Schneider Electric ComPacT NSX DC Circuit Breaker Full Solution and Application Guide

The ComPacT NSX DC series covers rated currents from 16 A to 1200 A and offers multiple pole configurations including 1P, 2P, 3P, and 4P to meet the wiring needs of different systems. Among them, the universal circuit breaker is suitable for critical DC distribution scenarios (such as telecommunications and auxiliary services), while the DC PV and DC EP models designed specifically for photovoltaic and maritime applications are optimized for high voltage and high fault current environments, with stronger breaking capacity and insulation performance.

Schneider Electric ComPacT NSX DC Circuit Breaker Full Solution and Application Guide

Product Series Overview and Application Fields

Schneider Electric's ComPacT NSX DC circuit breaker series is a high-performance protection device designed specifically for DC distribution systems, widely used in industrial distribution, photovoltaic power generation systems, and maritime electrical installations. This series of products complies with the IEC 60947-2 (circuit breakers) and IEC 60947-3 (isolating switches) standards, and has excellent electrical performance and mechanical reliability, suitable for harsh environments with voltages up to 1500 Vdc.

The ComPacT NSX DC series covers rated currents from 16 A to 1200 A and offers multiple pole configurations including 1P, 2P, 3P, and 4P to meet the wiring needs of different systems. Among them, the universal circuit breaker is suitable for critical DC distribution scenarios (such as telecommunications and auxiliary services), while the DC PV and DC EP models designed specifically for photovoltaic and maritime applications are optimized for high voltage and high fault current environments, with stronger breaking capacity and insulation performance.

Circuit breaker operation mode and actuator type

This series of circuit breakers supports multiple operation modes, and users can choose the corresponding actuator according to their actual control needs:

Pull handle: Suitable for NSX100-630 DC series, providing intuitive local opening and closing operations. The handle position clearly indicates the status of the circuit breaker (I-closing, O-opening, TRIP tripping).

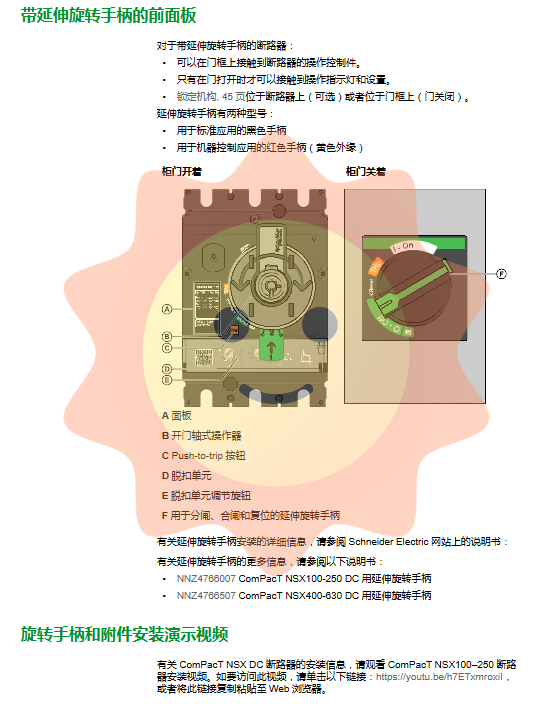

Rotating handle: divided into two types: direct rotation and extended rotation. The extended rotating handle supports operation when the cabinet door is closed, suitable for situations that require door panel installation or cabinet integration, and has door lock interlocking function to enhance operational safety.

Electric operating mechanism: supports remote electrical control and communication network commands, suitable for automated distribution systems. Equipped with manual/automatic mode selection switch, closing spring energy storage indicator and status indicator light, it can achieve flexible switching between local and remote operation.

All operating mechanisms have locking and lead sealing functions to prevent misoperation and unauthorized operation, in compliance with electrical safety regulations.

Install accessories and electrical auxiliary equipment

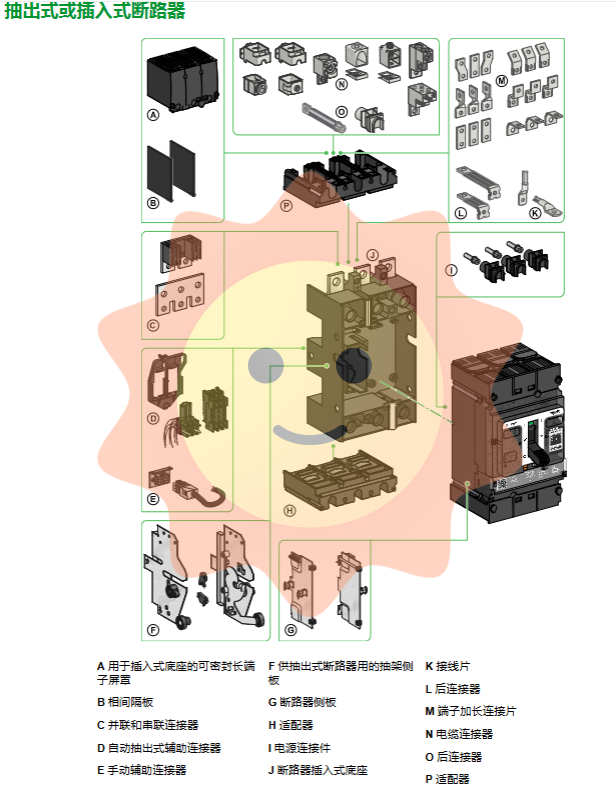

To adapt to different installation scenarios, ComPacT NSX DC offers multiple installation modes:

Fixed installation: suitable for standard distribution cabinet installation, with simple structure and economical cost.

Plug in installation: supports quick replacement of circuit breakers without the need to disassemble power wiring, comes with a plug-in base and safety interlock mechanism to improve maintenance efficiency.

Pull out installation: It has three positions for connection, withdrawal, and removal, which is convenient for testing and maintenance. It is equipped with a pull-out bracket side panel and position contacts, and supports remote status monitoring.

Electrical auxiliary equipment includes status indication, remote control, and communication interfaces, including:

Indicating contacts (OF, SD, SDE): provide signal outputs such as circuit breaker status and trip type.

Wireless indicator auxiliary device: sends the status of the circuit breaker to the gateway or Panel Server through RF communication, supporting local LED status indication and remote monitoring.

Release coils (MN, MX): support undervoltage and shunt release, used for emergency stop or remote release control.

BSCM Modbus SL/ULP module: integrates circuit breakers with Modbus or ULP communication networks, supports status reading, remote control, and event recording.

Configuration and protection characteristics of trip unit

The ComPacT NSX DC circuit breaker adopts a thermal magnetic trip unit, providing dual protection for overload and short circuit:

TM-D series: suitable for general DC applications, some models have adjustable thermal protection and fixed magnetic protection.

TM-DC series: For photovoltaic and high current applications, it supports multi-level regulation of thermal protection and magnetic protection.

TM-DC EP series: designed specifically for 1500 Vdc high voltage environments, with high insulation strength and breaking capacity.

There is an adjustment knob in front of the trip unit, and users can set the overload current (Ir) and short-circuit current (Ii) thresholds according to the load characteristics to ensure protection selectivity. The transparent protective cover can be sealed with lead to prevent tampering with the settings.

Safety standards and maintenance procedures

5.1 Safety operation requirements

All installation, operation, and maintenance work must be carried out by qualified electrical personnel. Before operation, it is necessary to confirm that the power supply has been isolated and verify the power-off status using appropriate voltage level detection equipment. In high-voltage systems such as photovoltaics, strict adherence to insulation and personal protective equipment (PPE) requirements is required.

5.2 Debugging and Daily Inspection

Before new equipment is put into operation or restarted after long-term disuse, a systematic inspection should be conducted, including:

Insulation and dielectric strength testing

Connection torque verification

Mechanical operation and protection function testing

Communication system pairing and verification

5.3 Regular maintenance recommendations

To ensure the long-term reliable operation of circuit breakers, it is recommended to implement a graded maintenance plan:

Basic user maintenance: Conduct annual visual inspection, mechanical operation testing, and accessory status assessment.

User standard maintenance: Conduct protection characteristic verification, connection status inspection, and insulation resistance measurement every 2-3 years.

Manufacturer maintenance: Conduct comprehensive diagnosis, component replacement, and system calibration every 5 years or after a malfunction.

Circuit breakers in photovoltaic applications need to strengthen environmental adaptability checks, including monitoring of sealing, temperature rise, and insulation status.

Fault diagnosis and trip response

After the circuit breaker trips, the reason for the trip should be determined through indicator contacts or wireless devices:

SD indication: may be manual trip, test trip, or coil action.

SDE indication: Indicates electrical fault tripping, downstream equipment malfunction needs to be investigated.

Before restoring power supply, it is necessary to eliminate the cause of the fault and conduct necessary equipment inspections and tests. After short-circuit tripping, the arc residue should be cleaned, the connecting parts should be inspected, and a no-load operation test should be conducted.

Communication integration and intelligent functions

Through the BSCM Modbus SL/ULP module, circuit breakers can be connected to industrial communication networks to achieve:

Remote status monitoring and event recording

Network Control of Electric Mechanisms

Remote firmware update and diagnosis

Integrated with EcoStruxure Power Commission software, supporting project configuration, test report generation, and equipment management

The system supports Modbus SL, ULP, and hybrid communication modes, adapting to different voltage levels and network architecture requirements.

Environmental adaptability design and derating instructions

The ComPacT NSX DC series can operate stably in ambient temperatures ranging from -25 ° C to+70 ° C, and has excellent resistance to vibration, electromagnetic interference, and pollution. In high-altitude areas (>2000 m), voltage and current parameters need to be adjusted according to the derating table to ensure safe operation of the equipment.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands