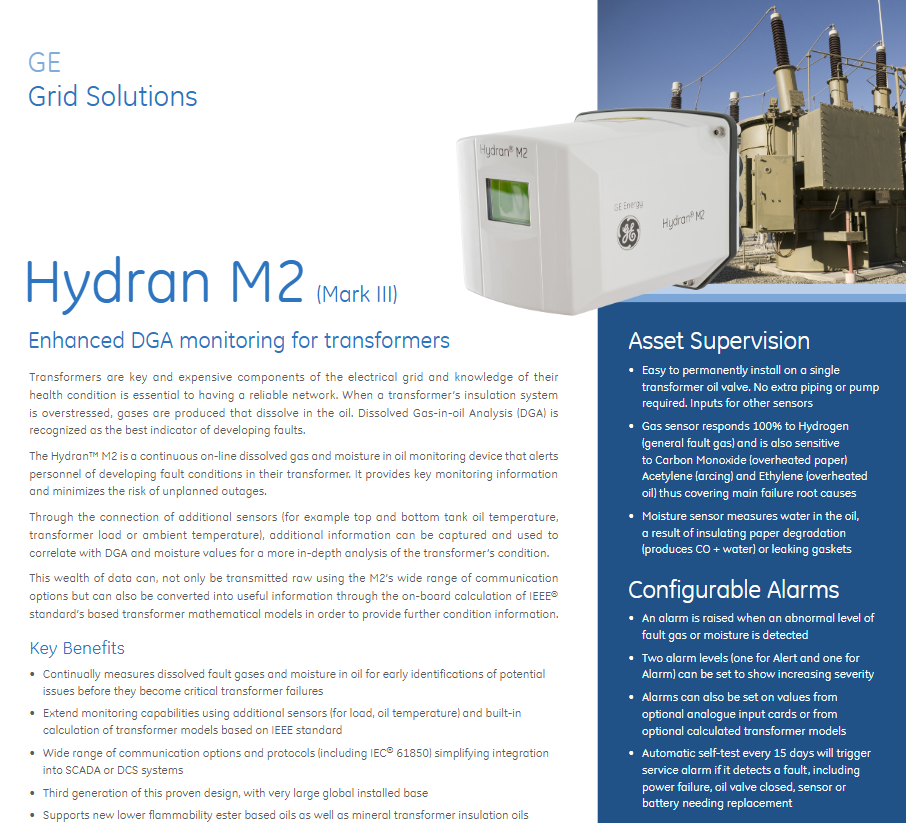

GE Grid Solutions Hydran M2 (Mark III) Enhanced DGA monitoring for transformers

GE Grid Solutions Hydran M2 (Mark III) Enhanced DGA monitoring for transformers

Core positioning and product value

Hydran M2 (Mark III) is GE's third-generation transformer condition monitoring equipment, based on Dissolved Gas Analysis (DGA) technology (an industry recognized core tool for transformer fault warning). By continuously monitoring the dissolved gas and moisture content generated by insulation system stress in the insulation oil, it achieves a full process management of "early fault identification risk assessment operation and maintenance decision support". Its core positioning is:

Guardian of key assets in the power grid: for transformers (high-value and high impact core equipment in the power system), to avoid unplanned shutdowns caused by insulation failures;

Multi dimensional state analysis platform: not only monitors the basic gas and moisture, but also can be connected to additional sensors (such as oil temperature and load current), combined with IEEE standard mathematical models, to output in-depth analysis results of transformer health status.

Core Product Value

Fault early warning: Continuously monitor the fault gases (such as hydrogen, acetylene, ethylene) and moisture, issue an alarm before the fault develops into serious damage, and avoid sudden shutdown;

Improved operation and maintenance efficiency: No need for regular manual sampling and testing, reducing on-site operation and maintenance workload, while supporting remote data transmission, achieving centralized asset management;

Wide compatibility: compatible with traditional mineral insulation oil and new low flammability ester insulation oil (natural/synthetic), covering transformers of different ages and types;

Reliability verification: The third-generation mature design has a large global installation base, has undergone long-term on-site verification, and complies with RoHS environmental standards.

Core functions and monitoring capabilities

(1) Basic monitoring function: gas and moisture monitoring

Hydran M2 achieves precise monitoring of key indicators in transformer insulation oil through dedicated sensors, covering the gas characteristics of the main types of transformer faults:

Monitoring indicators, sensor types, core monitoring targets, and fault associations

Dissolved Fault Gas Fuel Cell Type (Breathable Membrane Design) - Hydrogen (H ₂, 100% Sensitivity): A universal fault gas that can be generated by insulation oil/paper overheating and partial discharge;

-Carbon monoxide (CO, 15% sensitivity): insulation paper overheating;

-Acetylene (C ₂ H ₂, 8% sensitivity): Arc discharge (severe fault signal);

-Ethylene (C ₂ H ₄, 1.5% sensitivity): Overheating of insulation oil

Moisture in oil film capacitive type (immersion type) monitors the relative humidity (RH) in oil, reflecting the aging of insulation paper (moisture generation) or leakage of sealing gasket (external moisture intrusion). Excessive moisture will accelerate insulation degradation

Key parameters for gas monitoring

Monitoring range 0-2000 ppm (volume ratio, calculated as H ₂ equivalent value)

Measurement accuracy ± 10% reading ± 25 ppm (H ₂ equivalent value)

Repeatability ± 5% reading or ± 5 ppm (whichever is greater)

Response time of 10 minutes (reaching 90% of the step change)

Key parameters for moisture monitoring

Measurement range 0-100% RH (relative humidity)

Measurement accuracy ± 2% RH

Repeatability ± 2% RH

(2) Expand monitoring and analysis capabilities

Multi sensor access: Supports external 4-channel analog input modules and can be connected to the following key parameter sensors to achieve linkage analysis of "gas moisture operating conditions":

Environmental temperature sensor;

Transformer top/bottom oil temperature sensor;

Load current sensor (split core CT, 4-20mA output).

IEEE standard mathematical model calculation: based on multi-dimensional data access, built-in transformer health status model that complies with IEEE standards, outputting intuitive operation and maintenance decision basis. The core model output includes:

Estimation of winding hotspot temperature (assessment of insulation thermal aging risk);

Moisture content in insulation paper (which better reflects the true aging state of insulation paper than moisture in oil);

Moisture bubbling temperature (warning of insulation breakdown risk caused by water analysis in low-temperature environments);

Insulation aging degree, overload capacity, cooling efficiency, temperature difference of on load tap changer (OLTC), etc.

(3) Alarm and self diagnostic functions

Multi level alarm configuration: supports flexible setting of alarm thresholds, covers different levels of fault severity, and avoids false alarms or missed alarms:

Gas alarm: can be triggered based on "absolute value of gas concentration" and "hourly/daily trend" (gas growth rate);

Moisture alarm: can be triggered based on "absolute value of moisture concentration" and "average moisture level";

Extended alarm: supports triggering alarms based on external sensor data (such as high oil temperature) and model calculation results (such as winding overheating);

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA