REXROTH EcoDrive Cs series AC servo drive system

3. Detailed explanation of driving controller technical data

3.1 Mechanical and Environmental Data

The drive controller is designed specifically for installation in control cabinets, with a protection level of IP20. Its rated data environmental conditions are: ambient temperature from 0 to+40 ° C, installation altitude ≤ 1000 meters. The maximum allowable ambient temperature can reach+55 ° C (requiring derating operation), with a maximum installation altitude of 2000 meters. The storage and transportation temperature range is -20 to+80 ° C. Attention should be paid to natural convection cooling, and the longitudinal axis should be consistent with the convection direction during installation. The back should be in full contact with the installation plate and maintain a minimum distance from other components (40mm above, 10mm on the side, and 100mm below).

3.2 Electrical and Performance Data

The power input supports single-phase (1 x 200-240V AC) or three-phase (3 x 200-240V AC) connections. For 750W equipment, three-phase connection is strongly recommended as single-phase operation can significantly shorten the service life and lead to performance degradation.

The manual provides detailed input/output current, power loss, DC bus data, and internal braking resistor parameters. The key "derating" information clearly states that the continuous output capability of the driver and motor needs to decrease according to the curve under the following conditions:

Installation at an altitude exceeding 1000 meters.

The ambient temperature exceeds 40 ° C (with a decrease of approximately 2% for every 1 ° C increase).

Use internal braking resistors (only applicable to 200W and 400W models). At this point, full power can be restored by removing and connecting external braking resistors through jumper wires.

The 750W model uses single-phase power supply.

The control voltage (L1C/L2C of X1 interface) is also 200-240V AC, which is converted internally by the driver to the required voltage. The front panel includes a diagnostic display (H1), a reset/function button (S1), and two ten digit dip switches (S2, S3) for setting the driver address (1-99).

4. Depth analysis of electrical connections

4.1 General Interface Description

All models have the following core interfaces (X1 to X6):

X1 (Power and Control Voltage): Connect the main power supply (L1, L2, L3) and control voltage (L1C, L2C). The connection must use 0.75-2 mm ² twisted wire.

X2 (additional reactor and braking resistor): Connecting an external reactor can increase the power of the continuous DC bus; Connecting external braking resistors (RB1, RB2) can avoid derating when using internal resistors. If external resistors are not used, RB2 and RB3 must be short circuited with jumper wires.

X3 (motor connection): Connect servo motors (U, V, W, PE). It is necessary to use Rexroth original motor cables or certified cables, with a maximum length of 40 meters, otherwise it may result in the system warranty being invalidated.

X4 (Encoder): Provides power (5V, 0V) and signal (PS+/PS -) interfaces for the motor encoder, and includes terminals for backup batteries (if used) for the absolute encoder.

X5_1/X5_2 (digital input/output): Provides 7 configurable digital inputs and 3 configurable digital outputs (including a pair of "ready to run" relay contacts Bb). Both input and output are optocoupler isolated.

X5_3 (holding brake): Control the motor brake (BR+/BR -) and provide its external 24V power input. The brake power supply must be supplied externally, and the brake power supply of multiple drivers should be connected in a star topology, and serial connection is prohibited.

X6 (RS232): Used for debugging, parameter setting, and diagnosis through PC software (such as DriveTop). Only supports point-to-point connections, with a maximum distance of 15 meters.

4.2 Equipment related interfaces

According to the selected basic device (DKC10.3 series) and the inserted Master Communication Card, different terminal device models are formed:

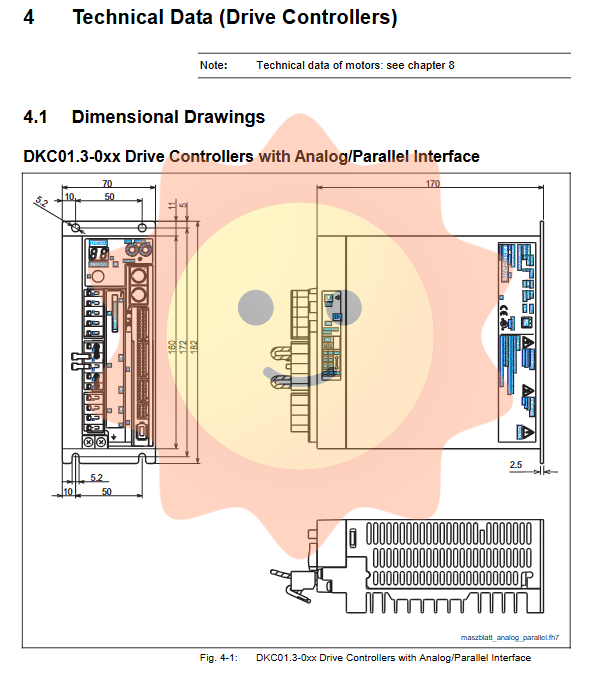

DKC01.3: Analog/Parallel Interface. Additional X5_4 (analog/digital I/O) and X7 (incremental/absolute encoder simulation output) interfaces are provided.

DKC02.3: Integrated SERCOS interface. Connected through fiber optic cables, the front panel dip switch can adjust the light emission power to accommodate different lengths of optical fibers (plastic fiber up to 50 meters, glass fiber up to 500 meters).

DKC03.3: Provide PROFIBUS-DP interface (9-pin D-Sub) by inserting ECM01.1-PB01 card.

DKC06.3/DKC16.3: Provides DeviceNet interface by inserting ECM01.1-DN01 or ECM01.1-DN02 card, with the difference being the connector type (COMBICON or sealed micro).

DKC05.3: Provide CANopen interface (9-pin D-Sub) by inserting ECM01.1-CN01 card.

The main communication card can be installed or replaced on site, and the operation needs to be carried out after power failure.

5. Key points of power connection and control cabinet design

5.1 Main power connection

The driver must be permanently connected to the power grid. When the grid voltage is higher than 240V, an autotransformer or isolation transformer must be used for voltage reduction. The manual provides detailed calculations of surge characteristics and grid side phase currents for different types of equipment, and guides the selection of main contactors (K1) and fuses (Q1) accordingly. To reduce the total surge current caused by multiple drivers being powered on simultaneously, SUP-E05-DKC * CS-SURGEP accessories (including NTC thermistor) can be selected for 100W/200W/400W devices. For 400W equipment, the maximum load power when using this accessory should be limited to 70%.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA