Emerson PR6423 8mm eddy current sensor

Emerson PR6423 8mm eddy current sensor

The Emerson PR6423 8mm eddy current sensor is a non-contact industrial sensor designed specifically for key rotating machinery such as steam turbines, gas turbines, water turbines, compressors, gearboxes, pumps, and fans. Its core function is to accurately measure the radial/axial dynamic displacement, position, eccentricity, and speed of the shaft, providing reliable data support for equipment status monitoring and fault warning. It is suitable for high-precision monitoring of rotating machinery in the field of industrial automation.

Core performance parameters

1. Measurement ability

Linear measurement range: 2mm (80 mil), initial air gap (installation reference gap) is 0.5mm (20 mil), ensuring stable data collection within the common displacement range of rotating machinery.

Incremental Scale Factor (ISF): Compliant with ISO standards, 8V/mm (203.2mV/mil), with an error of ± 5% within the temperature range of 0-45 ° C (32-113 ° F), ensuring measurement accuracy under different operating conditions.

Linearity deviation: Within the temperature range of 0-45 ° C (32-113 ° F), the deviation from the best fitted line is ± 0.025mm (± 1 mil), indicating excellent data linearity and reducing measurement errors.

Measurement target requirements: The minimum shaft diameter is 25mm (0.79 inches), and the default target material is 42CrMo4 (corresponding to AISI/SAE 4140) ferromagnetic steel. Other materials can be customized as needed.

2. Environmental and protective characteristics

Protection level: IP66 (compliant with IEC 60529 standard), can effectively prevent dust, strong water spray, and adapt to complex environments in industrial sites.

Temperature adaptability:

Sensor (including 1-meter cable): Operating temperature -35~+180 ° C (-31~356 ° F), resistant to high temperature conditions;

Cable and connector: Operating temperature -35~+150 ° C (-31~302 ° F), matching the overall temperature resistance range of the sensor.

Material selection:

Sensor probe: PEEK polyetheretherketone (resistant to high temperature and chemical corrosion);

Shell: stainless steel (high-strength, rust resistant);

Cable: polytetrafluoroethylene (PTFE, high and low temperature resistance, good insulation);

Connector: Nickel plated brass (low contact resistance, anti-oxidation).

Weight: The sensor (including a 1-meter cable) weighs approximately 100 grams (3.53 ounces), and its lightweight design makes it easy to install on mechanical structures with limited space.

Compliance certification and adaptation to hazardous areas

1. General compliance

CE certification: Complies with the 2014/30/EU (EN 61326-1, Electromagnetic Compatibility), 2014/34/EU (ATEX Explosion proof), 2011/65/EU (RoHS Environmental Protection) directives, and meets European market access requirements.

Basic explosion-proof standards: comply with ATEX and IEC Ex EN 60079-0 (General Requirements for Equipment) and EN 60079-11 (Intrinsic Safety Equipment) standards, providing basic protection for use in hazardous areas.

2. Hazardous area certification (requires cooperation with converters)

The classification of hazardous areas for sensors depends on the accompanying converter (refer to the converter document for details), and their own temperature classification is as follows:

Explosion proof type, temperature rating, upper limit of ambient temperature (Ta)

Intrinsic safety (ia) T6 ≤ 64 ° C

T4 ≤114°C

T3 ≤160°C

No spark (nA) T6 ≤ 64 ° C

T4 ≤114°C

T3 ≤160°C

Structural dimensions and installation design

1. Two installation types

The sensor offers two structures: standard installation (PR6423/xxx xxx) and reverse installation (PR6423/xxxR xxx). The core size parameters are as follows:

Installation type Key dimensions (mm/inch)

Standard Installation - Shell Thread: M10 × 1 or 3/8-24UNF

-Wrench size: M10 thread with SW 11mm, 3/8-24UNF with SW 7/16 inch

-Standard cable diameter: 2.8mm (0.110 inches), minimum bending radius 25mm (0.984 inches)

-Armored cable diameter: 6mm (0.236 inches), minimum bending radius 35mm (1.378 inches)

The threads, wrenches, and cable sizes for reverse installation and standard installation are the same, with only the installation direction and shell layout different, to meet the installation space requirements of specific mechanical structures

2. Cables and connectors

Cable configuration: An adapter plug can be optionally selected after a 1-meter cable, with a cable length tolerance of 0~+10%, and supports customization of different lengths (such as 8.0m, 9.0m, 10.0m, etc.).

Connector type: The default configuration is a 11.0mm (0.433 inch) diameter Lemo male connector, or an open cable end (without connector) can be selected to meet the interface requirements of different monitoring systems.

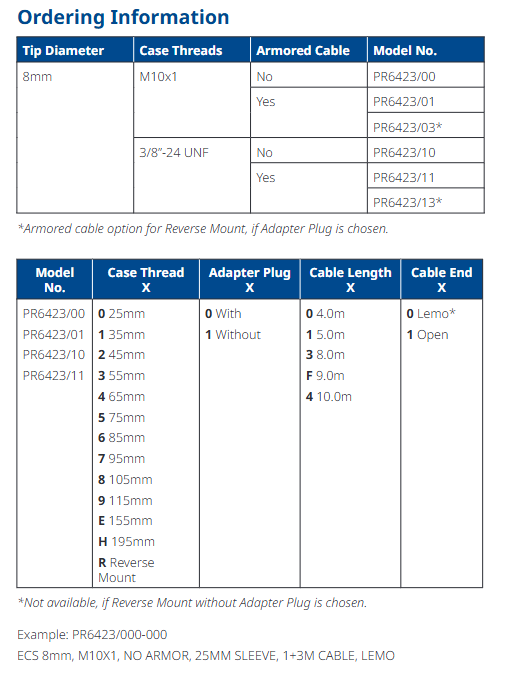

Model selection and special versions

1. Standard model selection (core parameter combination)

Is the diameter of the probe casing threaded with armor cable model

8mm M10 × 1 No PR6423/00

It's PR6423/01

Yes (reverse installation, requires adapter plug) PR6423/03*

3/8 "-24 UNF No PR6423/10

It's PR6423/11

Yes (reverse installation, requires adapter plug) PR6423/13*

*Note: Models with "*" are only suitable for reverse installation with adapter plugs, and reverse installation without adapter plugs is not optional.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA