Honeywell Fusion4 MSC-L Multi Stream Loading Controller

Honeywell Fusion4 MSC-L Loading Controller: A Precise, Safe, and Integrated Trade Handover Preset Control Platform

Introduction

In the fields of petroleum, chemical, and liquefied gas storage and transportation, terminal operation stations are facing increasingly severe operational pressures: increasing throughput, shortening loading and unloading time, eliminating economic losses caused by measurement errors, meeting international legal measurement standards, and strictly controlling safety risks. The Honeywell Enraf Fusion4 Multistream Controller for Loading (hereinafter referred to as Fusion4 MSC-L) was born for this purpose - it is not only a pre installed controller certified for trade handover, but also an intelligent vehicle control platform that integrates high-precision flow control, flexible multi arm management, global explosion-proof certification, and intuitive human-machine interaction. This article is based on Honeywell's official technical manual and provides an in-depth analysis of the system architecture, core algorithms, I/O expansion strategy, and integration capabilities of Fusion4 MSC-L.

System positioning and typical applications

Fusion4 MSC-L is designed specifically for multi channel trade handover loading scenarios. A single controller can manage 1 to 6 loading arms simultaneously, supporting:

Loading and unloading of highway tanker trucks

Loading and unloading of railway tank cars

Aviation refueling

Tank transfer

Ship fuel refueling (marine fuel oil/liquefied gas)

pipeline transportation

Loading and unloading of LPG/LNG tanker trucks

Whether it is rapid loading of a single product, or the need for proportional blending, side flow injection, sequential mixing, and control of internal and external additive injection, MSC-L can achieve precise execution through its flexible formula system (with 300 preset formulas built-in).

Breakthrough ergonomic design

3.1 8-inch WVGA full-color industrial screen

The Fusion4 MSC-L abandons the limitations of traditional monochrome character interfaces and is equipped with an 8-inch, 16:9 aspect ratio, full-color TFT LCD display. The interface adopts a people-oriented icon driven design, abandoning complex menu levels, allowing drivers and operators to operate intuitively without specialized training. The real-time loading status is presented in the form of dynamic progress bars and flow curve graphs, making the single loading process clear at a glance.

3.2 Multilingualism and Global Adaptability

The screen display supports 12 languages, covering:

English (American/British)

Simplified Chinese

Japanese

Thai

French

Spanish

Portuguese

Italian

Dutch

German

Polish

This feature allows MSC-L to be seamlessly deployed in major oil ports, refineries, and storage and transportation hubs around the world without the need for hardware replacement.

3.3 Quick Start and On site Maintenance

The cold start time of the device is less than 1 minute and supports online firmware upgrades. Through local access devices (LAD), maintenance personnel can directly adjust parameters, confirm alarms, and upgrade firmware in hazardous areas without opening explosion-proof enclosures. LAD supports batch import/export of configuration files, reducing the deployment time of multiple controllers from hours to minutes.

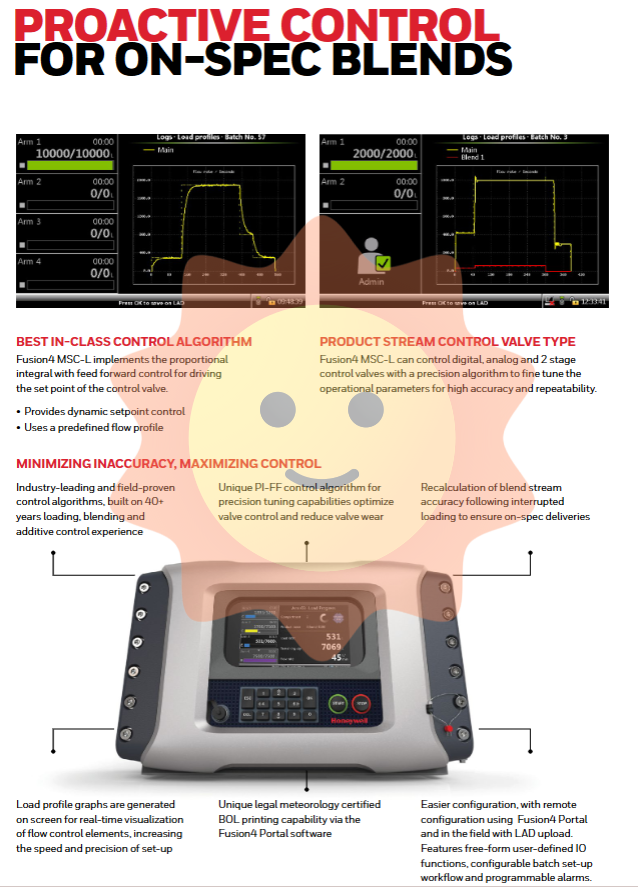

Core control technology: PI-FF and feedforward dynamic setting

4.1 40 years of experience crystallization

The Fusion4 MSC-L adopts the proportional integral plus feedforward (PI-FF) control algorithm, which is derived from Honeywell Enraf's over 40 years of experience in vehicle installation and tuning control. Unlike traditional PID, PI-FF not only provides feedback on current errors, but also actively adjusts valve settings based on predefined flow curves, significantly suppressing overshoot and fluctuations.

4.2 Valve types are fully compatible

The controller can directly drive:

Digital on-off valve (two position type)

Analog control valve (4-20mA or 0-10V)

Two stage control valve (high-speed/low-speed switching)

By drawing real-time loading process curves, engineers can directly observe valve response characteristics and fine tune parameters on the screen, achieving sub milliliter level repeatability accuracy.

4.3 Accuracy self recovery after interruption

When the loading process is interrupted due to reasons such as emergency stop or communication interruption, MSC-L can recalculate the remaining flow and blending ratio to ensure that the final delivered product still meets specifications and avoid the entire batch being scrapped.

4.4 Legal measurement printing

In conjunction with Fusion4 Portal software, the system supports the printing of bills of lading that have been certified by legal metrology, meeting the compliance requirements for international trade handover.

Modular hardware and scalable I/O architecture

The Fusion4 MSC-L adopts a fully modular and backplane design, which connects the HMI motherboard, power function board, and each loading arm backplane through the CAN bus. Its I/O configuration is divided into two series based on license level: MSC-L series (1-3 arms) and MSC-XL series (4-6 arms).

5.1 MSC-L series I/O capability (1-3 arms)

Model Backboard Number CAN PSF CAN ARM Pulse Input ¹ Pulse Output DO-SSR DO-EMR DI-AC DI-DC RTD AI AO RS485 Ethernet

MSC‑L1 1 1 1 12 / 6 2 12 2 0* 0* 0 3 1 5 2

+1 CAN IN‑OUT 1 1 1 12 / 6 2 16 3 1 5 3 7 2 5 2

+2 CAN IN‑OUT 1 1 1 12 / 6 2 20 6 3 0? 6 3? 7? 5 2

*Note: The idle pulse input terminal on the arm card can be configured as a digital input interface.

The specific I/O quantities for each model are shown in the manual table, and this is a comprehensive excerpt.

5.2 MSC-XL series I/O capability (4-6 arms)

The XL series is equipped with 2 loading arm backboards, supporting up to 6 concurrent arms, doubling I/O resources, and providing expansion space for up to 4 additional CAN IN-OUT cards. Taking MSC-XL6+4 CAN IN-OUT as an example, the system can provide:

24/12 high-frequency pulse inputs (10 kHz)

24 pulse outputs

40 solid-state relay outputs (DO-SSR)

12 way electromagnetic relay output (DO-EMR)

40 channels of digital input for communication

60 DC digital inputs

6-way RTD

14 analog inputs

6-channel analog output

7-way RS485 serial port

3 Ethernet ports

This modular expansion strategy allows users to invest accurately based on actual measurement and control points, avoiding resource waste.

Communication and system integration capability

6.1 Multi protocol Embedded Library

Fusion4 MSC-L has a rich built-in communication protocol library, which can be integrated with mainstream host systems without additional programming:

FLEXCONN (Honeywell Enraf Private Protocol)

SLIP+

Modbus RTU

Modbus TCP/IP

FMC SMITH protocol

6.2 Physical Interface

Ethernet: up to 3 10/100 Base-T ports, supporting IEEE 802.3 standard

Serial port: up to 7 isolated RS485 channels, suitable for multi-point instrument and card reader access

6.3 Level 3 System Integration

Level 1: Native integration with Honeywell Expert Terminal Manager (based on Expert PKS) to achieve integrated control from tank area metering to oil dispensing station.

Level 2: Seamless integration with third-party TAS/DCS/PLC through Modbus/LIP+, supporting standard MES/ERP data exchange.

Level 3: Remote centralized monitoring, audit tracking, batch parameter issuance, and bill of lading printing are achieved through the Fusion4 Portal software platform.

Strict environmental adaptability and safety certification

7.1 Global Explosion proof Certification

Fusion4 MSC-L has been certified for use in explosive environments as follows:

Certification System Explosion proof Mark

ATEX II 2 G Ex db [ia] IIB T6 Gb

IECEx Ex db [ia] IIB T6 Gb

FM Class 1 Div 1 Group C&D T6

CSA/CUL Class 1 Div 1 Group C&D T6

CCOE Ex db [ia] IIB T6 Gb

INMETRO Ex db [ia] IIB T6 Gb

The shell is made of anodized aluminum material with a protection level of IP66/NEMA 4X, which can resist high-pressure water gun spray and severe marine atmospheric corrosion.

7.2 Wide temperature operation

Working temperature: -40 ℃ to+65 ℃ (-40 ℉ to+185 ℉)

Storage temperature: -40 ℃ to+85 ℃ (-40 ℉ to+185 ℉)

Humidity: 5% to 95% non condensing

7.3 Electrical Isolation and Safety Design

All I/O channels adopt full isolation technology, comply with the RoHS directive, and eliminate harmful substances such as lead and mercury. The wiring terminals adopt color coding and tool free plug and unplug design to prevent installation errors and shorten on-site wiring time.

Local and remote collaborative operation and maintenance

8.1 Local Access Devices (LAD)

LAD is an inherently safe handheld terminal designed for on-site operations in hazardous areas (Zone 0/Zone 1). Implemented through LAD:

parameter adjustment

Alarm confirmation and reset

Firmware update

Configure upload/download

LAD offers three explosion-proof versions: FM, CSA, ATEX/IECEx, with part numbers 323-1392002/003/004.

8.2 Fusion4 Portal software

Portal is the unified operation and maintenance portal for the Fusion4 series, with the following core functions:

Real time monitoring: The dashboard displays the status, instantaneous flow rate, cumulative measurement, and alarm list of each loading arm.

Remote configuration: Batch modify preset quantities, PID parameters, and communication addresses.

Audit Tracking: Stores 2000 event records and supports export.

Transaction log: 10000 transaction data locally stored, supporting retrieval by time, driver, and license plate.

Bill of lading printing: compliant BOL template, supports LAN/WAN printers.

Supporting ecosystem: from additives to terminal management

9.1 Fusion4 Multiplak Pre Integrated Refueling Station

For frequently used additive injection scenarios, Honeywell offers the Fusion4 Multiplak integrated modular system. It integrates the MSC-A (additive controller) and MONOBLOCK III/II+injection head into an independent bracket, and completes hydraulic and electrical testing before leaving the factory. Users only need to connect the inlet and outlet pipelines and power supply to put it into use, greatly reducing the on-site debugging cycle.

9.2 Experion Terminal Manager(ETM)

ETM is Honeywell's advanced terminal management application for large oil depots, refineries, and chemical terminals, based on the core platform of Expert PKS, integrating:

Ship/Train/Car Dispatch

Inventory Movement Management

Tank area monitoring and leakage prevention

Safety interlock and emergency stop

Fusion4 MSC-L, as the on-site execution layer of ETM, has achieved a complete digital closed-loop process from order placement to loading completion.

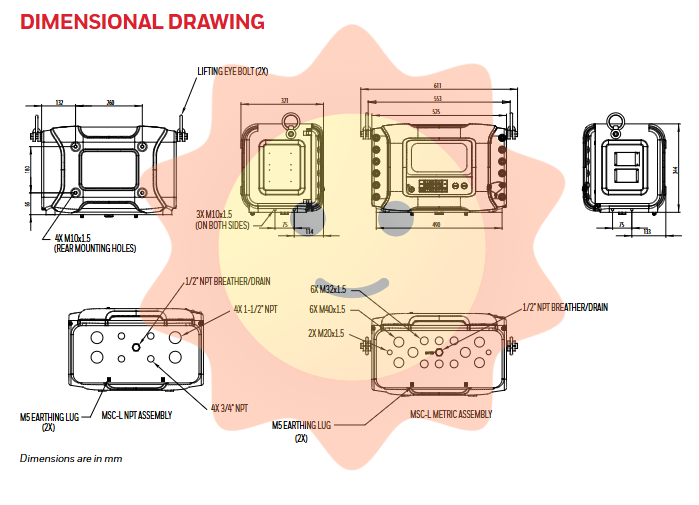

Quick Overview of Technical Specifications

Parameter specifications

Maximum number of loading arms 6

Display screen 8 "WVGA TFT, 16:9, color, LED backlight

Pulse input 24 channels, 10 kHz, configurable as 12 channels of dual pulses

14 analog inputs (maximum)

Analog output 6 channels (maximum)

RTD input 6 channels (maximum)

Digital input 60 DC/12 AC

Digital output 4 channels DC/40 channels EMR/40 channels SSR

Communication interface 3 x Ethernet, 7 x RS485

The protocol supports FlexConn, SLIP+, Modbus RTU/TCP, FMC Smith

Power supply 88-264 Vac

Cable entrance 6 × M40+6 × M32+2 × M20 (metric)

4 x 1/2 "NPT+4 x 3" NPT (US)

Weight approximately 53 kg

Dimensions 525 × 490 × 611 mm (including lifting ring)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands