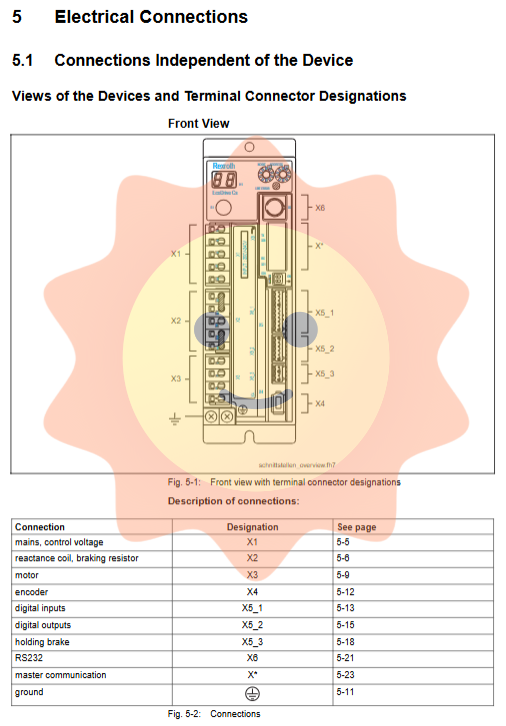

REXROTH EcoDrive Cs series AC servo drive system

5.2 Control Circuit and Safety Interlocking

The "Ready to Run" (Bb) relay contact (normally open) output by the driver is a prerequisite for controlling the main contactor to close. This contact opens when there is a loss of control voltage, emergency stop activation, or driver failure. The emergency stop signal should be directly applied to the enable circuit and should not be removed from behind the Bb contact. When designing an emergency stop circuit, it is necessary to consider the series connection of all drive Bb contacts, as well as the load capacity and power-off delay of the contactors.

5.3 Control Cabinet Planning

Heat dissipation and layout: The total heat generation inside the control cabinet must be calculated to ensure that the inlet air temperature does not exceed the allowable value of the driver. Cooling units can be used, but attention should be paid to preventing condensed water droplets from falling or splashing onto electronic devices, and the temperature should be set reasonably to avoid condensation caused by the temperature inside the cabinet being lower than the ambient temperature.

Wiring specifications: Strong current (power supply, motor wires) and weak current (signal, encoder wires) should be laid separately, with a minimum distance of 100mm or separated by metal partitions. The recommended layout of cable trays helps optimize electromagnetic compatibility (EMC).

EMC measures: To meet electromagnetic compatibility requirements, recommended main power filters (such as NFE/NFD series) should be used, and the folding ferrite core in the attachment (installed near the interface) should be used for signal lines.

6. In depth analysis of MSM series servo motors

The motor offers four frame sizes: MSM020B (100W), MSM030B (200W), MSM030C (400W), and MSM040B (750W), each with/without a brake, incremental/absolute encoder, and optical axis/keyway combination.

6.1 Key Technical Parameters

Thermal performance and working system: The motor data is based on an ambient temperature of 40 ° C and a winding temperature rise of 80K (enclosure IP65). Following the S1 (continuous working system) or S6 (intermittent working system) standards of EN 60034-1, key parameters such as continuous stall torque (Mdn), peak torque (Mmax), and rated speed (nN) are defined.

Shaft and bearing loads: The manual provides detailed allowable radial and axial force data. The rated life of the bearing L10h is 20000 hours when the load does not exceed the limit. Exceeding the radial force will shorten the bearing life in a cubic relationship.

Protection level and installation: The protection level of the motor body is IP65 (when the cable joint is correctly installed), and the shaft extension is IP40. The allowed installation positions include flange installation (IM B5) and shaft extension facing downwards (IM V1) or upwards (IM V3). Tighten the installation screws with the specified torque.

6.2 Encoder System

Incremental encoder: Provides 2500 sine wave signals per revolution (multiplied by 4 to 10000 pulses) with zero marks. Location information lost after power outage.

Absolute encoder: Single cycle resolution of 17 bits (131072 pulses/rev), multi cycle range of 16 bits (65536 cycles). It is necessary to rely on the backup battery inside the drive (Attachment SUP-E03-DKC * CS-BATTY) to maintain multiple cycles of data during power outages. When the battery level is low, the driver will report fault F248. The battery life is positively correlated with the power on time of the drive, and battery replacement needs to be completed within a limited backup time (about 13 minutes for a new battery).

6.3 Maintain the brake

It is of the "power-off clamping" type. Control its on/off timing by the driver. Important note: This brake is designed for static holding, not dynamic braking. Frequent use of shafts in braking motion can lead to premature wear (with a designed lifespan of approximately 3000 motor revolutions in the closed state). Personnel safety cannot rely solely on motor brakes.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA