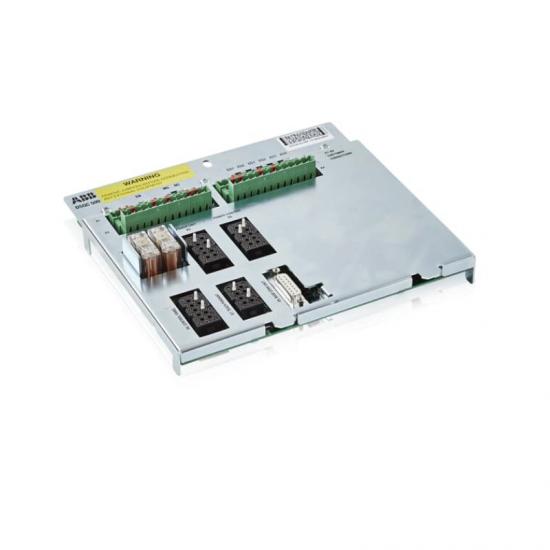

ABB DSQC509 Industrial Automation Module

ABB DSQC509 Industrial Automation Module

Product positioning and overview

DSQC509 is a modular I/O module under ABB, suitable for the industrial automation field, and is a key component of robot controllers or industrial control systems. Its design focuses on high-precision signal processing and system integration flexibility, commonly used in scenarios such as robot arms, automated production lines, and process control equipment. It can achieve the acquisition, processing, and control output of digital/analog signals, supporting efficient collaboration with upper computers, sensors, and actuators.

Core functional characteristics

Multi type signal processing

Supports digital input/output (DI/DO): adapts to switch signals (such as button and relay status), with a response speed of milliseconds, used for logical control of equipment start stop, safety interlock, etc.

Supports analog input/output (AI/AO): can connect continuous signals such as temperature, pressure, current, etc. (such as 4-20mA, 0-10V), built-in high-precision ADC/DAC conversion module, with an accuracy of ± 0.1% FS.

Pulse signal processing: Supports encoder pulse counting, suitable for motor speed monitoring or position feedback.

Modularity and Scalability

Adopting standardized guide rail installation, supporting parallel combination of multiple modules, and expanding the number of I/O points (such as 16 point DI/16 point DO or 8-point AI/8-point AO configurations).

Compatible with mainstream ABB controllers such as IRC5 and AC800M, and enables fast data exchange through bus interfaces such as PROFIBUS DP and EtherCAT.

High reliability design

Electrical isolation: Optoelectronic isolation technology is used between channels, which has strong anti-interference ability and is suitable for strong electromagnetic environments (such as steel and chemical industries).

Fault diagnosis: Built in self diagnostic function, supports channel level fault detection (such as disconnection, short circuit), and provides real-time feedback on status (power supply, communication, fault) through LED indicator lights.

Wide temperature operation: The working temperature range is -20 ° C to+60 ° C, suitable for harsh industrial environments.

Communication and integration capabilities

Supports PROFIBUS DP V1 (maximum transmission rate of 12 Mbit/s), Ethernet/IP or Modbus TCP, seamlessly integrated into industrial Ethernet or fieldbus networks.

Support seamless integration with ABB robot systems (such as RobotStudio) to achieve collaborative control between robots and peripheral devices (such as fixture opening and closing, sensor triggering).

Typical technical parameters

Structural form: Modular (rail mounted)

I/O points: 16 digital quantities+8 analog quantities (expandable)

Working voltage: 24V DC (± 10%)

Communication interface: PROFIBUS DP, EtherCAT

Processing speed: Response time per channel<1ms

Protection level: IP20 (indoor industrial environment)

Certification: CE, UL, ISO 13849 (safety related)

Application scenarios

Robot automation

Used for signal control of end tools of industrial robots, such as welding guns and grippers, to achieve tool status feedback and action triggering.

Typical case: In the automotive welding production line, DSQC509 collects sensor signals to control the lifting of the welding gun and adjust the welding parameters.

Automatic production line

Connect conveyor belts, detection equipment, and actuators to achieve logical control of material sorting and assembly processes.

For example, in an electronic assembly line, the material arrival signal is monitored through digital input to drive the robotic arm to complete component picking and placement.

Process Control and Monitoring

In the chemical, food and beverage industries, it is used to monitor analog signals such as temperature and pressure, and output control instructions to regulate equipment such as valves and pumps.

Support integration with DCS (Distributed Control System) to achieve real-time closed-loop control of process parameters.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands