Rockwell Automation ControlLogix 5570 and 5560 controllers

Features ControlLogix 5570 ControlLogix 5560

Power Supply and Memory Backup Energy Storage Module (ESM) Lithium Battery (1756-BA1/BA2/BATM)

Built in communication port USB 2.0 (temporary programming only, cable length ≤ 3m, no hub) RS-232 serial port

The maximum number of connections is 500 and 250

Non volatile storage SD card (standard 1784-SD1 1GB) CompactFlash card (available separately)

Status display: 4-line scrolling text screen+4 indicator lights, 6 indicator lights (no text screen)

Representative models 1756-L71/L72/L73/L74/L75 1756-L61/L62/L63/L64/L65

Rockwell Automation ControlLogix 5570 and 5560 controllers

Product Overview and Classification

1. Controller types and core differences

The ControlLogix series controllers are divided into two major series, 5570 and 5560, as well as extreme environment type (- XT suffix) and Armor protection type (- EROM suffix). The core differences are as follows:

Features ControlLogix 5570 ControlLogix 5560

Power Supply and Memory Backup Energy Storage Module (ESM) Lithium Battery (1756-BA1/BA2/BATM)

Built in communication port USB 2.0 (temporary programming only, cable length ≤ 3m, no hub) RS-232 serial port

The maximum number of connections is 500 and 250

Non volatile storage SD card (standard 1784-SD1 1GB) CompactFlash card (available separately)

Status display: 4-line scrolling text screen+4 indicator lights, 6 indicator lights (no text screen)

Representative models 1756-L71/L72/L73/L74/L75 1756-L61/L62/L63/L64/L65

2. Special Model Description

Extreme environment type (- XT): such as 1756-L73XT/L63XT, supports working temperatures of -25~+70 ° C, and other functions are consistent with the corresponding basic model.

Armor protective type (- ROM): such as 1756-L72EROM/L73EROM, integrated with 1756-L7x controller and 2 EtherNet/IP DLR communication modules, IP67 protection level, suitable for machine installation, ESM non removable.

Installation and hardware configuration

1. Installation environment requirements

Environmental conditions: Pollution level 2 industrial environment, overvoltage category II, altitude ≤ 2000m, no derating requirements; Storage temperature -40~+80 ° C, working temperature for conventional type 0~+60 ° C, extreme type -25~+70 ° C.

Shell requirements: It needs to be installed in a shell that complies with NEMA 250 or IEC 60529 standards, with a flame retardant rating of 5VA (non-metallic shells need to be certified), and can only be opened with tools inside. The explosion-proof environment needs to additionally comply with ATEX/IECEx requirements (such as Zone 2 environment requiring an IP54 or above shell).

2. Core hardware installation steps

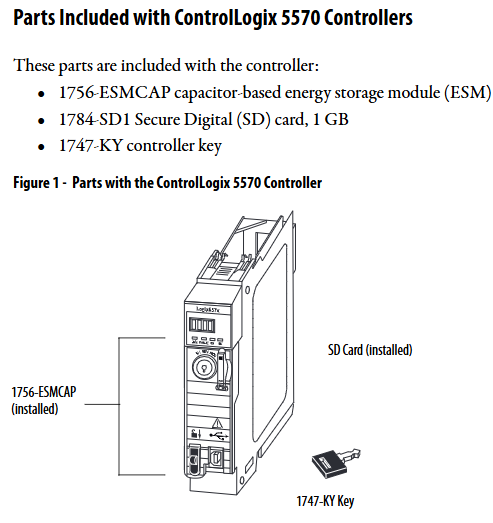

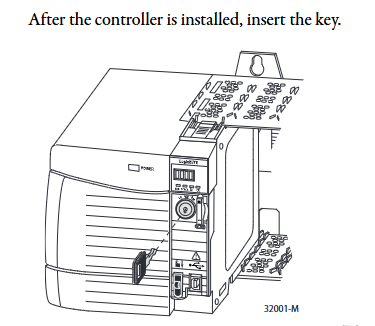

(1) Key installation of ControlLogix 5570

**Chassis and power supply pre installation * *: Chassis and power supply need to be installed according to the manuals "1756-IN621 (Chassis)" and "1756-IN619 (Power Supply)" first.

Controller insertion: Align the upper and lower rails of the chassis, slide in to the buckle lock, and ensure that it is flush with adjacent modules; Attention should be paid to the risk of electric arc in explosion-proof environment during live plugging and unplugging. It is recommended to perform power-off operation.

ESM installation: Align with the tongue and grain slot and push it into the buckle for fixation. After installation, start charging (up to 2 minutes, the status screen displays "CHRG"). Do not turn off the power before charging is complete, otherwise the program may be lost.

SD card operation: Open the SD card card, insert the 1784-SD1/SD2 card (recommended original card to avoid data damage), and press it until the card buckle locks; Before removal, it is necessary to confirm that the SD indicator light is off and that the explosion-proof environment requires power-off operation.

(2) Key installation of ControlLogix 5560

Battery installation: Series A uses 1756-BA1/BATM, Series B uses 1756-BA2, connect the positive and negative poles (red+black -), write the replacement date and paste it on the inside of the cabinet door.

CompactFlash card operation: Series A needs to lift the locking clip to insert, Series B needs to push open the buckle and insert, and before removing, confirm that the OK indicator light is green.

3. Hardware security specifications

Static protection: Before operation, touch grounded objects to discharge electricity, wear a grounding wristband, avoid touching connector pins and internal circuits, and use anti-static workstation storage devices.

Explosion proof requirements: In Class I Zone 2 (Groups A-D) environments, equipment/components can only be plugged in and out after power failure or confirmation of non hazardous areas; It is prohibited to replace non certified components, and batteries must be replaced in non hazardous areas.

Software configuration and firmware upgrade

1. Essential software and version requirements

Different controller models need to be matched with specific software versions, and the core requirements are as follows:

Controller model Studio 5000 environment minimum version RSLogix 5000 minimum version RSLinx Classic minimum version

1756-L71/L72/L73 and other V21.00.00 V20.01.02 V2.59.00

1756-L61/A - V12.06.00 any version

1756-L63XT/B - V13.04.00 V2.55.00

2. Firmware upgrade method

Supports two methods: ControlFLASH software and AutoFlash (built-in in Logix Designer). The steps are as follows:

(1) ControlFLASH upgrade

Connect the controller (USB/Ethernet), start ControlFLASH, select the controller model and network driver.

Select the target firmware version (download the matching version from the official website to avoid file corruption), click "Finish" to start the upgrade, and do not turn off the power during the process.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands