YOKOGAWA EJA110E Diff erential Pressure Transmitter

Signal output: default output 4-20mA DC analog signal, and supports BRAIN/HART digital communication overlay; There are also FOUNDATION Fieldbus, PROFIBUS PA, and 1-5V DC (low-power HART) protocols available.

Additional functions: capable of synchronously measuring static pressure, static pressure data can be displayed on integrated indicators or remotely monitored through communication; Equipped with fast response, remote parameter setting, and self diagnostic functions, some models (except for Fieldbus, PROFIBUS, and low-power models) comply with SIL 2 safety certification, and dual transmitter configuration can meet SIL 3 requirements.

2. Environmental adaptability

Temperature: ambient temperature -40-85 ℃ (-30-80 ℃ with LCD), process temperature -40-120 ℃.

Humidity: 0-100% RH.

Protection level: IP66/IP67, Type 4X.

Pressure resistance: The maximum working pressure (MWP) is 16MPa, and the/HG option can reach 25MPa; Blasting pressure of 69MPa (S material non F range) or 47MPa (other materials/F range).

3. Installation and Connection

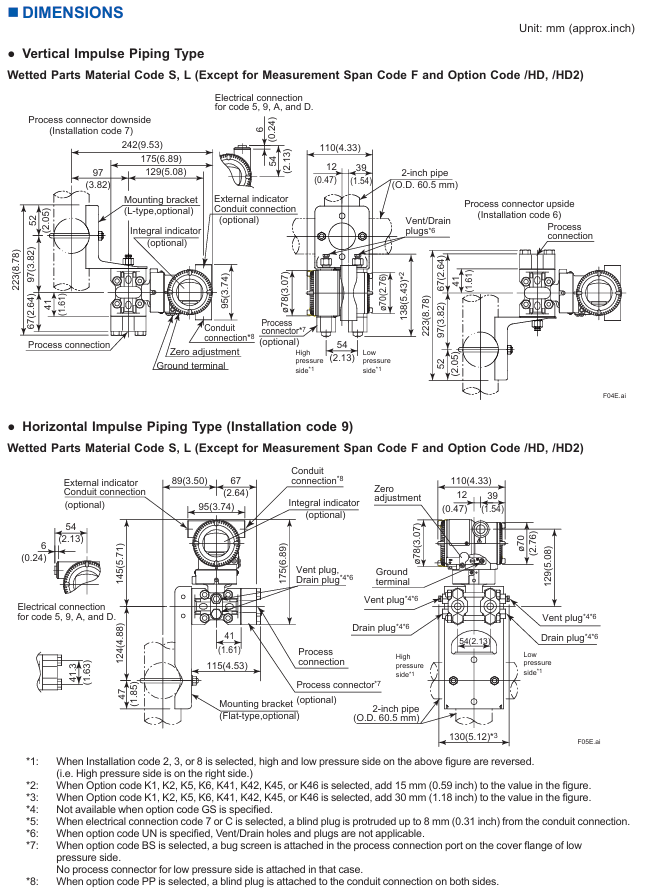

Installation method: Supports vertical pipelines (left high-pressure connection), horizontal pipelines (left/right high-pressure connection), bottom connections, etc., and requires corresponding installation codes (7, 8, 9, U, B, etc.).

Process connection: Optional Rc1/4, Rc1/2, 1/4 NPT, 1/2 NPT and other interfaces, or no connector (flange with internal thread).

Electrical connection: Supports G1/2, 1/2 NPT, M20 and other interfaces, with 1-2 connection ports and blind plugs (optional stainless steel blind plugs).

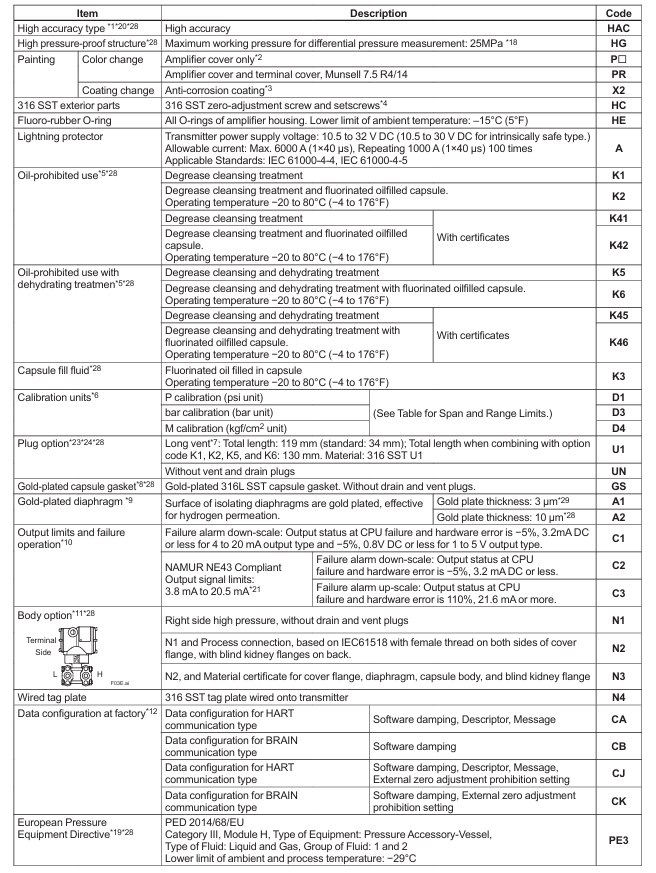

Selection and optional specifications

1. Model suffix code (core selection dimension)

Example explanation of selection dimension code

The output signals D (BRAN), J (HART 5/7), and Q (1-5V HART) determine the communication protocol and signal type

Capsule types F, L, M, H, V determine the range of measurement

Wet end materials S, L, H, M, etc. are suitable for different corrosive media

Explosion proof certification FF1 (FM explosion-proof), KS21 (ATEX intrinsic safety), CF1 (CSA explosion-proof) and other suitable for hazardous environments

2. Key optional functions

High precision (HAC): Improve the accuracy of M/H/V capsules.

High pressure structure (HG): MWP increased to 25MPa.

Lightning protection (A): Maximum withstand current of 6000A (1 × 40 μ s).

Anti corrosion treatment (X2/HC): epoxy coating or 316 stainless steel external parts.

Certificate type (L4/L5/L6/L9): Provide calibration certificates (including traceability, standard list, etc.).

Installation and ordering information

1. Installation points

Size: Different installation methods (vertical/horizontal/bottom/universal flange) correspond to different sizes (unit: mm/inch), please refer to the dimension diagram in the document, for example, the total length of the vertical pipeline type is about 223-256mm.

Wiring: 4-20mA type needs to distinguish between power/output terminals and external indicator terminals; The 1-5V type requires distinguishing between power terminals and signal terminals, and supports 3-4 wire connections.

2. Clear information required for ordering

Model, suffix code, and option code.

Calibration range (LRV/URV, -32000 to 32000, LRV needs to be 0 for square root output) and units (such as kPa, psi).

Output mode (linear/square root) and display mode.

The display scale of the integrated indicator (0-100% or custom range).

HART protocol version (choose 5 or 7 for J code).

Tag (TAG NO: 16/22 characters; Software Tag: 32 characters, HART 7 supports long tags).

Compliance and Reference

Compliance standards: EMC complies with EN 61326-1 Class A, pressure equipment complies with EU 2014/68/EU (PED), RoHS complies with EN IEC 63000.

Reference documents: Fieldbus specifications refer to GS01C31T02-01EN, PROFIBUS PA refers to GS01C31T04-01EN, functional safety data refers to TI01C25A05-01EN/21EN.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands