Baldor BSM Series AC Servo Motor Analysis

Baldor BSM Series AC Servo Motor Analysis

ABB Baldor-Reliance® BSM series AC servo motors represent the high-performance standard in industrial automation. This comprehensive product line covers everything from the low-inertia, high-dynamic-response N series to the high-inertia, universally matched C series, and the stainless steel SSBSM series designed for harsh environments. This article provides an in-depth analysis of the core technical features, performance advantages, and selection guidelines of the BSM series, helping engineers optimize motion control solutions.

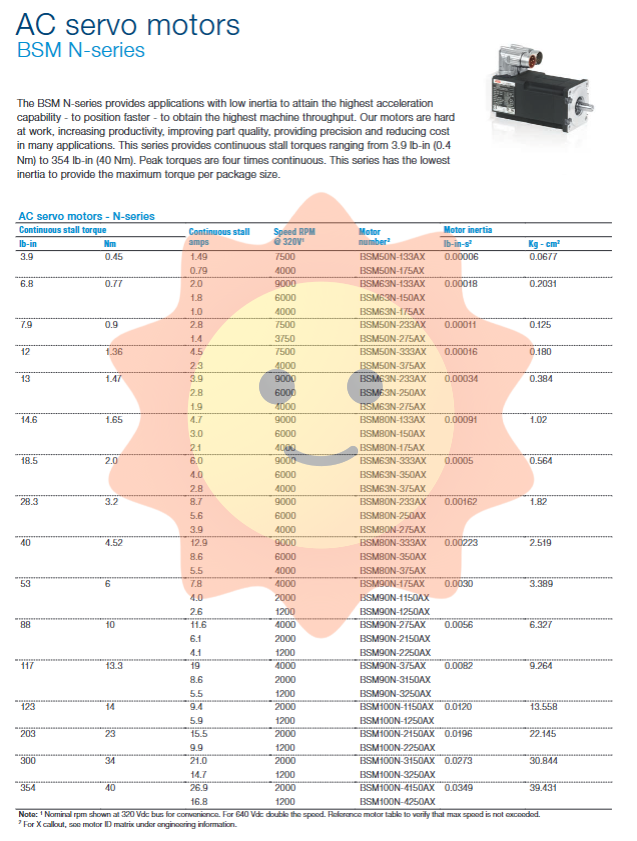

1. BSM N Series: Low Inertia, High Dynamic Response

The BSM N series is designed for precision equipment requiring extremely fast positioning and high productivity. Its core advantage lies in its superior torque-to-inertia ratio.

Extreme Acceleration Performance: This series offers the industry's lowest rotor inertia, enabling acceleration from 0 to top speed in an extremely short time.

Overload Capacity: The N series motors deliver peak torque up to 4 times the continuous torque, providing tremendous acceleration torque and significantly shortening machine cycle times.

Magnetic Materials: Utilizes neodymium iron boron (NdFeB) magnets, ensuring strong magnetic field strength within a compact size.

Typical Applications: Electronic semiconductor pick-and-place machines, high-speed packaging machinery, feed axes of CNC machine tools, printing equipment.

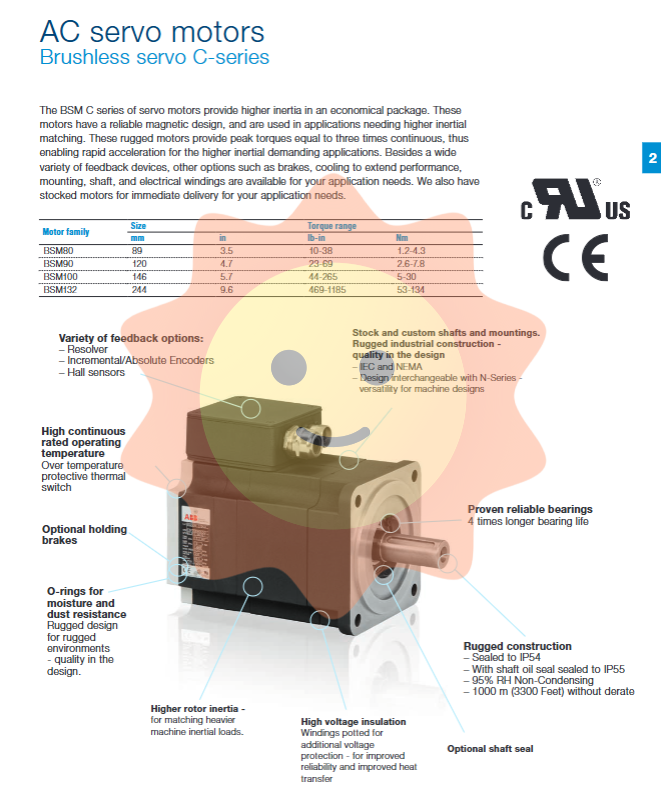

2. BSM C Series: High Inertia, Versatility, and Economy

The BSM C Series is ideal when load inertia is high or smoother operating characteristics are required. It offers an affordable solution while maintaining high performance.

Inertia Matching: With a higher rotor inertia than the N Series, it better matches heavy loads driven directly or geared loads, reducing current surges to the drive.

Compact Design: C Series motors are approximately 2 inches (50 mm) smaller than older models while providing the same or even higher torque density, saving valuable mechanical installation space.

Overload Capacity: Peak torque is typically three times that of continuous torque, enabling it to handle intermittent high load demands.

Typical Applications: Material handling systems (conveyors), winding machines, general industrial automation, machine tool spindles.

3. SSBSM Series: All Stainless Steel, Resistant to Harsh Cleaning Environments

For food and beverage, liquid handling, pharmaceutical, and environments where corrosive substances are present due to rinsing, the SSBSM series offers unparalleled durability and compliance.

Protection Rating: Standard design meets IP67 protection rating and can operate safely under high-pressure water rinsing conditions up to 1500 psi (103 bar).

Hygienic Design: All electrical connectors are made of stainless steel with laser-etched nameplates for easy cleaning and no unsanitary areas.

Corrosion-Resistant Materials: 304 stainless steel housing and 416 stainless steel shafts, combined with Viton O-rings, ensure long service life in high humidity or corrosive environments.

Bearing Protection: Uses double-sealed bearings with Viton seals and H1-grade grease (FDA-compliant food contact grease) for added safety.

4. Core Technological Advantages and Universal Features

Regardless of the series chosen, BSM motors share a range of core technological features designed to enhance reliability and adaptability:

Wide Voltage Range and Feedback Compatibility: Supports 160V, 320V, and 650V DC bus voltages, and can be equipped with various feedback devices such as resolvers, incremental encoders, absolute encoders, or Hall sensors to meet diverse application needs, from basic speed regulation to high-precision positioning.

High-Performance Insulation and Encapsulation:

Potted Stator: The windings are potted with epoxy resin, providing additional voltage protection against surges and significantly improving heat dissipation.

Protection Rating: Standard motors offer IP54 protection (up to IP55 with oil seals), providing dust and splash protection; stainless steel models reach IP67.

Forced Cooling Option: For applications requiring continuous high torque output, some models offer a rear-mounted cooling fan. This option can increase the motor's continuous stall torque by 60% (some high-power models), effectively extending the motor's operating range.

Brake Optional: All series are available with a holding brake (24VDC) suitable for vertical axis applications or emergency stop requirements.

Bearing Technology: High-quality ball bearings with an anti-rotation front bearing structure (preventing axial movement) provide a design life of tens of thousands of hours.

5. Performance Curve Interpretation and Selection Strategy

Correctly interpreting the speed-torque curve is crucial during the selection process. ABB's curves clearly show the continuous and peak torque ranges at different bus voltages.

S1 Zone (Continuous Operation Zone): The shaded area below the curve. Within this zone, the motor can operate for extended periods without exceeding the rated winding temperature limit of 155°C. The design should ensure that the torque required by the load falls within this zone.

S2 Zone (Intermittent/Acceleration Zone): The blank area above the curve. This zone is only permitted for brief periods during acceleration or deceleration. The motor can only operate in this zone for short periods; otherwise, the overheat protection switch will activate.

Voltage vs. Speed Relationship: Rated speed is typically based on a 320V DC bus voltage; if using 640V, the speed will double. When selecting a model, it is necessary to confirm the relationship between the actual bus voltage and the maximum speed.

6. Application Areas and System Integration

The BSM series AC servo motors are designed for harsh industrial environments and are widely used in the following fields:

Packaging and Logistics: High-speed sorting machines, conveyor belts, carton sealing machines.

Machine Tools: Feed axes of milling machines, lathes, and grinding machines.

Robotics: Joint drives, pick-and-place mechanisms.

Food Processing: Slicers, mixers, filling machines.

Seamless Integration: ABB BSM series motors do not exist independently; they form a perfect motion control system with ABB's MicroFlex e150, MicroFlex e180, and MotiFlex series servo drives. This seamless matching between motors and drives optimizes the system's dynamic response, shortens development time, and maximizes energy efficiency.

Conclusion

The Baldor BSM series AC servo motors, through their diverse product portfolio (N/C series and stainless steel series), provide comprehensive solutions for industrial automation, from high-precision positioning to heavy-duty drives. Its robust industrial design, extensive optional features (cooling, braking, feedback), and superior heat dissipation ensure reliable operation under various extreme conditions. By selecting the right BSM motor, businesses can not only significantly improve production efficiency and product quality, but also achieve a long-term return on investment by reducing energy consumption and maintenance costs.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands