Yokogawa SC200 Intelligent Two Wire Conductivity Transmitter System (IM12D08B01-01E)

Yokogawa SC200 Intelligent Two Wire Conductivity Transmitter System (IM12D08B01-01E)

System positioning and core composition

1. System positioning

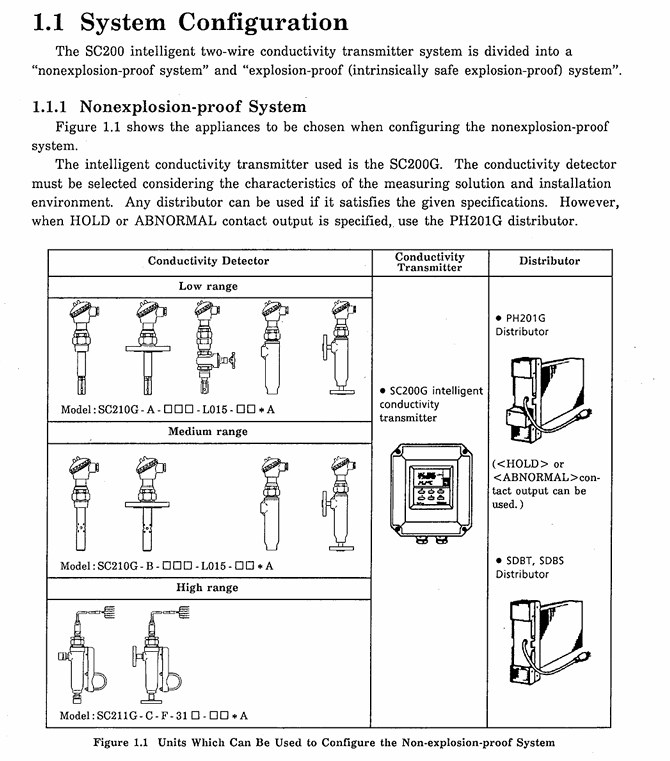

The SC200 system is an intelligent conductivity measurement solution based on microprocessors, which achieves continuous online measurement of solution conductivity through a combination of "transmitter+detector+distributor". It can convert the measured value into conductivity at a reference temperature based on temperature compensation, and support fault diagnosis and signal output control, meeting the measurement needs of ordinary industrial environments and hazardous environments (including explosive gases).

2. Core components

The system consists of three core components, each with clear functions and classifications:

Component type, specific model/classification, core functions

Conductivity detector - SC210G (2-electrode type):

-SC210G-A (low range, electrode constant 0.05 cm ⁻¹)

-SC210G-B (medium range, electrode constant 5 cm ⁻¹)

-SC211G-C (4-electrode type, high range, electrode constant 10 cm ⁻¹) contact measurement solution conductivity, built-in temperature sensor (thermistor for SC210G, Pt1000 for SC211G) for temperature compensation; Supports direct insertion (screw/flange) and flow-through (pipe/flange) installation.

Intelligent Conductivity Transmitter - SC200G (Non Explosion proof Type)

-SC200S (intrinsic safety explosion-proof type) receives the conductivity and temperature signals of the detector, and outputs 4-20 mA DC analog signals after processing; Support digital display, parameter setting, and self diagnosis; Explosion proof type needs to be used in conjunction with safety barriers.

Distributor/Safety Barrier - Distributor: PH201G (supporting HOLD/fault contact output), SDBT/SDBS (universal type)

-Safety Barrier: BARD400 (for intrinsically safe explosion-proof systems) provides power to the transmitter, receives 4-20 mA signals, converts them to 1-5 V DC, and outputs them to the recorder; Safety barriers are used to limit the energy of circuits in hazardous environments and prevent explosions.

Detailed explanation of technical specifications

1. Specification of conductivity detector

(1) Basic parameters

Model measurement range electrode constant contact material (sensor) measurement temperature range measurement pressure range protection level

SC210G-A 0~200 μ S/cm 0.05 cm ⁻¹ SUS316, polytetrafluoroethylene resin, fluororubber 0~105 ℃ (PP bracket 100 ℃) 10 kgf/cm ² (PP bracket 5 kgf/cm ²) IP65 (NEMA 4)

SC210G-B 200 μ S/cm~20 mS/cm 5 cm ⁻¹ Platinum, glass SUS316、 Fluororubber with SC210G-A and SC210G-A IP65 (NEMA 4)

SC211G-C 1 mS/cm~1 S/cm 10 cm ⁻¹ Platinum, glass, polyvinylidene fluoride resin, fluororubber 0~80 ℃ 2 kgf/cm ² Rain proof (JIS C0920)

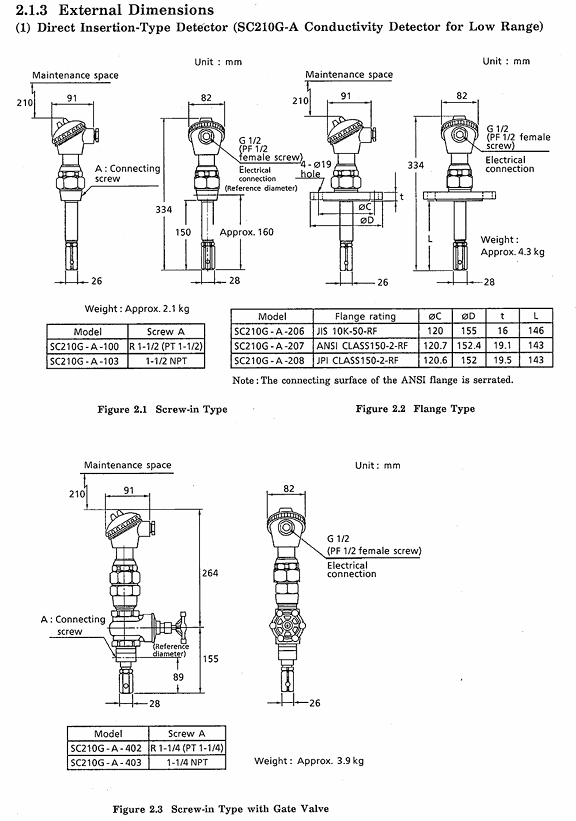

(2) Installation and Interface

Direct insertion type: supports Rc 1-1/2 (PT thread), 1-1/2 NPT thread, or JIS 10K-50-RF, ANSI CLASS 150-2-RF flange;

Flow type: The bracket material is divided into SCS14 (stainless steel) and PP (polypropylene), and the interface is Rc 1/2, 1/2 NPT thread, or JIS 10K-15-RF/FF, ANSI CLASS 150-1/2-RF/FF flange.

2. Smart transmitter specifications

(1) Basic parameters

Parameter category specification details

Measurement and output conductivity display range 0~1999 mS/cm, output signal 4~20 mA DC (linear/line approximation/reverse output), maximum cable length 2000m (non explosion proof)/700m (explosion proof);

The temperature compensation reference temperature is adjustable from 0 to 100 ℃, and the compensation coefficient is adjustable from -10% to+10%/℃. It supports NaCl solution characteristic compensation or custom solution characteristic compensation;

Environmental adaptability: working temperature -10~+55 ℃, storage temperature -30~+70 ℃, humidity 10~100% RH (non condensing); The shell material is cast aluminum (polyurethane baked paint) with a protection level of IP65;

Accuracy and repeatability of conductivity measurement accuracy ± 1% range (1 μ S/cm~2 S/cm), ± 0.02 μ S/cm (0~1 μ S/cm), repeatability ± 0.5% range;

The self diagnostic function supports diagnosis of temperature exceeding limits, conductivity exceeding limits, electrode contamination, temperature coefficient errors, circuit faults, etc. When a fault occurs, it outputs 22.0 mA (when the burnout function is turned on);

(2) Explosion proof specification (SC200S)

Explosion proof type: Intrinsic safety type (Ex ia IIC), to be used in conjunction with BARD400 safety barriers;

Environmental restrictions: Installation height ≤ 1000m, humidity 45~85% RH, prohibited from installation in Zone 0 hazardous environment;

Circuit parameters: Cable inductance ≤ 2.2 mH, capacitance ≤ 35 nF, ensuring no contact between intrinsic safety circuits and non intrinsic safety circuits.

Installation and wiring process

1. Installation of conductivity detector

(1) Preparation before installation

Site selection requirements: easy to maintain, measuring solution temperature/pressure in accordance with specifications, no bubbles, stable liquid level;

Interface preparation: Direct insertion type requires processing of threaded/flange holes that meet specifications (electrode insertion depth ≥ 60mm); The flow type (PP bracket) requires the installation of a nominal 50A (outer diameter 60.5mm) mounting pipe, which can be installed vertically or horizontally.

(2) Installation steps

Direct insertion type: thread type wrapped with sealing tape and screwed into the interface, flange type needs to add gaskets and evenly tighten 4 bolts;

Flow type: fixed to the installation pipe or wall, adjust the direction of the terminal connection port (can rotate by loosening the union nut);

Pipeline connection: Use rigid vinyl chloride pipes (nominal 16) or PP pipes for PP supports, and SUS304/316 pipes (nominal 15) for SCS14 supports. The recommended flow rate is ≤ 20 L/min to avoid the mixing of bubbles.

2. Installation and wiring of transmitters

(1) Installation method

Pipeline installation: fixed to a nominal 50A pipeline (vertical/horizontal) using a dedicated bracket;

Panel installation: The panel opening size is 156 × 121 mm (tolerance+1.1mm), fixed with panel brackets;

Wall installation: Process 3 M8 threaded holes on the wall with a spacing of 70mm, and fix them with wall brackets.

(2) Wiring specifications

Requirements and steps for wiring types

Detector specific cable - SC210G (2 electrodes): 3/5/10m dedicated cable, connecting transmitter terminals 11 (T1), 12 (T2), 13 (C1), 14 (C2);

-SC211G (4 electrodes): 5.5/10m cable with connector, directly inserted into the detector interface, with the other end connected to transmitter terminals 11-16;

2-core shielded cable (outer diameter 6-12mm) is used for transmitting signal cables, with a maximum length of 2000m for non explosion proof systems and 700m for explosion proof systems. The shielding layer is connected to the safety barrier grounding terminal (explosion-proof) or the transmitter grounding terminal (non explosion-proof), with a grounding resistance of ≤ 10 Ω;

Grounding Wiring Non Explosion proof System: The M4 grounding terminal at the bottom of the transmitter is grounded with a wire of ≥ 2 mm ² (JIS Class 1 grounding, resistance ≤ 100 Ω); Explosion proof system: Only grounded through safety barriers, the transmitter is not grounded separately.

Operation and parameter settings

1. Operational hierarchy and mode

The system operation is divided into three levels, with clear functions and permissions at each level:

Operational hierarchy, permission scope, core mode/function

Operational level daily monitoring and basic operations (no need to open the cover) - Measurement mode: display conductivity, temperature, output current;

-Calibration mode: Perform standard solution calibration;

-Display selection: Switch auxiliary data such as temperature, output value, electrode constant, etc;

-Signal Hold: Turn on/off signal hold (requires setting level permission).

Parameter configuration for level adaptation measurement scenarios (requires lid opening operation) - Output range: Set the conductivity range corresponding to 4mA/20mA (4mA value should be less than 60% x 20mA value);

-Maintain parameters: choose to maintain "previous value" or "fixed value" (fixed value 4~20mA adjustable);

-Temperature compensation: Choose NaCl characteristics or custom compensation (input conductivity at reference temperature).

Service level system underlying configuration (password required, only for initial startup or maintenance) - CODE 01: Select temperature sensor type (Pt1000/Ni100/NTC) and temperature unit (℃/℉);

-CODE 02: Set reference temperature (0~100 ℃);

-CODE 03: Select output characteristics (linear/polyline);

-CODE 05: Input electrode constant (including fine adjustment ± 19.99%);

-CODE 07: Select electrode type (2 electrodes/4 electrodes);

-CODE 09: Enable/disable fault burnout function (output 22mA in case of fault).

2. Key operational procedures

(1) Standard solution calibration (operational level)

Enter calibration mode (MEASURE → CAL → YES), immerse the detector electrode in a NaCl standard solution with known conductivity (concentration close to the upper limit of the range, temperature close to the reference temperature);

After the display stabilizes, press the YES key to record the current measurement value;

Enter the actual conductivity of the standard solution at the reference temperature and press the ENT key to complete the calibration;

If the deviation between the calibrated electrode constant and the input value of service level CODE 05 is greater than 20%, Err.3 will be displayed, and the concentration of the standard solution needs to be checked or the electrode needs to be replaced.

(2) Temperature compensation setting (setting level)

Enter temperature compensation mode (Setting → Temperature → YES);

Choose compensation method: NaCl characteristics (default) or custom characteristics (*%);

If customized, adjust the solution temperature to the reference temperature, read the current conductivity and input it, and the system will automatically calculate the compensation coefficient (-10~+10%/℃);

If the compensation coefficient is known, it can be directly input in the service level CODE 14, with priority higher than the calculated value at the setting level.

Maintenance and troubleshooting

1. Regular maintenance

(1) Detector maintenance

Electrode cleaning:

Low/medium range (SC210G): Wipe the electrode surface with a thin rod wrapped in degreasing cotton to avoid scratches;

High range (SC211G): Hot water+detergent is used for ordinary pollution, 5-10% dilute hydrochloric acid is used for lime/hydroxide, and sodium hypochlorite solution is used for algae (mixing hydrochloric acid with sodium hypochlorite is prohibited);

Cleaning cycle: Determine based on the degree of solution contamination. Low range (<200 μ S/cm) may not be cleaned for a long time, while high range (>200 μ S/cm) requires regular inspection.

O-ring replacement: The sealing O-ring (located at the union nut/fixing screw) needs to be checked regularly, and it is recommended to replace it every 6 months in high-temperature solution scenarios to avoid solution leakage.

(2) Transmitter maintenance

Transparent window (polycarbonate material): Clean with a soft cloth or neutral detergent, and do not use organic solvents;

Data backup: After setting the parameters, it is recommended to record key data (electrode constant, reference temperature, compensation coefficient) to avoid power loss.

2. Troubleshooting

The system outputs error codes through self diagnosis. Common faults and their solutions are as follows:

Error code, fault cause, solution measures

Err.1 electrode polarization (pollution, wear, corrosion) cleaning electrode; If the error persists after cleaning, replace the electrode assembly.

Err.2 temperature coefficient calculation abnormality (incorrect reference temperature conductivity input by setting stage). Re measure the solution conductivity at the reference temperature and recalculate after inputting correctly.

Err.3 standard solution calibration deviation>20% (standard solution concentration error or electrode failure). Confirm the standard solution concentration and recalibrate; If there are repeated errors, replace the electrode.

Err.5 conductivity exceeds the limit (the selected detector range does not match). Select a new detector based on the solution conductivity (low range → SC210G-A, medium range → SC210G-B, high range → SC211G-C).

Err.7/8 temperature exceeds the limit (solution temperature is too high/too low) or temperature sensor malfunction. Check the solution temperature and wait for it to recover to the allowable range; If the temperature is normal, check the sensor wiring or replace the sensor.

Err.10 EEPROM malfunction (abnormal internal storage of transmitter), power outage and restart; If it is ineffective, contact after-sales maintenance.

Err.17 output range setting error (4mA corresponds to conductivity ≥ 60% × 20mA value) Reset the range to ensure that 4mA value<60% × 20mA value.

Spare parts and compliance

1. Key spare parts list

Component spare parts model/specification usage

Replace the faulty electrode components of SC210G electrodes K9208EA (SC210G-A) and K9208JA (SC210G-B) to ensure electrode constant matching.

SC211G electrode K9208BD (electrode constant 10 cm ⁻¹) high range detector dedicated electrode replacement.

Seal O-ring K9050AT to prevent detector interface leakage, and replace regularly in high temperature scenarios.

Replace the scratched or contaminated transparent window of transmitter window K9311JN to ensure clear display.

Install brackets K9149SA (pipeline), K9149SB (wall), K9311KA (panel) for transmitter installation and fixation, suitable for different installation scenarios.

2. Compliance Statement

Explosion proof certification: SC200S intrinsic safety type complies with IECEx and ATEX standards and needs to be used in conjunction with designated safety barriers (BARD400);

Grounding requirements: Non explosion proof systems must comply with JIS Class 1 grounding, while explosion proof systems must be separately equipped with intrinsic safety circuit grounding (resistance ≤ 10 Ω);

Cable specifications: Explosion proof system cable inductance ≤ 2.2 mH, capacitance ≤ 35 nF. It is recommended to use CEV-S cable (up to 700m) or CVV-S cable (up to 350m).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands