Foxboro ™ I/A Series FBM222 Analog Input Module

Foxboro ™ I/A Series FBM222 Analog Input Module

Product Overview and Core Positioning

FBM222 is a 16 channel highly integrated analog input module with core functionality for Foxboro ™ The I/A Series distributed control system (DCS) collects 4-20mA analog signals on site (supporting two-wire/three wire transmitters), while using HART ® The protocol (digital communication superimposed on 4-20mA signal) enables bidirectional data exchange with on-site devices (such as reading device diagnostic information and configuring parameters). It is positioned as a "high-density, high reliability analog signal+HART digital signal integrated acquisition center", suitable for the needs of batch collection of sensor/transmitter data in industrial scenarios such as petroleum, chemical, and power.

1. Core functions and compatibility

Dual compatibility of signals: All 16 channels support "4-20mA analog signal" and "HART ® Digital signals "can be mixed and connected to different types of on-site devices (without the need for additional hardware switching).

HART communication capability: As a HART host, it supports HART protocol v5/v6/v7 version devices and can execute HART universal commands, common commands, and device specific commands (with Field Device Expert for HART tool), but does not support HART burst mode.

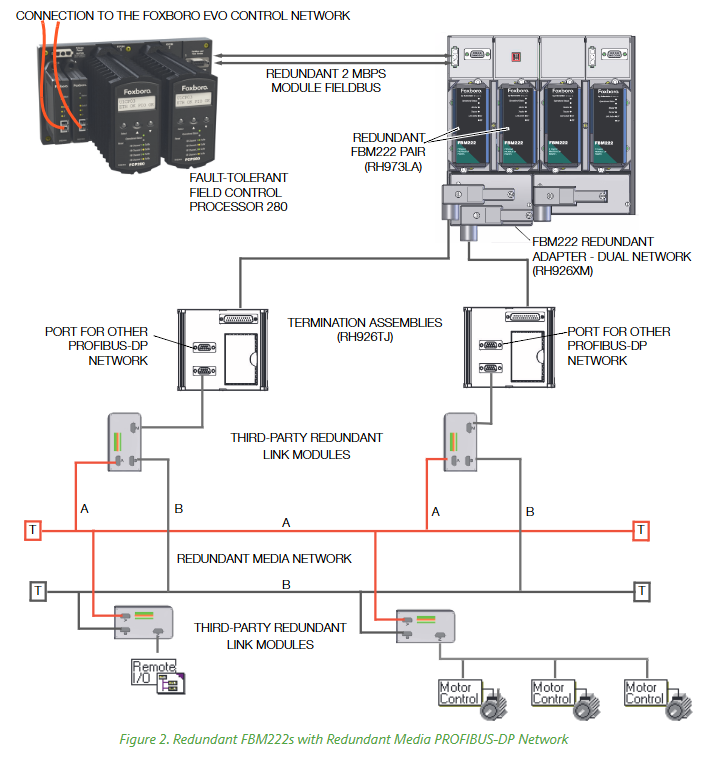

Basic adaptation requirements: It is necessary to use I/A Series software v8.2-v8.8 or Control Core Services (CCS) v9.0 or above, and connect to the Fieldbus communication module (FCM) or control processor (FCP) through a redundant 2Mbps fieldbus to achieve data upload and instruction issuance.

Power supply flexibility: Supports "internal module power supply" (providing 24VDC power supply for two-wire transmitters) or "external independent power supply" (compatible with three wire devices), and signal crosstalk needs to be suppressed through Cable Balun modules when external power is supplied.

Key features and technological advantages

1. Core Features

Specific description of characteristic categories

Full isolation protection achieves triple isolation: 16 channels are isolated from each other, channels are isolated from module logic circuits, and channels are isolated from ground. It can withstand 600VAC common mode voltage for 1 minute (without damage), completely avoiding signal interference and equipment burnout risks.

High precision acquisition adopts Sigma Delta (∑ - Δ) analog-to-digital converter, with a data update cycle of 100ms per channel. The accuracy of analog acquisition meets the industry's high standards, meeting the requirements of process control for real-time and accurate data.

The harsh environment adaptation shell is made of extruded aluminum material, which meets the Class G3 (harsh industrial environment) requirements of ISA S71.04 standard. It can withstand complex scenarios such as dust, humidity fluctuations (5% -95% non condensing), and sudden temperature changes (-20~70 ℃).

Hot swappable and easy to maintain support "with hot swappable", allowing for module replacement without disconnecting field wiring, power supply, or communication bus; The front of the module is equipped with LED indicator lights (running status, bus activity, channel communication status), which can intuitively locate faults.

Communication redundancy ensures access to a redundant 2Mbps fieldbus (A/B dual path), which automatically switches to the backup path in case of a single path failure without communication interruption, ensuring data collection continuity.

2. Special component: Cable Balun module

When multiple channels are powered by an external common power source, a Cable Balun module is required to maintain the balance of the HART communication line and prevent near end crosstalk (this component is not required for internal power supply channels). The core parameters are as follows:

Specific specifications of component information

Model CBM-4

Part number RH903SV

Each module contains 4 Balun units (1 unit corresponds to 1 external power supply circuit), with a maximum increase of 30 Ω in circuit resistance to suppress signal interference

If the hazardous environment adaptation is used in hazardous areas (such as Zone 2), it is necessary to use intrinsic safety barriers (such as MTL 787S+) to limit the energy of the line; External power sources can be connected in parallel with redundant power sources. It is recommended to use capacitors to filter out AC interference

Functional and Performance Specifications

1. Signal and communication parameters

Parameter category specific specifications

HART device compatibility supports HART ® On site devices for protocol v5, v6, and v7 versions

Internal power supply of input resistor (including terminal components): 302 Ω; External power supply: 282 Ω

Internal power supply output 24VDC ± 10%, output impedance 20 Ω (including terminal components), single channel current limit < 37mA (anti overcurrent)

Fieldbus communication redundancy of 2Mbps, bidirectional communication with FCM/FCP, with a maximum communication distance of 1.2km (without repeaters)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands