Emerson DeltaV S Series Traditional I/O Modules

Emerson DeltaV S Series Traditional I/O Modules

The core I/O subsystem of the Distributed Control System (DCS) is designed specifically for industrial process control scenarios, featuring modularity, high flexibility, easy installation and expansion, and strong environmental adaptability. It can meet the needs of reliable data acquisition and control in fields such as national defense, industrial automation, and healthcare. At the same time, by being compatible with existing systems and simplifying operations and maintenance, it helps users reduce total costs.

Core advantages and values

1. Modularization and flexible construction

Hierarchical architecture: A single controller can support up to 8 I/O carriers, forming a passive bus that can connect to 64 I/O interfaces. Each interface is equipped with a dedicated terminal block, which can be flexibly installed in any I/O slot. It supports on-demand procurement of hardware (I/O cards, carriers, power supplies, etc.), which can be added step by step with system expansion.

Tool free installation: The carrier is fixed to the T-DIN rail through a buckle, and the I/O module is directly inserted into the slot, which can be assembled without tools; The terminal block corresponds one-to-one with the I/O card, and module disassembly does not require disconnecting the on-site wiring, simplifying the maintenance process.

2. Reduce installation costs and time

Integrated power supply and protection: The I/O carrier is equipped with a bus based on-site power distribution (divided into primary/secondary power supply for odd and even slots), with independent fuse protection for each slot to reduce external power distribution circuits. At the same time, it provides a 24V DC fused bus power supply to reduce wiring complexity.

Error proof design: The I/O interface is equipped with Keying Posts, which only allow matching types of I/O cards to be inserted into the corresponding terminal block to avoid accidental installation; Some terminal blocks are integrated with series fuses, which can be quickly disconnected to isolate on-site circuit faults.

3. Online expansion and high availability

Uninterrupted expansion: Supports online addition of I/O carriers (directly connected to the right side of existing carriers or installed on other rails through extension cables), and the controller automatically detects new modules and synchronizes them to the configuration database without interrupting existing I/O communication.

1: 1. Redundancy support: Four types of critical I/O cards (such as AI 4-20mA HART, DI 24V DC, etc.) are provided with redundant terminal blocks. After paired installation, the system automatically recognizes them as redundant groups. In the event of a fault, the switching is completed within two I/O bus scanning cycles. When switching analog outputs, the signal overlap is less than 5ms to ensure that the process is undisturbed.

4. On site installation adaptation and environmental tolerance

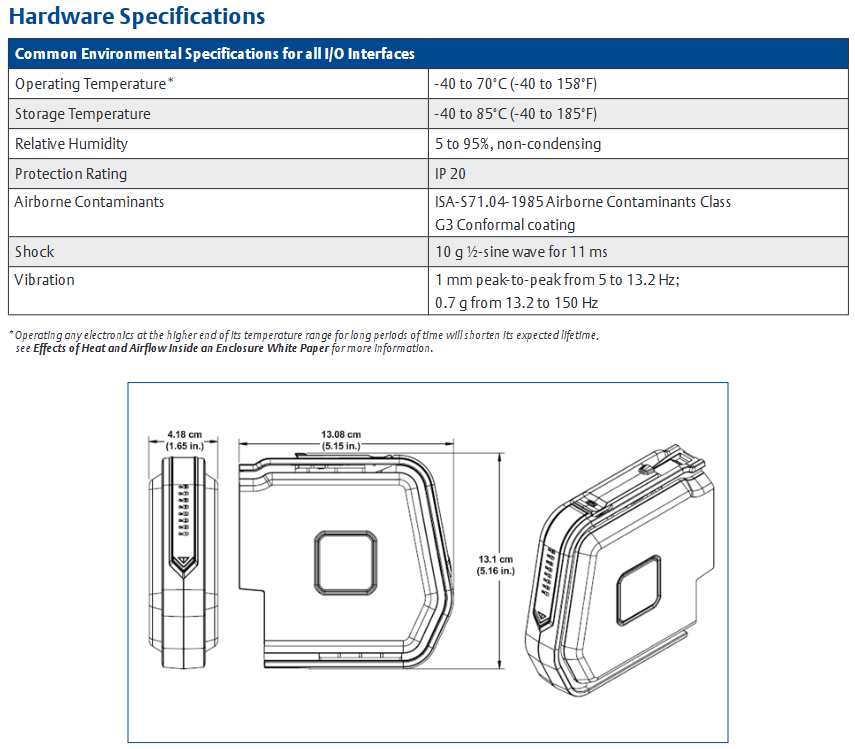

Wide temperature range and protection: All I/O interfaces operate within a temperature range of -40~70 ° C (storage -40~85 ° C), with a protection level of IP20. They can be installed in on-site cabinets to reduce control room space occupation and long-distance multi-core cable costs, without the need for intermediate wiring cabinets.

Resistant to harsh environments: Complies with ISA-S71.04-1985 G3 level anti-corrosion standards (using a conformal coating), withstands 10G half sine wave impact (11ms) and 5-150Hz vibration (1mm peak to peak/0.7G), and is suitable for harsh industrial scenarios.

Product composition and I/O card types

1. Core components

I/O carrier: DIN rail installation, carrying all I/O components, providing power distribution and signal bus, divided into two specifications: 8-slot (main carrier) and 2-slot (expansion carrier).

Power supply: Large capacity AC to 24V DC power supply, providing power for on-site equipment and I/O modules.

I/O module: including analog (AI/AO), discrete (DI/DO) and other types, unified packaging form, matched with dedicated terminal blocks to achieve on-site wiring.

Extension cable: Flexible extension of carrier installation location, supporting long-distance deployment.

Terminal blocks: divided into standard type, fuse type, redundant type, and Mass (batch wiring) type, some of which support third-party wiring schemes (such as Phoenix, P+F HiC safety barriers).

2. Main I/O card specifications

(1) Analog Input Card (AI)

Covering current, voltage, and temperature sensor signal acquisition, the key model parameters are as follows:

Card type, channel number, signal type, core parameter redundancy support

AI 4-20mA HART 8 4-20mA (2/4 wire system) accuracy 0.1% range, 16 bit AD, HART transparent transmission, channel optical isolation 1500V DC

AI Plus 4-20mA HART 16 4-20mA (2/4 wire system) accuracy 0.2% range, 16 bit AD, supports batch wiring terminal blocks

RTD input card 8 Pt100/Pt200/Ni120 2/3/4 wire system, 100 μ A excitation, accuracy ± 0.2~3.5 ° C (depending on sensor) No

Thermocouple/mV card 8 B/E/J/K and other thermocouples, mV signal cold junction compensation ± 1 ° C, 16 bit AD, supports open circuit detection

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands