Honeywell Enhanced Micro TDC 3000 Control System

Wiring points:

All signal cables (video, keyboard, printer, TPLCN, UCN) are connected from the transition panel at the back of the tower, using dedicated cable clamps and shielded crimping.

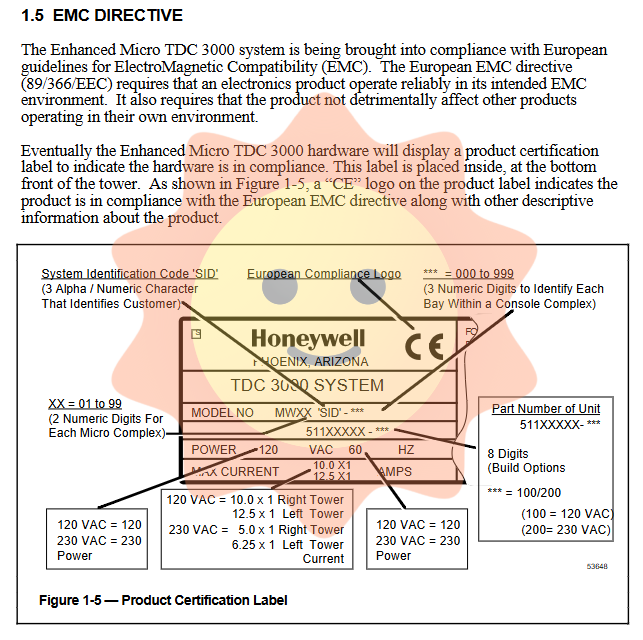

EMC Directive Version: EMC compliant hardware is mandatory for equipment exported to the European Union after 1996. The main differences include: the installation of conductive panels (such as EPDGC, CLIA, TP-485-3) on the I/O board, the use of braided/aluminum foil double shielding for cables, 360 ° conductive wrapping for connector housings, and grounding at both ends of all shielding layers.

UCN process wiring: APM is connected to NIM through UCN (Universal Control Network). The UCN trunk line uses RG-6 coaxial cable, and the branch cable (up to 5 meters long) is introduced into the NIM modulation and demodulation card through the F-type joint on the tower bottom transition panel. The fixed address of the primary NIM is 1, the redundant NIM address is 2, and the address of the PMM module in APM is set to 3 (or 4 when redundant).

System Implementation: Network Configuration, Module Loading, and Data Point Construction

The implementation process of the enhanced Micro TDC 3000 is highly centralized, with most of the preset files already stored in HM volumes.

Network Configuration File (NCF): When the system leaves the factory, NCF.CF is pre-set in the&ASY volume, defining 10 units, area AREA01, node numbers (US: 1,2,8; NIM: 3,4-4; AM: 5; HM: 6; CG: 7), and system parameters (clock source, alarm strategy, volume space, etc.). Users can add CG or EPLCG nodes through online reconfiguration.

Module loading:

US guidance: If HM has automatically guided and>appears on the screen after tower 1 is powered on, press LOAD N and enter UNP to load the universal personality; If HM is not ready, it is necessary to manually load operator personality and NCF/area/button files using&C2 and&C8 cartridge disks.

AM: Select AM node 05 through the system status screen, perform manual loading, select DEFAULT (NET) for both program and data sources, and the status will change to OK after loading.

NIM: Using the same method, select node 03 and automatically restore the preset NIM parameters (network number $NM01N01 $, node allocation THISNIM, loading range NIMandPM) from HM after loading.

APM: Select node 03 on the UCN status screen, execute GRAM LOAD and STORE DATA, and load box point data and I/O configuration from the default source. The I/O card slots 1-4 of the standard double-sided non redundant cabinet are fixed as HLAI, AO, DI, DO, while slots 5-40 are empty.

Optional gateway: CG or EPLCG needs to be loaded from&C8 using empty checkpoints and manually configured with protocol parameters.

Data points: The system has pre-set 1 AM PID point (AM-REG) and 15 APM points (including analog input/output, digital composite, logic, timer, numerical, etc.). The complete parameters are shown in Appendix A. If the cabinet I/O type or slot does not match the preset, the data entity generator (DEB) can be used to modify or create new points.

Custom Features:

Screen editing: The PICS volume already includes sample screens such as KEYLOCK. Users can use Picture Editor to create process flow diagrams, compile them, and store them in the&D01 area.

Free Format Reports: Define the format for printing reports using the Free Format Logs tool.

Button configuration: The blank keys on the left side of the operator keyboard and the PF keys on the engineer keyboard can both be redefined through the BUTTON01 file. The preset file already includes commonly used calls (group display, details, trends, alarm summary, etc.), see Appendix B for details.

CL program: Both the application module and APM support Honeywell Control Language (CL). CL/AM programs need to be loaded into AM through compilers and linkers; CL/APM programs are loaded directly into APM as sequence points.

Regional database: Region AREA01 has been configured with parameters such as 8-point group display, unit trend, system status correlation screen, alarm logs, journals, etc. To install the regional library, you need to specify the path NET>&D01>AREA01 in BUILDER COMMANDS and execute INSTALL ARE.

Operation Guide: Personalized Switching, Keyboard Access, and Monitor Calibration

Personalized loading: Universal personalization allows for the simultaneous use of operational and engineering functions. You can switch between two types of interfaces by pressing CTRL/HELP on the engineer keyboard. If only operational functions are required, the operator's personality can be loaded.

Access level: Due to the lack of a physical key switch in the Micro TDC 3000, the system uses password protected display (SCHEM KEYLOCK) to simulate level three permissions. The default factory password is TDC3000 SUPV (supervisory level) and TDC3000 ENGR (engineer level). Press HELP on the system status screen to bring up the KEYLOCK screen, and enter the password to increase permissions. The password can be modified through the screen editor.

Display adjustment:

IDEK MF-5221 (old model): The analog knob is located below the screen and can adjust brightness, contrast, raster rotation, pillow distortion, vertical/horizontal dimensions, and center.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands