Honeywell Fusion4 MSC-L Multi Stream Loading Controller

Honeywell Fusion4 MSC-L Loading Controller: A Precise, Safe, and Integrated Trade Handover Preset Control Platform

Introduction

In the fields of petroleum, chemical, and liquefied gas storage and transportation, terminal operation stations are facing increasingly severe operational pressures: increasing throughput, shortening loading and unloading time, eliminating economic losses caused by measurement errors, meeting international legal measurement standards, and strictly controlling safety risks. The Honeywell Enraf Fusion4 Multistream Controller for Loading (hereinafter referred to as Fusion4 MSC-L) was born for this purpose - it is not only a pre installed controller certified for trade handover, but also an intelligent vehicle control platform that integrates high-precision flow control, flexible multi arm management, global explosion-proof certification, and intuitive human-machine interaction. This article is based on Honeywell's official technical manual and provides an in-depth analysis of the system architecture, core algorithms, I/O expansion strategy, and integration capabilities of Fusion4 MSC-L.

System positioning and typical applications

Fusion4 MSC-L is designed specifically for multi channel trade handover loading scenarios. A single controller can manage 1 to 6 loading arms simultaneously, supporting:

Loading and unloading of highway tanker trucks

Loading and unloading of railway tank cars

Aviation refueling

Tank transfer

Ship fuel refueling (marine fuel oil/liquefied gas)

pipeline transportation

Loading and unloading of LPG/LNG tanker trucks

Whether it is rapid loading of a single product, or the need for proportional blending, side flow injection, sequential mixing, and control of internal and external additive injection, MSC-L can achieve precise execution through its flexible formula system (with 300 preset formulas built-in).

Breakthrough ergonomic design

3.1 8-inch WVGA full-color industrial screen

The Fusion4 MSC-L abandons the limitations of traditional monochrome character interfaces and is equipped with an 8-inch, 16:9 aspect ratio, full-color TFT LCD display. The interface adopts a people-oriented icon driven design, abandoning complex menu levels, allowing drivers and operators to operate intuitively without specialized training. The real-time loading status is presented in the form of dynamic progress bars and flow curve graphs, making the single loading process clear at a glance.

3.2 Multilingualism and Global Adaptability

The screen display supports 12 languages, covering:

English (American/British)

Simplified Chinese

Japanese

Thai

French

Spanish

Portuguese

Italian

Dutch

German

Polish

This feature allows MSC-L to be seamlessly deployed in major oil ports, refineries, and storage and transportation hubs around the world without the need for hardware replacement.

3.3 Quick Start and On site Maintenance

The cold start time of the device is less than 1 minute and supports online firmware upgrades. Through local access devices (LAD), maintenance personnel can directly adjust parameters, confirm alarms, and upgrade firmware in hazardous areas without opening explosion-proof enclosures. LAD supports batch import/export of configuration files, reducing the deployment time of multiple controllers from hours to minutes.

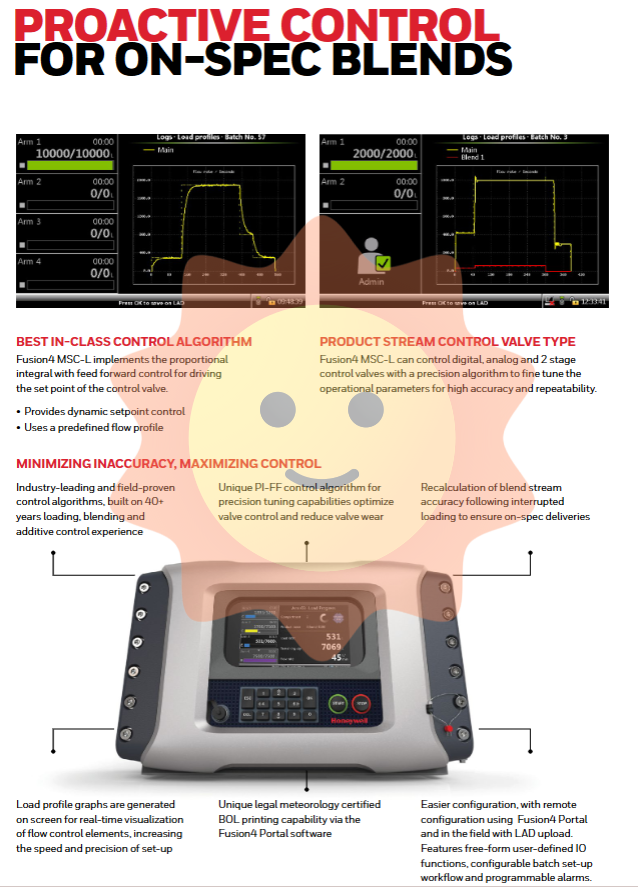

Core control technology: PI-FF and feedforward dynamic setting

4.1 40 years of experience crystallization

The Fusion4 MSC-L adopts the proportional integral plus feedforward (PI-FF) control algorithm, which is derived from Honeywell Enraf's over 40 years of experience in vehicle installation and tuning control. Unlike traditional PID, PI-FF not only provides feedback on current errors, but also actively adjusts valve settings based on predefined flow curves, significantly suppressing overshoot and fluctuations.

4.2 Valve types are fully compatible

The controller can directly drive:

Digital on-off valve (two position type)

Analog control valve (4-20mA or 0-10V)

Two stage control valve (high-speed/low-speed switching)

By drawing real-time loading process curves, engineers can directly observe valve response characteristics and fine tune parameters on the screen, achieving sub milliliter level repeatability accuracy.

4.3 Accuracy self recovery after interruption

When the loading process is interrupted due to reasons such as emergency stop or communication interruption, MSC-L can recalculate the remaining flow and blending ratio to ensure that the final delivered product still meets specifications and avoid the entire batch being scrapped.

4.4 Legal measurement printing

In conjunction with Fusion4 Portal software, the system supports the printing of bills of lading that have been certified by legal metrology, meeting the compliance requirements for international trade handover.

Modular hardware and scalable I/O architecture

The Fusion4 MSC-L adopts a fully modular and backplane design, which connects the HMI motherboard, power function board, and each loading arm backplane through the CAN bus. Its I/O configuration is divided into two series based on license level: MSC-L series (1-3 arms) and MSC-XL series (4-6 arms).

5.1 MSC-L series I/O capability (1-3 arms)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands