SEW MOVIDRIVE Inverter PROFIBUS Interface Configuration and Debugging Guide

SEW MOVIDRIVE ® Full analysis of configuration and debugging of PROFIBUS interface for frequency converter

Safety regulations and system prerequisites

1.1 Security Warning and Target Users

All operations must be carried out by personnel who have received professional training and strictly follow the safety tips in the manual. Warning signs are divided into four levels: "Danger", "Warning", "Caution", and "Prompt", corresponding to situations that may cause serious injury, minor injury, equipment damage, or operational advice. Especially for PROFIBUS networks, which belong to open communication systems, access protection measures must be taken to prevent unauthorized parameter modifications from causing system loss of control or data leakage.

1.2 Usage conditions and documentation matching

MOVIDRIVE ® The frequency converter should be used in designated industrial environments to avoid non applicable situations such as explosion prevention and strong corrosion. This document is a supplement to the product operation manual and must be accompanied by the MOVIDRIVE ® The operation manual and product manual of "Technology Application Frequency Converter" should be used in combination. The latest version of GSD file MOVISUITE ® Both software and sample projects can be downloaded from the SEW-EURODRIVE official website.

PROFIBUS Network Fundamentals and Installation Requirements

2.1 Introduction to PROFIBUS Communication Protocol

PROFIBUS (Process Field Bus) is an international open fieldbus standard that supports master-slave communication architecture. MOVIDRIVE ® As a slave device, the frequency converter supports the PROFIBUS DP-V1 protocol, which supports both periodic process data exchange and non periodic services such as parameter reading and writing, diagnostic alarms.

2.2 Cable laying and EMC specifications

To ensure communication stability, A-type shielded twisted pair cables (compliant with IEC 61158) must be used and the following installation guidelines must be strictly followed:

The shielding layer must be grounded extensively on both sides of the plug to ensure equipotential connection;

Signal cables and power cables (such as motor wires) must be laid separately, preferably in independent cable trays or metal troughs;

Avoid using connectors to extend the bus, and cables should be laid along the grounded metal surface;

The plug should be made of metal casing or metalized casing and tightened with the specified torque.

2.3 Bus Terminal Configuration

The head and tail devices of each PROFIBUS segment must use plugs with integrated terminal resistors and ensure that the terminal resistors are in the "ON" state to avoid communication errors caused by signal reflection.

Hardware connection and address settings

3.1 Engineering Access Interface

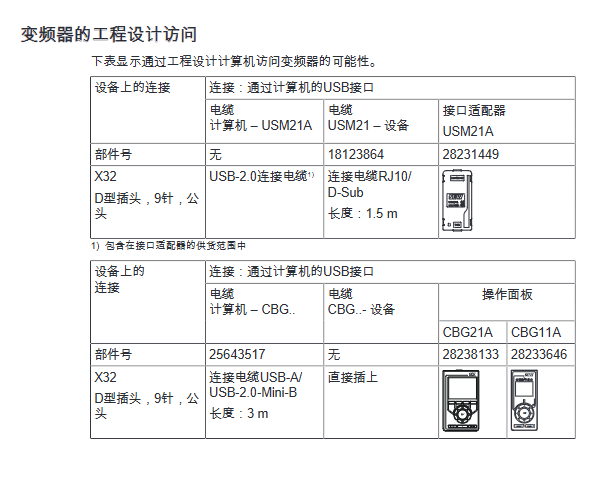

There are two ways to connect the computer and the frequency converter during the debugging phase:

Using the USM21A interface adapter: Connect the computer with a USB-A to USB-B cable, and then connect to the frequency converter with an RJ10/D-Sub cable.

Through the handheld controller CBG11A/CBG21A: directly connected via USB interface for easy on-site debugging.

3.2 PROFIBUS Address Setting

The PROFIBUS address is set through the 8-bit DIP switch on the CFP21A card, supporting a range of 1-125. The address calculation formula is:

Address=SW1 × 1+SW2 × 2+SW3 × 4+SW4 × 8+SW5 × 16+SW6 × 32+SW7 × 64

The default factory address is 4 (SW3=ON, all others OFF). After the address is modified, the frequency converter needs to be restarted to take effect.

Software configuration and device integration

4.1 Equipment Description Document (GSD Document)

The prerequisite for correct configuration is to import the corresponding GSD file (such as SEW-6011. gsd) into the PLC engineering tool. This document describes the communication characteristics, module structure, and parameter interfaces of the frequency converter. It is strictly prohibited to manually modify GSD files, otherwise it may result in abnormal device functionality and loss of manufacturer technical support.

4.2 Process Data and Slot Model

MOVIDRIVE ® The frequency converter adopts a modular slot model to map process data:

Slot 1: Reserved

Slot 2: Process data input/output area, configurable with 5-word (Velocity Drive) or 8-word (Positioning Drive)

Slot 3-5: Expandable configuration, supporting up to 16 process data words

The process data word is directly mapped to the I/O area of the PLC, enabling the issuance of set values and the upload of actual values.

4.3 Hardware Configuration in TIA Portal

The configuration steps in Siemens TIA Portal are as follows:

Install the GSD file and select "SEW-EURODRIVE → MOVI-C MOVIDRIVE" in the hardware directory;

Drag the frequency converter into the PROFIBUS network and set the station address consistent with the DIP switch;

Delete the reserved entry for slot 1 in the device view and add the required process data module starting from slot 2;

Download configuration to PLC.

MOVISUITE ® Parameter Setting and Debugging in

5.1 Network Scanning and Device Identification

After connecting the frequency converter via USB, create a project in MOVISUITE, select the "USB" network type, and perform a scan. The identified devices can be imported into the project and managed in the network view or functional view.

5.2 MOVIKIT ® Application of software modules

To reduce debugging complexity, SEW provides pre configured MOVIKIT ® Software module:

MOVIKIT ® Velocity Drive: Implement speed control and standardize process data interfaces;

MOVIKIT ® Positioning Drive: Supports multiple motion modes such as jog, parameter search, linear/modulus positioning, etc.

Using the MOVIKIT module can significantly reduce debugging time without the need for in-depth understanding of underlying data mapping. The corresponding example projects can be downloaded from the official website.

5.3 Process Data Source Configuration

If the MOVIKIT module is not used, manual configuration of process data sources and data word allocation is required. In the equipment configuration of MOVISUITE, clearly set the value source (such as PROFIBUS) and allocate the actual value feedback channel.

Communication diagnosis and fault handling

6.1 LED status indicator light

BF (Bus Fault): Constant red indicates communication interruption; 2Hz flashing indicates that the device has not been addressed by the main station;

RUN: Green indicates that the bus hardware is normal; The red flashing indicates an address setting error (0 or>125).

6.2 Diagnostic Alarm Function

PROFIBUS supports diagnostic alarms and can be enabled in TIA Portal. When the equipment malfunctions, the fault code and description will be uploaded through diagnostic messages for quick problem identification.

6.3 MOVIKIT Diagnostic Monitor

The built-in diagnostic monitor provides "monitoring mode" and "control mode":

Monitoring mode: Real time viewing of process data exchange status;

Control mode: The set values can be directly issued through a PC for offline testing. Before switching to control mode, it is necessary to ensure that the driver is in a disabled state to prevent accidental actions.

Equipment replacement and data migration

MOVIDRIVE ® The frequency converter supports replaceable memory modules (located in the device slot). After debugging is completed, all parameters, software module configurations, bus settings, and addresses are stored in this module. When replacing the device, simply insert the module into the new device and restart it to restore all settings without the need for reconfiguration, greatly improving maintenance efficiency.

Summary and Best Practice Suggestions

Successfully integrated MOVIDRIVE ® The key to converting a frequency converter to a PROFIBUS network is:

Strictly follow the EMC installation specifications to ensure the stability of the communication physical layer;

Use official GSD files and the latest software tools to avoid compatibility issues;

Make good use of MOVIKIT module to improve standardization and debugging efficiency;

Make full use of diagnostic tools to quickly locate network and equipment failures;

Adopting memory module backup configuration to simplify the device replacement process.

PROFIBUS, as a mature industrial fieldbus, is widely used in MOVIDRIVE ® With the support of frequency converters, high reliability and real-time motion control communication can be achieved. Through the steps and methods described in this article, engineers can systematically complete the entire process from hardware installation to software debugging, providing stable and efficient driving solutions for automation systems.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands