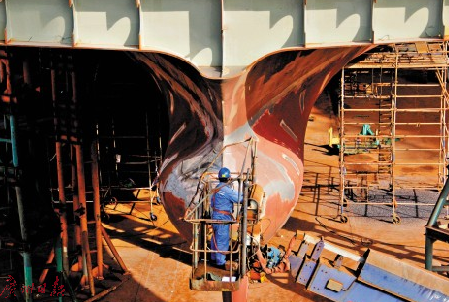

In the shipbuilding base of Longxue Island, several huge ships are emerging, and every working day, tens of thousands of technical workers are busy here, and the sound of whistle, banging on the hull, and the sound of huge gantry cranes moving along the track can be heard.

Workers are busy working in the factory of Guangship International

According to the relevant person in charge, from the perspective of orders, the shipbuilding industry has shown the following two trends: First, the volume and price of new ship orders have gradually returned to rationality. Since the financial crisis in 2008, the trading volume and transaction price of the new shipbuilding market have fallen off a cliff. Due to the global shipbuilding overcapacity, under the influence of the market, global shipbuilding enterprises have undergone two rounds of adjustment, namely bankruptcy liquidation and merger and reorganization. The number of active shipyards with orders or delivery records for ships over 10,000 tons decreased from 440 to about 180 in 2016; In 2020, affected by the epidemic and the market correction, the number of shipyards receiving orders or delivering ships fell to about 150. After the significant reduction of shipbuilding capacity, coupled with the demand for new ships has gradually returned to normal track, so the volume and transaction price of new ships have gradually returned to rationality.

Second, the market demand for new energy-saving ships and high-end ships is increasing. In recent years, with the gradual acceleration of IMO legislation on environmental protection, relevant conventions such as ballast water and sulfur discharge have come into force one after another. The introduction of these new rules and regulations has further spawned the demand for new energy-saving ships and high-end ships.

Implement the "six stability" and "six guarantees" to expand domestic advantages

In July last year, the luxury passenger rolling ship "Badji Mukhtar III" produced by Guangzhou Shipbuilding International officially set sail for the port of Algiers, the biggest feature of the ship is that the internal materials and most of the equipment to achieve domestic production.

The relevant person in charge believes that vigorously promoting the localization of ship manufacturing supporting equipment is the specific measure for the company to implement the new development pattern with the domestic cycle as the main body and the domestic and international double cycle promoting each other, and it is the specific requirement for the implementation of the "six stability" and "six guarantees" in the "stability of the industrial chain and supply chain".

In addition, promoting the localization of supporting equipment is also an inherent demand for the company's high-quality development. On the one hand, affected by the epidemic, the after-sales service of imported equipment is easy to keep up, if the use of domestic supporting, suppliers are more guaranteed; On the other hand, domestic materials and equipment still have great advantages in cost performance. "In fact, most of the domestic materials are of very good quality, such as interior decoration materials for luxury passenger rolling boats, various kinds of hardware, lighting, in these areas, China itself has a strong advantage."

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands