SCHNEIDER TeSys D Green series AC/DC universal contactor

SCHNEIDER TeSys D Green series AC/DC universal contactor

Introduction: A New Benchmark for Green Energy Efficiency and Intelligent Control

Schneider Electric has always played the role of an innovation leader in the global wave of industrial automation and energy efficiency management. The TeSys D Green series AC/DC universal contactors launched by it not only inherit the excellent reliability and modularity genes of the TeSys family, but also achieve significant breakthroughs in energy efficiency, control accuracy, and compatibility. As a way to obtain Green Premium ™ The eco labeled products in this series strictly comply with environmental regulations such as RoHS and REACH, and provide a complete product environmental profile (PEP) and end-of-life guidance (EoLI), reflecting Schneider Electric's firm commitment to sustainable development.

The core innovation of the TeSys D Green series lies in its AC/DC universal control coil, especially the innovative BBE low-energy coil, which enables the contactor to operate stably with extremely low control power (only 0.5W at 24V DC) and can be directly driven by the digital output module of the PLC, simplifying the system architecture and reducing long-term energy consumption. This article will delve into the technical characteristics, selection methods, accessory systems, and their applications in motor control and starter solutions of this series.

Core advantages and technological innovation

2.1 Five core advantages

Ultra low control energy consumption: The BBE coil maintains a power consumption of only 0.5W under DC 24V, which is significantly reduced compared to traditional coils, helping to improve the overall energy efficiency level of the equipment and reduce control cabinet heating.

Direct PLC control: Thanks to its low driving current (minimum 0.1A), TeSys D Green contactors (especially 40A and above models) can be directly driven by the 24V DC static output (such as 500mA) of commonly used PLCs, without the need for intermediate relays, simplifying wiring, saving space and costs.

High consistency of action: The coil is equipped with continuous current monitoring and control logic, ensuring a fixed opening and closing time that is not affected by voltage fluctuations in the power grid, achieving reliable and highly repetitive actions.

Anti vibration and anti contact vibration: The same current control technology effectively suppresses contact vibration caused by mechanical shock or vibration, protects contacts, and extends electrical life.

Perfect compatibility and inventory optimization: Maintain the exact same external dimensions and terminal types as the traditional TeSys D series, and can be directly replaced as spare parts, greatly reducing maintenance complexity and spare parts inventory pressure for users. Each current level only requires 4 models to cover all control voltages from 24V to 500V (AC/DC), greatly simplifying selection and material management.

2.2 Revolutionary coil technology: BBE and BNE

TeSys D Green offers two main types of universal coils:

BBE coil: specially designed for low energy consumption, with a wide operating voltage range (0.8-1.2 Uc), especially suitable for scenarios directly controlled by PLC or DC power supply.

BNE/EHE/KUE coils: suitable for more traditional control power supplies, with a working voltage range of 0.85-1.1 Uc.

This design allows the same contactor to flexibly adapt to AC or DC control power, providing users with unprecedented configuration flexibility.

Product Series and Selection Guide

3.1 Product Line Coverage

The TeSys D Green series covers rated operating currents (Ie, AC-3400V) from 9A to 80A, corresponding to motor powers ranging from 0.06kW to 37kW. The product is divided into two main connection types:

LC1D09~D38: Using screw clamped terminal connections, the structure is compact and suitable for standard applications.

LC1D40A~D80A: EverLink is used for the main power circuit ® BTR screw terminal (requires dedicated insulated hex wrench), control circuit is screw terminal. This EverLink connection technology provides higher wiring reliability, vibration resistance, and creep resistance, especially suitable for high vibration environments or maintenance free requirements.

3.2 Key selection parameters

Determine the load type and current:

Motor load (AC-3): Select the contactor corresponding to the current level based on the rated power and voltage of the motor (such as 400V).

Resistive load (AC-1): The contactor has a higher rated current under the AC-1 category and can be used for loads such as heaters and lighting.

Select control voltage and coil code: Based on the power supply provided by the control system (AC or DC, 24V-500V), choose the appropriate coil code (BBE, BNE, etc.).

Confirm if attachments are needed, such as auxiliary contacts, delay modules, mechanical locks, etc.

Reference and compatibility with PLC: Schneider Electric provides a detailed compatibility selection table for output modules of M221, M241, M340, M580 and other series PLCs (see page 14 of the original document) to ensure the reliability of direct drive.

Rich modular accessory system

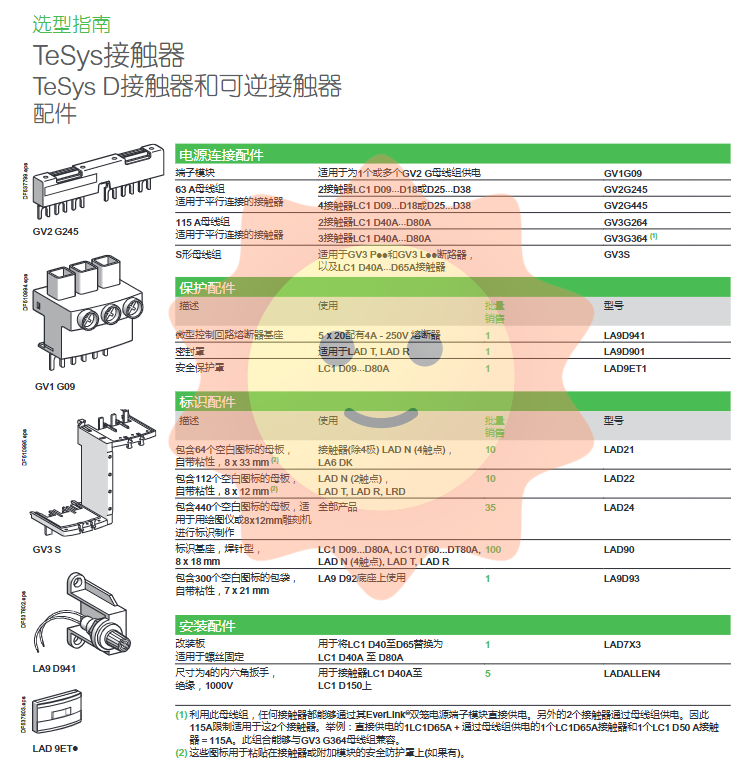

The modular design of TeSys D Green is an extension of its powerful features, and users can flexibly expand its functions by adding side or top mounted accessories:

Auxiliary contact module:

Instantaneous auxiliary contacts (LAD N series): Provides additional NO/NC contacts for status feedback, interlocking, or indication.

Delay auxiliary contact (LAD T/R/S series): Provides power on delay or power-off delay function, with a delay range from 0.1 seconds to 180 seconds, and can be used for timing control such as star delta start.

Mechanical and Electrical Interlocking Module (LAD 6K10+): Used for assembling reversible contactors (forward and reverse control), providing mechanical interlocking to prevent simultaneous power on and off, ensuring safety.

Electronic functional module:

Solid State Relay Interface Module (LA4DWB): Provides isolated solid-state output interfaces.

Timer module (LA4DTU): Integrated delay function.

These modules are installed on LC1D40A~D80A contactors through LA4BB3 wiring adapters.

Connect and protect attachments:

Comb shaped busbar (GV2-G, GV3-G series): used for parallel power supply between multiple contactors or circuit breakers, simplifying cabinet wiring.

EverLink terminal module: convenient for wiring.

Protective Cover (LA9DET): Increases the level of safety protection.

Identification kit: facilitates device identification and management.

Integrated motor starter solution

The TeSys D Green contactor is the core component for building compact and efficient motor starters. Schneider Electric provides mature pre configured solutions:

Direct Starter (DOL):

Cooperate with GV2/GV3 motor circuit breakers to form an integrated starter with short-circuit and overload protection. The document provides a detailed selection comparison table (pages 19-21), clearly listing the circuit breaker models (GV2ME, GV3P, GV3L, NSX molded case circuit breakers) and contactor models (LC1D, LC1F) corresponding to motors ranging from 0.06kW to 250kW, and ensuring compliance with the "Type 1 coordination" requirements of IEC 60947-4-1 standard to ensure the safety of the system under short-circuit faults.

In conjunction with the TeSys GV adapter board system, the LAD311 adapter board allows for quick and neat installation of "circuit breaker+contactor" or "fuse+contactor" modules on DIN rails.

Reversible starter and star delta starter:

By using tool kits such as LAD9R1 and LAD9R3, two standard contactors can be easily assembled into reversible contactors with mechanical interlocks (LC2 series).

Provide dedicated star delta starter assembly kit (LAD9SD3, etc.), including delay contact module and all necessary connection bars.

Prefabricated Wiring System (TeSys SoLink):

This is an innovative solution for the future. By connecting the LADC module, the control and monitoring circuits of circuit breakers, contactors, and auxiliary contacts are integrated into the standard RJ45 interface. They are quickly connected to the PLC's I/O module through prefabricated cables, greatly reducing the workload of control circuit wiring in the cabinet and improving reliability and maintainability.

Core technical parameters and design points

Electrical and mechanical lifespan:

The mechanical lifespan can reach millions of operations.

The electrical lifespan (AC-3) can reach millions of times under rated conditions, and specific data needs to refer to the official data sheet.

Coil characteristics:

The suction time is about 50-60ms, and the breaking time is about 25ms, with precise movements.

Capable of operating within a wide voltage range and reliably releasing at voltages as low as 0.1Uc.

Installation and wiring:

Supports 35mm standard DIN rail (such as AM1DP200) installation, as well as panel screw installation.

Provide detailed recommendations for wire cross-sectional area (screw terminals support 1-35mm ², EverLink terminals support 1-25/35mm ²), and specify the correct tightening torque.

Environmental adaptability:

Working temperature range: -5 ° C to+60 ° C.

Storage temperature range: -60 ° C to+80 ° C.

The highest working altitude is 3000 meters without capacity reduction.

Protection level: Front IP20, preventing direct contact of fingers with live parts.

Application Value and Summary

The Schneider Electric TeSys D Green AC/DC universal contactor series is not just a component upgrade, it represents the trend of industrial control towards higher energy efficiency, higher integration, and more intelligent convenience. Its value is reflected in:

Reduce costs and increase efficiency for enterprises: Low energy coils save electricity costs, direct PLC drive saves components and cabinet space, modular design reduces inventory types.

Improving system reliability: Constant operating characteristics, excellent anti vibration design, extensive international certifications (UL, CSA, CCC, etc.), and a perfect "coordination" solution with upstream circuit breakers ensure long-term stable operation of the system.

Accelerate engineering and maintenance: Clear selection table, rich pre configured solutions, and SoLink prefabricated wiring significantly shorten design, installation, and maintenance time.

Practice sustainable development: comply with strict environmental standards and help users achieve green manufacturing goals.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands