Fanuc A16B-3200-0110 CNC System Module

Equipment status monitoring: Collect emergency stop, travel limit, door lock and other signals through digital input interface, provide real-time feedback on equipment safety status, and cut off the power supply of the driver through digital output interface when triggering abnormalities to ensure operational safety;

Production line integration: In automated production lines, communication with PLCs (such as Fanuc PMC) through RS485 interfaces enables collaborative work between CNC equipment and other equipment on the production line (such as cutting robots).

Key points for installation and maintenance

Installation requirements:

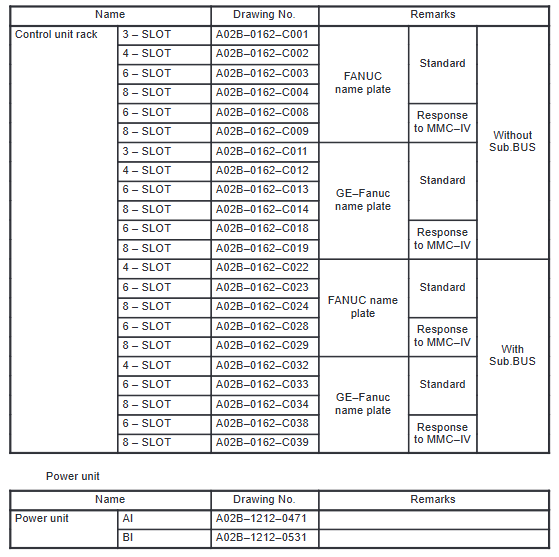

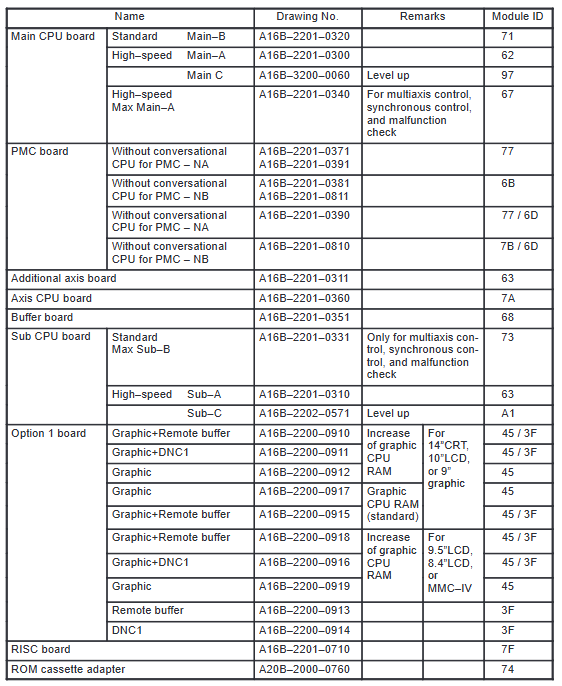

It needs to be installed in the designated slot of the Fanuc standard CNC system cabinet and fixed with screws to ensure good grounding between the module and the cabinet (grounding resistance ≤ 1 Ω);

Wiring must strictly follow the module terminal definition diagram (terminal table attached in the document), and the positive and negative poles of the power supply must not be reversed. Digital input/output signals should distinguish between dry/wet contact types to avoid module damage caused by incorrect connections;

Maintenance precautions:

Regularly check module heat dissipation (modules without fans rely on natural heat dissipation, and the ventilation inside the cabinet needs to be good to avoid temperatures exceeding 55 ℃);

If the module indicator lights (such as power lights, communication lights) are abnormal (such as power lights flashing, communication lights turning off), it is necessary to first check the power supply and cables, and then determine whether the module is faulty;

When replacing a module, it is necessary to record the parameters of the original module (such as communication baud rate and output contact configuration), and reconfigure the parameters of the new module to ensure compatibility with the system.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com