ABB AO2000-LS25 Laser analyzer

ABB AO2000-LS25 Laser analyzer

Product overview

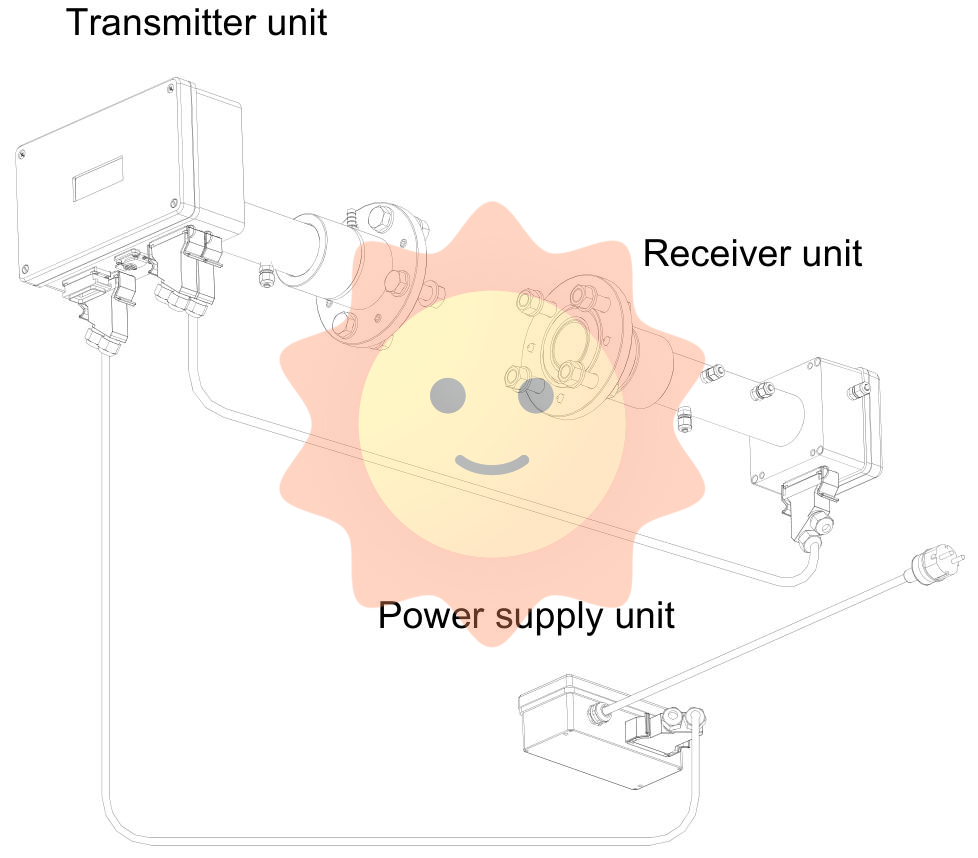

AO2000-LS25 is a laser analyzer launched by ABB, available in both universal and explosion-proof versions, designed to make measurement simple. It is based on the principle of Tunable Diode Laser Absorption Spectroscopy (TDLAS) and consists of three independent units: transmitter unit, receiver unit, and power supply unit. It can be used for continuous in-situ gas monitoring in chimneys, pipelines, process rooms, and other places.

Measurement principle

Using infrared single line absorption spectroscopy, each gas has a unique absorption line at a specific wavelength. By scanning the absorption line of the target gas and using wavelength modulation technology, the gas concentration is measured using second harmonic signals, and the measurement is only for free molecules of specific gases, without being affected by molecules that bind to other molecules or adhere to particles.

Instrument Description

Transmitter unit: including laser module, collimating optical components, and main electronic equipment, placed in a coated aluminum box.

Receiver unit: equipped with a focusing lens, photodetector, and receiving electronic device, also inside a coated aluminum box.

Power supply unit: converts 100-240V AC to 24V DC, which can directly supply power to the transmitter unit and connect 4-20mA input signals from external temperature/pressure sensors.

Protection and Performance: The protection level of the transmitter and receiver units is IP66, and the standard optical window can withstand an absolute pressure of up to 5 bar. The optical alignment is simple and reliable, and the blowing function can prevent dust and other pollutants from contaminating the optical window.

Software

User invisible programs integrated into CPU electronic devices, used to perform all necessary calculations and self-monitoring tasks.

A Windows based program that communicates with the instrument through an RS-232 connection for installation, service, and calibration, and does not require use during normal operation.

Laser classification and warning

When measuring oxygen, the laser is classified as Class 1M, and other sample components are classified as Class 1, in accordance with IEC 60825-1 standard. The laser emits invisible light.

Warning: 1M class laser products cannot be opened when powered on and cannot be viewed directly with optical instruments; Class 1 laser products cannot be opened when powered on.

Installation preparation

(1) Tools and other equipment

Two M16 bolt open-end wrenches, one 5mm hex wrench, one 2.5mm flathead screwdriver, and one 386 or higher configuration PC are required.

(2) Measurement point flow conditions

It is recommended to have at least 5 straight pipe sections with chimney diameters before the measurement point, and 2 straight pipe sections with chimney diameters after it.

(3) Monitor placement

The transmitter and receiver units should be easily accessible, and the receiver unit should have at least 1 meter of free space outward from the flange fixed on the chimney.

(4) Requirements for flanges and chimney holes

Two holes with a diameter of at least 50mm and diametrically opposite are required. The standard flange is DN50/PN10. The initial angle and alignment of the flange after welding must meet certain tolerance requirements. After adjustment, the maximum allowable angle drift between the laser beam and the central axis of the receiver unit caused by temperature or vibration is ± 0.3 °.

(5) Cable and electrical connections

The transmitter and receiver units are connected using the accompanying receiver cable, with a modified cable length not exceeding 20 meters.

The service PC cable is 3 meters long and can be extended to about 10 meters.

The maximum length of the power cable is 100 meters, the maximum length of the receiver cable is 150 meters, and the maximum length of the Ethernet cable is 100 meters or longer (depending on the local network configuration).

Installation

(1) Installation and adjustment

Install the alignment and blowing unit of the transmitter and receiver onto the flange according to the steps, perform blowing gas installation, window adapter ring installation, equipment body installation, cable connection and other operations.

Air blowing is used to keep the instrument window clean. The blowing gas should be dry and clean. It is recommended to use instrument air with a flow rate of about 20-50 liters/minute. Some applications require nitrogen blowing. The blowing flow rate of the transmitter and receiver units should be less than 0.5 liters/minute.

For applications involving toxic and highly corrosive gases, isolation flanges should be used, and process safety or thorough purging should be ensured before installation.

(2) Start up

When the electronic device is started, the LCD will display the startup mode information. The laser will only be turned on after the laser temperature stabilizes during the startup process, and the startup usually lasts less than 3 minutes.

After startup, it may display "laser alignment error" and "low transmission", which are normal phenomena indicating that the transmitter and receiver units are not aligned.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands