ABB AC500 V3 PLC Enhanced connectivity and performance

(PM5630/5650/5670/5675), achieving comprehensive upgrades in performance, connectivity, and network security while maintaining hardware compatibility.

ABB AC500 V3 PLC Enhanced connectivity and performance

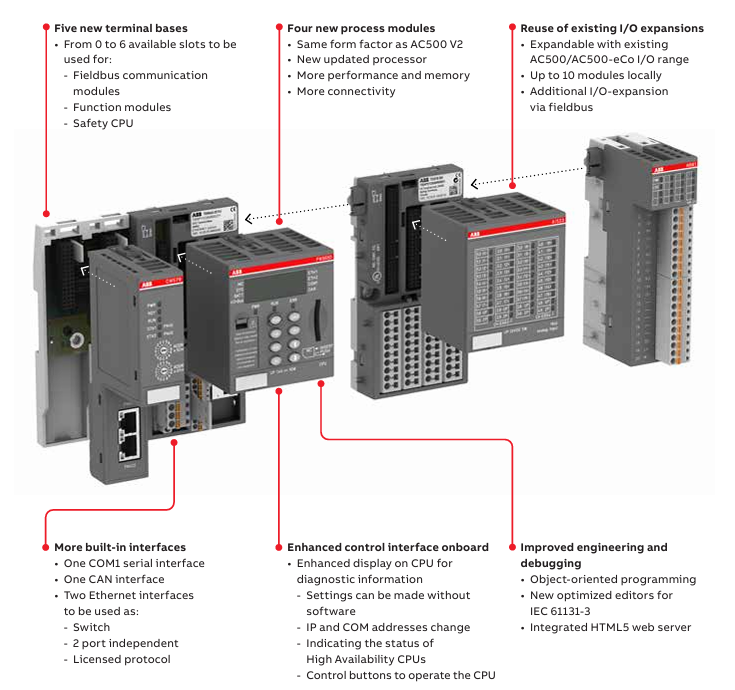

Product positioning and core architecture

AC500 V3 is the third-generation programmable logic controller launched by ABB. As a technological iteration product of the AC500 series, its core positioning is to bridge industrial automation and the Internet of Things (IoT). This series extends the original AC500 V2 platform with four new CPUs

(PM5630/5650/5670/5675), achieving comprehensive upgrades in performance, connectivity, and network security while maintaining hardware compatibility.

Architectural features are as follows

Processor and Memory: Adopting a new generation processor, the computing speed has been significantly improved. Taking PM5670-2ETH as an example, the bit operation cycle is only 0.002 μ s, which is 10 times higher than the V2 platform. It is equipped with 160MB program memory and 8GB flash drive (PM5675), supporting complex algorithms and data storage.

Dual Ethernet architecture: Two independent Ethernet interfaces onboard, configurable as switches or independent ports, supporting IEEE 802.3 standard, integrated with web servers and multiple industrial protocol stacks, without the need for additional communication modules.

Core technical characteristics

1. Performance and computational capability

Instruction efficiency: Supports bit/word/floating-point operations, with the floating-point operation cycle shortened from 0.120 μ s in V2 to 0.002 μ s (PM5670), meeting the requirements of high-speed closed-loop control.

Memory allocation: Programs, data, and web memory are independently partitioned, supporting dynamic allocation. It can run up to 200+task instances simultaneously and is suitable for multi axis motion control and complex logical operation scenarios.

2. Industrial communication and protocol support

Fieldbus integration:

Control layer: Built in CANopen master station, Ethernet IP (under development) Modbus TCP/RTU, Supports PROFINET and EtherCAT (requires module expansion).

Management: OPC UA Server supports data access and alarm services, MQTT client connects to cloud platform through TLS encryption to achieve device data cloud (such as ABB Ability) ™ Platform).

Special fields: KNX (Building Automation), BACnet (Intelligent Buildings), IEC 61850 (Substation Communication) and other protocols are activated through license to adapt to cross industry requirements.

Network topology flexibility:

Dual ports can be configured as "redundant ring network" or "three-layer routing", for example, port 1 connects to the factory intranet (OPC UA), and port 2 connects to the Internet (MQTT), supporting port mirroring and traffic monitoring.

3. Network security design

Firmware protection: Hardware security chips implement firmware digital signatures to prevent malicious tampering; The transmission of engineering files adopts AES encryption and is integrated with ABB Ability ™ Two way certificate authentication is required for Automation Builder.

Communication encryption: HTTPS/FTPS is used for file transfer, OPC UA supports role-based access control (RBAC), MQTT messages are encrypted through TLS 1.2 to block man in the middle attacks.

Special Version: AC500-XC V3 (Extreme Environment Type)

Designed for harsh industrial scenarios, with multiple environmental adaptability certifications:

Climate adaptability:

Temperature: -40 ° C to+70 ° C for continuous operation, meeting the needs of cold storage and metallurgical high-temperature areas.

Humidity: 100% humidity+condensation protection, meets G3 level corrosion standards, suitable for offshore platforms and chemical workshops.

Mechanical reliability:

Vibration: 4g root mean square random vibration (500Hz), 2g sine vibration, tested according to IEC 60068-2-6, suitable for construction machinery.

Altitude: 4000 meters (620hPa pressure), supporting the application of power stations in high-altitude areas.

Engineering Tools and Development Process

ABB Ability ™ Automation Builder

Integrated development: integrating PLC programming (IEC 61131-3), safety logic (Safety PLC), HMI configuration, driver debugging, supporting cross device collaborative development.

Simulation and testing: Offline simulation function (under development) can simulate CPU operation, verify program logic without hardware, and shorten debugging cycle.

Version control: Built in Subversion client, supports collaborative development among multiple people, automatically records code change history, and reduces project risks.

Model Supplement

ABB PPD113 B01-25-111000 3BHE023784R2530

ABB SC560

ABB SPASI23

ABB SPBRC400

ABB CI546 3BSE012545R1

ABB 3HAB8101-18/09A

ABB 3BHL000986P7001

ABB HBFFAEAGNBA1BAA11G

ABB 5SHX1960L0006 3BHB016120R0002 3BHE019719R0101 GVC736BE101

ABB NBIO-31 3BSE011337R1

ABB A30-30-10RT

ABB T3N225

ABB 7625013-S

ABB 129740-002 134177-001

ABB GFD233A103 3BH022294R0103

ABB AO810

ABB MVR 0.44-10KA

ABB PCD235A101 3BHE032025R0101

ABB PM865 3BSE030193R1

ABB RXIDK 2H 1MRK000838-HA

ABB SAFT183VMC

ABB 3BHB004661R0001 KUC711AE

ABB PM856AK01 3BSE066490R1

ABB 206-00212

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands