YOKOGAWA SC4AJ Conductivity Sensor Manual

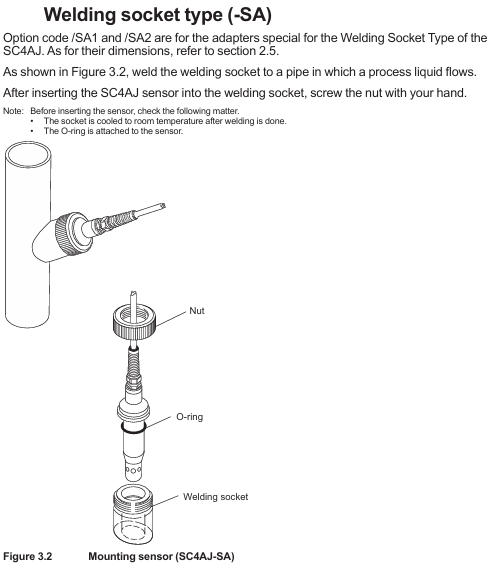

Welding socket type (- SA): First weld the welding socket to the process pipeline (cool to room temperature), insert the sensor into the socket after installing the O-ring, and fix it by hand tightening the nut

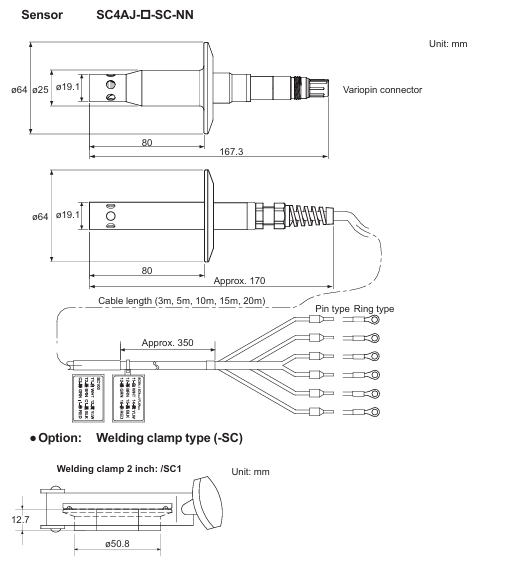

Welding clamp type (- SB/- SC): First weld the flange to the pipeline, insert the sensor into the flange after installing the sealing ring, and fix it with a special fixture

2. Wiring requirements

Wiring logic: Connect according to the cable end identification and the terminal number of the analyzer/converter, for example, connect the temperature sensor wire (brown/black/red) to the corresponding temperature terminal, and the electrode wire (green/yellow) to the corresponding electrode terminal; Variopin terminal (- VS) needs to be connected to SA11 adapter

Cable specifications: Cable length 3-20m (selected according to the order), avoid contact with high-temperature components, and ensure that the insulation resistance meets the requirements after wiring (such as 1000-1137 Ω between terminals 11-12 and>100 M Ω between terminals 11-13)

Operation and maintenance process

1. Preparation and calibration before operation

Pre operation inspection: Confirm that the cable connection is correct, the solution is leak free, the temperature/pressure is within the range, and the solution level reaches the outlet height

Battery constant setting: The factory calibrated battery constant on the cable label needs to be input into the matching analyzer/converter (refer to the corresponding equipment manual for operation steps)

Calibration requirements: Use a standard solution with known conductivity for calibration (the conductivity of the standard solution should be close to that of the test liquid). Before calibration, the sensor should be equilibrated with the temperature of the solution, and the temperature should be measured using a calibration thermometer

2. Core maintenance operations

(1) Sensor cleaning

Choose the cleaning method based on the type of pollutant, and prohibit mixing hydrochloric acid with chlorine containing solvents (to avoid producing toxic chlorine gas):

Scale and hydroxides: Clean with 5-10% hydrochloric acid solution

Organic dirt (oil, grease): Wipe with ethanol or acetone

Algae/bacteria: Clean with chlorine containing solution (household bleach)

Conventional pollution: cleaning with hot water and household detergent

After cleaning, visually inspect the sensor for any damage or deformation

(2) Abnormal judgment

After the sensor dries, measure the resistance between the terminals with a digital multimeter. If it exceeds the following range, it needs to be replaced:

Terminal combination (non VS) Variopin terminal combination (- VS) standard resistance at room temperature

11-12 E-F 1000-1137 Ω

11-13, 13-15, 12-15 E-C, C-A, F-A>100 M Ω

13-14, 15-16 C-D, A-B < 10 Ω

3. Spare parts information

Core spare parts need to be matched according to the installation method, and common spare parts are as follows:

Type description corresponding to spare part number

K9670MA SA (non VS) O-ring

K9670VY SA (- VS) O-ring set

K9670MK-SB sealing ring (compatible/SB1//SB2)

K9670MP SC sealing ring (compatible/SC1)

K9670MT/MU-AD 3/4NPT stainless steel/PVDF adapter

K9670ME/MD-SA straight/angle welding socket and installation nut

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands