SCHNEIDER XB2-B Ø 22mm series buttons, selection switches, and indicator lights

SCHNEIDER XB2-B Ø 22mm series buttons, selection switches, and indicator lights

Introduction: Precision Touch in Industrial Control

In modern industrial automation and control system design, every subtle component is related to the stability and operational efficiency of the entire system. As an important component of the Human Machine Interface (HMI), buttons and indicator lights play a crucial role in signal input, device control, and status feedback. Schneider Electric, as a global expert in digital transformation in energy management and automation, has launched the XB2B series of 22mm metal buttons and indicator lights, which are classic products designed to meet the demands for high performance, high reliability, and strong adaptability in industrial environments.

The XB2B series not only covers simple flat head buttons to complex emergency stop switches, selection switches, and various indicator lights, but also provides engineers with great configuration flexibility through its modular design concept. This article will delve into the technical specifications, structural characteristics, electrical parameters, and selection guidelines of this series, aiming to provide detailed technical references for the design, selection, and maintenance of industrial control systems.

Core design concept: 22mm standard and modularization

Standardization of installation aperture is crucial for reducing costs and improving installation efficiency in industrial control panel design. The XB2B series adopts a universal 22mm mounting aperture, which not only conforms to ergonomics and facilitates precise pressing by operators, but also is highly compatible with international mainstream control cabinet design specifications.

The most notable design feature of this series is its modular structure. Unlike traditional integral control components, the XB2B series adopts a "split" supply mode, which separates the contact base (ZB2B series) from the operation module (XB2B series). This design brings multiple advantages:

Inventory management optimization: Users can store universal bases and modules with different functions according to project requirements, greatly reducing stocking pressure.

Easy maintenance and upgrade: When the device function changes or the module is damaged, there is no need to disassemble the wiring, only the upper module needs to be replaced, achieving fast maintenance.

Flexible configuration: The same base can accommodate multiple types of buttons or indicator lights to meet the needs of temporary changes on site.

Deep analysis of technical specifications: reliable guarantee in harsh environments

Industrial sites are often accompanied by high temperatures, high humidity, vibrations, and electromagnetic interference. The XB2B series strictly follows the International Electrotechnical Commission (IEC) standards, especially IEC 60947-5-1 (Control Circuit Electrical Appliances and Switching Components) and GB/T 14048.1-93 national standards, ensuring excellent performance of the product in various harsh environments.

1. Electrical performance and insulation characteristics

Rated working characteristics:

AC-15 (AC): At a rated voltage of 240V, the rated current can reach 6A. The AC-15 category indicates that this product is suitable for controlling high inductive loads, such as contactor coils.

DC-13 (DC): At a rated voltage of 250V, the rated current is 0.27A. The DC-13 category indicates that this product is suitable for controlling mixed loads of resistance and inductance, such as DC electromagnets.

Load factor: 0.5, which is an important parameter for measuring the arc extinguishing ability of different contact materials in opening and closing inductor circuits.

Insulation and voltage resistance:

Rated insulation voltage: 600V, which means that the electrical clearance and creepage distance inside the product can support a working voltage of up to 600V, preventing breakdown.

Rated impulse withstand voltage (Uimp): 6kV, proving that the product has the ability to resist lightning strikes or power grid surges.

Anti interference capability:

Electronic protection: Level I, compliant with IEC 536 and NFC 20-030 standards, ensuring that no misoperation occurs in strong electromagnetic environments.

2. Mechanical performance and durability

Mechanical lifespan:

Normal buttons and selection switches: 3000000 (3 million) operations. This astonishing lifespan indicator means that the product can still maintain long-term mechanical stability in frequent operating situations, greatly reducing the frequency of replacement.

Emergency stop button: 300000 operations. Due to the fact that emergency stop buttons are usually equipped with stronger reset springs to ensure the reliability of forced contact disconnection, their mechanical life is relatively short, but this fully meets the high durability requirements of safety standards for emergency stop equipment.

Vibration and impact resistance:

Vibration resistance: Ordinary buttons and indicator lights comply with 8g (10-2000Hz), mushroom head buttons comply with 15g (40-500Hz), and comply with IEC 68-2-6 standard.

Impact resistance: The ordinary button weighs 70g, the mushroom head button weighs 15g, the selector switch weighs 200g, and complies with the IEC 68-2-27 standard.

These indicators ensure that the product can still be securely connected in high vibration environments such as large machinery and stamping equipment, without loosening or misoperation.

3. Environmental adaptability and protection level

Ambient temperature

Working temperature range: -25 ℃ to+70 ℃.

Storage temperature range: -40 ℃ to+70 ℃.

This wide temperature range enables the XB2B series to adapt to environments ranging from cold outdoor environments to high-temperature workshop interiors.

Protection level (IP):

IP65: Flat head and convex head buttons (with or without indicator lights), as well as mushroom head buttons, can achieve IP65 rating after installation, which means they are completely dust-proof and can withstand low-pressure water spray.

IP66: With a covered button, it can reach IP66 rating and withstand the impact of strong waves or high-pressure water flow.

Protective treatment: The standard version adopts "TC" (heat-resistant) and "TH" (flame-retardant) protective treatment, and the material meets UL 94 V-0 level, with excellent flame-retardant properties, which can effectively prevent the spread of fire in the event of a fire.

Product Series Explanation: Comprehensive Control and Feedback

The XB2B series is mainly divided into three categories: buttons and selection switches, emergency stop buttons, and indicator lights.

1. Buttons and selection switches

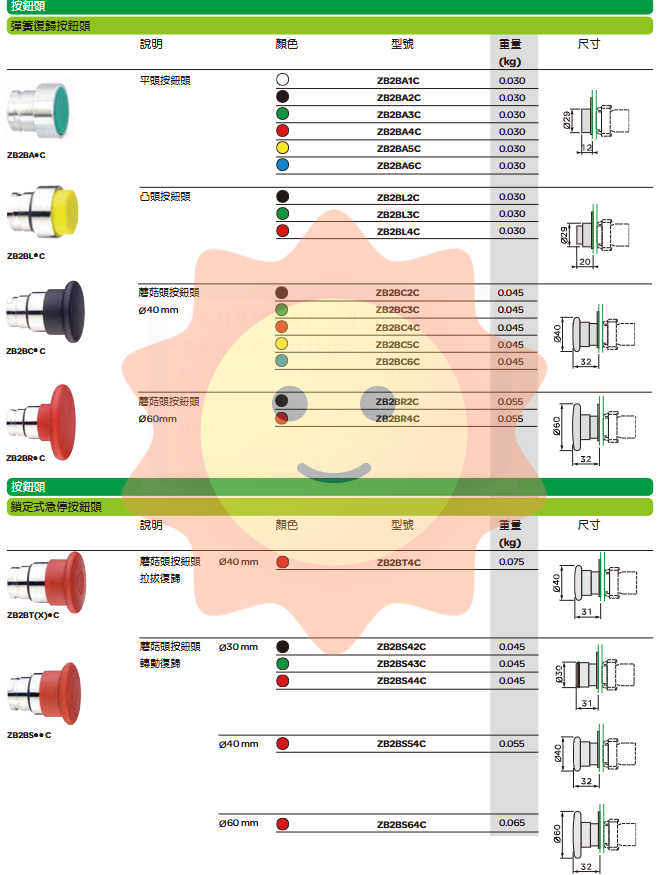

Normal button:

Flat head button (ZB2BA series): ergonomically designed with a flat front, suitable for frequent daily operations.

Convex head button (ZB2BL series): The head is raised to prevent accidental contact, and is commonly used in situations where it is necessary to distinguish the priority of operations.

Mushroom head button (ZB2BC series): With a larger head diameter (Ø 40mm or Ø 60mm), it is easier to identify and press, and is usually used for important start stop control.

These buttons can be optionally equipped with spring reset (rebound upon release) or self-locking function (hold after pressing, need to be released again).

Select switch:

Standard Handle Selection Switch (ZB2BD Series): Switch gears by rotating the handle, providing 2 or 3 options with clear positioning feel.

Key selection switch (ZB2BG series): combines permission management and mode selection functions. According to different operating methods, it can be divided into:

Spring reset: After the key is removed, the handle is reset to zero position.

Key extraction: The key can only be extracted or inserted in a specific position (such as the OFF position).

Key detachable: The key can be removed or inserted from any position.

This type of switch plays a critical role in preventing unauthorized operations and ensuring process safety.

2. Emergency stop button: safety first forced disconnection

In industrial safety design, emergency stop is an indispensable part. The XB2B series provides emergency stop solutions that comply with the IEC 60947-5-1 Part 3 standard.

Characteristics:

Forced disconnection: The mechanical structure design of the emergency stop button ensures that when the emergency stop button is pressed, the normally closed (NC) contacts can be reliably forced to disconnect. Even if the contacts are fused, they can be separated by the movement of the mechanical linkage, ensuring absolute circuit disconnection.

Reset method:

Pulling and resetting (ZB2BT series): The operator must pull up the mushroom head after confirming that the fault has been eliminated before resetting, effectively preventing the equipment from automatically restarting without removing the danger.

Rotation reset (ZB2BS series): The mushroom head needs to be rotated to the reset mark. This design is suitable for scenarios where space is limited or specific action confirmation is required.

Color and logo: Adopting a standard yellow base and red mushroom head, meeting the visual warning requirements of international safety standards. The red lens on the head also bears an emergency stop symbol.

3. Indicator light: Clear status feedback

The XB2B series indicator lights adopt universal LED technology, which has advantages such as low power consumption, long lifespan, and good shock resistance compared to traditional light bulbs.

Voltage level:

XB2BVB (AC/DC 24V): Strong compatibility, widely used in control cabinets.

XB2BVQ (AC 380V)/XB2BVM (AC 220V): Suitable for direct connection to industrial control voltage without the need for additional transformers.

XB2BVMD (DC 220V): meets the requirements of specific DC circuits.

Power and color:

The power consumption is only 0.5W at 24V and 4.5W at 220V, and the low-power design helps save energy.

Provide multiple color options including red, green, yellow, blue, white, orange, etc., in accordance with the definition of colors in IEC 60947-5-1 (red=stop/fault, green=operation, yellow=warning/caution, etc.).

Lamp lifespan: can exceed 50000 hours at rated voltage.

Modular system: flexible combination of base and contact points

The essence of modular design lies in the separation of the base and module. The base of the XB2B series is not only a carrier for connecting electrical ports, but also a basic platform for functional expansion.

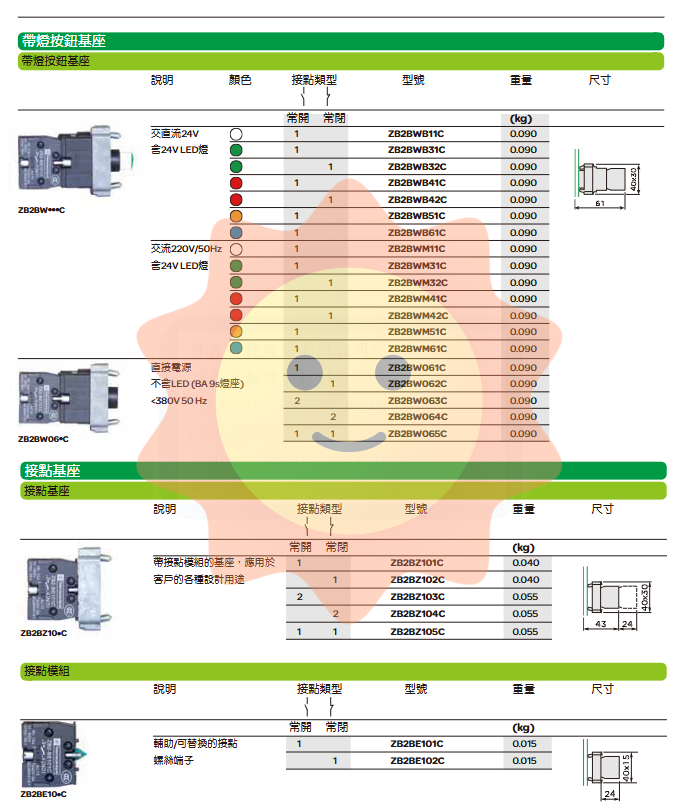

1. Contact point base

This is the most basic base model (ZB2BZ101C, ZB2BZ102C, etc.), designed specifically for installing various metal or plastic modules. It provides installation space for the main contacts (1NO+1NC). If no auxiliary contacts are needed, this is the most economical option.

2. Base with indicator light

Combining the indicator light with the operating mechanism can effectively save panel space.

ZB2BWB series: Integrated 24V DC indicator light.

ZB2BWM series: Integrated 220V AC indicator light.

ZB2BW06 series: direct power type (excluding LED, requiring BA9s lamp holder), suitable for specific voltages such as 380V AC.

This type of base usually comes with one set of main contacts (1NO+1NC) and reserves a position for indicator lights at the top.

3. Customer customization and auxiliary touchpoints

Auxiliary contact module: A base can accommodate up to 6 sets of auxiliary contacts (ZB2BE101C/102C). Auxiliary contacts are used in control logic for signal feedback (such as "device closed", "fault confirmed"), while main contacts are used to control high current loads.

Customer customized base (ZB2BZ103C/104C): Schneider provides customized services, allowing customers to pre install specific modules in the base, achieve functional integration, and reduce external wiring and fault points.

Wiring and Installation: Engineering Considerations

The XB2B series adopts the standard screw terminal connection method. This connection method is widely popular in industrial environments due to its high connection reliability and strong anti vibration ability.

Wiring ability:

Single wire: can be connected up to a maximum of 2.5mm ².

Wire with terminal piece (end): can connect up to 2 x 1.5mm ².

Minimum wire diameter: 1 x 0.5mm ².

This broad wiring range can meet the connection requirements from small signal lines to relatively thick control lines.

Terminal material: Silver cadmium oxide contacts are usually used, with good conductivity and strong resistance to welding.

Practical Selection Guide: How to Understand Models

In order to make precise selections, engineers need to master the naming conventions of the XB2B series models. A complete XB2B model typically consists of the following parts (taking the illuminated button as an example):

XB2 B [W] [M] [3] [1] C

XB2: Refers to the Metal series.

B: Indicating a 22mm aperture.

W: Indicate the type of function, for example, W=with indicator light, B=flat head button, L=convex head button, C=mushroom head, D=selection switch.

M: Representing color codes, such as W=white, R=red, G=green.

Number 1: Indicates the color of the indicator light (e.g. 1=white, 3=green) or the type of contact (e.g. 1=1NO+1NC).

Number 2: represents the number of contacts, for example 3=2NO+2NC (to be defined in conjunction with the base).

Selection case:

Requirement: A start button with a green indicator light, 220V AC voltage, panel aperture of 22mm, and 1NO+1NC contacts are needed.

Selection steps:

Determine the base: Select the base with 220V AC green light, refer to the catalog and find ZB2BWM32C (WB=base with light, M=with LED, 3=green, 2=220V AC, C=base assembly with light).

Confirm module: Select the flat button, green, and look up the directory to find XB2BVA32C (VA=flat button, A=spring reset, 3=green, 2=1NO+1NC).

Combination: Insert module XB2BVA32C into base ZB2BWM32C.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands