SCHNEIDER XB2-B Ø 22mm series buttons, selection switches, and indicator lights

The essence of modular design lies in the separation of the base and module. The base of the XB2B series is not only a carrier for connecting electrical ports, but also a basic platform for functional expansion.

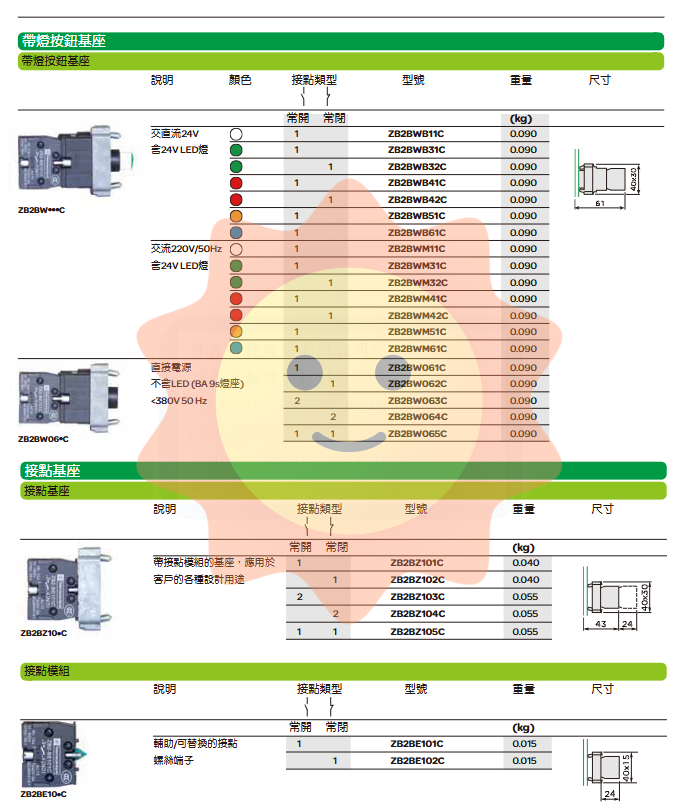

1. Contact point base

This is the most basic base model (ZB2BZ101C, ZB2BZ102C, etc.), designed specifically for installing various metal or plastic modules. It provides installation space for the main contacts (1NO+1NC). If no auxiliary contacts are needed, this is the most economical option.

2. Base with indicator light

Combining the indicator light with the operating mechanism can effectively save panel space.

ZB2BWB series: Integrated 24V DC indicator light.

ZB2BWM series: Integrated 220V AC indicator light.

ZB2BW06 series: direct power type (excluding LED, requiring BA9s lamp holder), suitable for specific voltages such as 380V AC.

This type of base usually comes with one set of main contacts (1NO+1NC) and reserves a position for indicator lights at the top.

3. Customer customization and auxiliary touchpoints

Auxiliary contact module: A base can accommodate up to 6 sets of auxiliary contacts (ZB2BE101C/102C). Auxiliary contacts are used in control logic for signal feedback (such as "device closed", "fault confirmed"), while main contacts are used to control high current loads.

Customer customized base (ZB2BZ103C/104C): Schneider provides customized services, allowing customers to pre install specific modules in the base, achieve functional integration, and reduce external wiring and fault points.

Wiring and Installation: Engineering Considerations

The XB2B series adopts the standard screw terminal connection method. This connection method is widely popular in industrial environments due to its high connection reliability and strong anti vibration ability.

Wiring ability:

Single wire: can be connected up to a maximum of 2.5mm ².

Wire with terminal piece (end): can connect up to 2 x 1.5mm ².

Minimum wire diameter: 1 x 0.5mm ².

This broad wiring range can meet the connection requirements from small signal lines to relatively thick control lines.

Terminal material: Silver cadmium oxide contacts are usually used, with good conductivity and strong resistance to welding.

Practical Selection Guide: How to Understand Models

In order to make precise selections, engineers need to master the naming conventions of the XB2B series models. A complete XB2B model typically consists of the following parts (taking the illuminated button as an example):

XB2 B [W] [M] [3] [1] C

XB2: Refers to the Metal series.

B: Indicating a 22mm aperture.

W: Indicate the type of function, for example, W=with indicator light, B=flat head button, L=convex head button, C=mushroom head, D=selection switch.

M: Representing color codes, such as W=white, R=red, G=green.

Number 1: Indicates the color of the indicator light (e.g. 1=white, 3=green) or the type of contact (e.g. 1=1NO+1NC).

Number 2: represents the number of contacts, for example 3=2NO+2NC (to be defined in conjunction with the base).

Selection case:

Requirement: A start button with a green indicator light, 220V AC voltage, panel aperture of 22mm, and 1NO+1NC contacts are needed.

Selection steps:

Determine the base: Select the base with 220V AC green light, refer to the catalog and find ZB2BWM32C (WB=base with light, M=with LED, 3=green, 2=220V AC, C=base assembly with light).

Confirm module: Select the flat button, green, and look up the directory to find XB2BVA32C (VA=flat button, A=spring reset, 3=green, 2=1NO+1NC).

Combination: Insert module XB2BVA32C into base ZB2BWM32C.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands