Emerson PAC8000 Remote I/O

Emerson PAC8000 Remote I/O

Product Overview

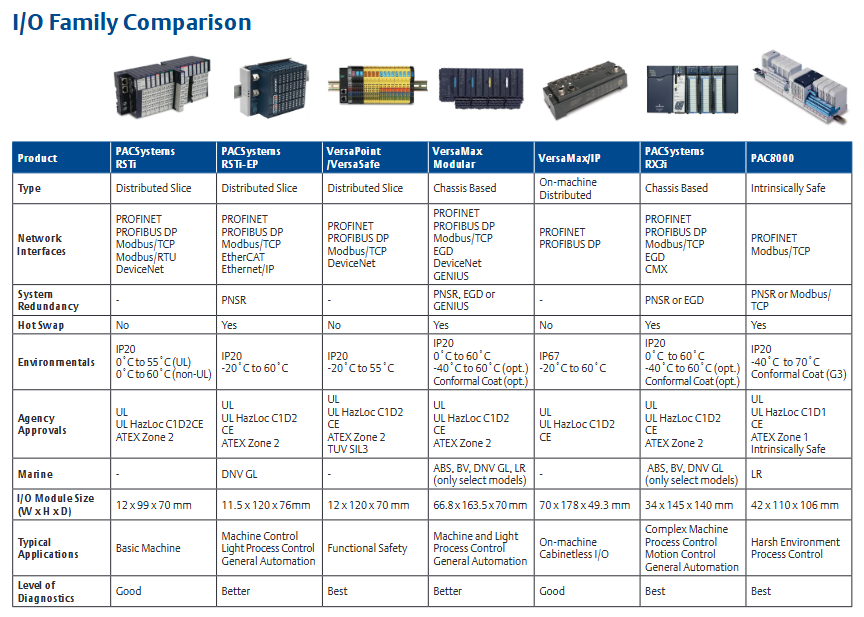

PAC8000 Remote I/O is a fully modular I/O solution suitable for general and hazardous area applications. Based on the carrier system, it supports multiple modules and I/O functions, including intrinsic safety signals. Its open architecture can communicate with various different fieldbuses by selecting appropriate types of bus interface modules (BIM). This product is designed to withstand extreme temperatures, humidity, corrosive substances, impacts, and vibrations, providing full specification performance even in the harshest environments and performing well in ATEX environments. All components can be installed and operated live in Zone 2/Division 2 and ATEX Zone 1 hazardous areas, and I/O includes types that can be directly connected to intrinsic safety (Exi) or increased safety (Exe) field wiring, seamlessly integrated with PACSystems solutions, and connected to RX3i and RSTi EP controllers via PROFINET or Modbus TCP.

Main characteristics

Operation in harsh and hazardous areas: It can operate within the range of -40 ° C to+70 ° C, withstand ISA Level G3 corrosion, 30g impact, and 5g vibration, and is suitable for Class I, Division 2, and Zone 2 hazardous areas. Its I/O module field wiring includes intrinsic safety (Exi) and increased safety (Exe) options, and also supports UL HAZLOC C1D1 and ATEX Zone 1 hazardous areas.

High availability: Supports PROFINET system redundancy (PNSR), enabling synchronized independent controllers to serve I/O and seamlessly transition from active controllers to backup controllers. Controllers can be up to 10 kilometers apart and can handle physical interrupts.

Rich I/O modules: In addition to analog and digital I/O, there are multiple modules to choose from, including options for low-level instruments, AC power supply, and intrinsic safety signals. There are 4, 8, 16, and 32 channel modules, and all modules provide comprehensive diagnostic information.

Easy troubleshooting and machine setup: PAC8000 I/O can be easily configured using the integrated PAC Machine Edition (PME) software. If PROFINET is used, configuring through GSDML files is even simpler. PME software is compatible with all PACSystems CPUs, requiring only one tool for small to large applications and simplifying HMI development.

HART support: PAC8000 Modbus EBIM can directly provide HART data to Emerson's Asset Management System (AMS), allowing remote configuration and access to on-site instrument diagnostic information. It can also obtain HART data for process control applications. HART devices can be selected for routine status monitoring, and alarms can be issued when the status changes, reducing debugging time, downtime, and maintenance costs.

Specification parameters

Installation format: DIN rail.

Network interfaces: PROFINET, Modbus/TCP.

Gateway/Bridge: HART.

Network redundancy: MRP, dual LAN.

System redundancy: PNSR or Modbus/TCP.

I/O redundancy: Dual redundancy.

Media support: Copper cables and multimode optical fibers.

Media connectors: 2 RJ45 or 2 SFP.

I/O type: 24 VDC, 115/230 VAC input, 2-60 VDC, 20-265 VAC output, analog quantity RTD、 Thermocouple.

Specialized modules: pulse testing (24 VDC), pulse input, sequence of events (SoE) input, ASH detector.

Isolation: Galvanic isolation, DI, DO, AI, AO are all isolated.

Hot swappable: supported.

Environmental parameters: IP20 protection level, operating temperature from -40 ° C to 70 ° C, with normal coating, resistant to ISA Level G3 corrosion, able to withstand 30g impact and 5g vibration.

Institutional certification: UL, UL HAZLOC C1D1, CE, ATEX Zone 1, intrinsic safety certification, as well as classification society certification (such as Lloyd's Register).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands