EMERSON A6110 axis relative vibration monitor

EMERSON A6110 axis relative vibration monitor

Product Overview

The A6110 axis relative vibration monitor is designed specifically for the most critical rotating machinery in factories and has extremely high reliability. As a 1-slot monitor, it can be used in conjunction with other AMS 6500 monitors to build a complete API 670 mechanical protection monitoring system, suitable for applications such as steam, gas, compressor, and hydro turbine machinery. Its main function is to accurately monitor the relative vibration of the shaft, and drive the alarm and relay by comparing the vibration parameters with the alarm settings, thereby reliably protecting the machinery.

The relative vibration monitoring of the shaft is achieved through displacement sensors, which can be installed inside the bearing box or bearing seat, targeting the rotating shaft. Due to the installation of displacement sensors on bearings, the monitored parameter is the relative vibration of the shaft, that is, the vibration of the shaft relative to the bearing housing. On all sliding bearing machines, shaft relative vibration is an important measurement parameter for prediction and protection monitoring, suitable for situations where the machine housing has a relatively large mass relative to the rotor, and the bearing housing is expected to not vibrate within the machine speed range from zero speed to production state.

AMS 6500 is PlantWeb ® Components of AMS software. PlantWeb will collaborate with Ovation ® And DeltaV ™ The operation integration of process control system and mechanical health status is provided to users; AMS software provides maintenance personnel with advanced predictive and performance diagnostic tools, helping to accurately diagnose machine failures as early as possible.

Main parameters

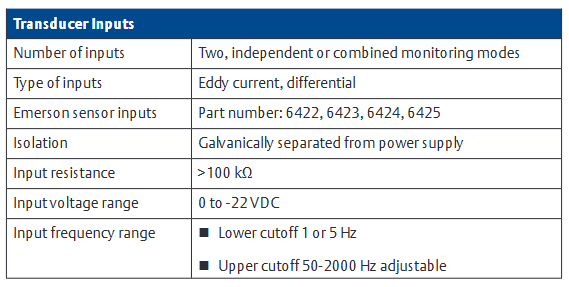

Sensor Input

Input quantity: 2, supporting independent or combined monitoring modes.

Input type: eddy current, differential.

Emerson sensor inputs: models 6422, 6423, 6424, 6425.

Isolation: Galvanically separate from the power supply.

Input resistance:>100 k Ω.

Input voltage range: 0 to -22 VDC.

Input frequency range: lower limit cutoff 1 or 5 Hz, upper limit cutoff 50-2000 Hz (adjustable).

Measurement range

Scope: It can be continuously adjusted through configuration software.

Minimum range: 0-400 mV.

Maximum range: 0-8000 mV.

Sensor power supply: An independent buffer sensor power supply that is diagonally separated from all system voltages and system supply voltages, with open and short circuit protection.

Nominal voltage: -26.7V.

Available current: nominal 20 mA, maximum 35 mA.

Front panel output

Two green LEDs indicate that each channel is functioning properly.

Two red LEDs indicate the alarm and danger status of each channel.

Front panel buffer output: 2, same as sensor input, ± 10 V, load>100 k Ω, frequency range 0.1-5 kHz (-3 dB), 0-16 kHz -3 dB ± 20%.

Mini DIN configuration socket: used for module interface connection for configuration, parameter and status monitoring, RS - 232。

Handle: A panel that facilitates card removal and provides module and sensor recognition.

analysis function

Measurement mode: Hot configurable, including multiple modes such as zero to peak, peak to peak, independent dual channel, or combined dual channel modes.

Analysis parameters: 1/2x, 1 to 10x, and the same phase angle, which can be obtained through ModBus TCP/IP output.

Rear output

Current mode output: Each channel outputs 0/4-20 mA, proportional to the main value, allowing a load of<500 Ω, with an accuracy of ± 1% of full scale, and a stabilization time of 0 to 10 seconds (configurable).

Voltage mode output: Each channel outputs 0-10 VDC, proportional to the main value, with open/short circuit protection, allowing loads greater than 10 k Ω.

Rear buffer output: The original buffer output signal (AC and DC) has open/short circuit protection, with a frequency range of 0.1-16 kHz (-3 dB), 0-16 kHz -3 dB ± 20%, and allows for a load greater than 10 k Ω.

DC voltage output: 0-10 VDC output, proportional to the shaft position (gap), with open/short circuit protection, accuracy of ± 1% of the range, allowing load>10 k Ω.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands