SEW MOVIDRIVE ® MD-60A Inverter: Comprehensive Technical Analysis of Industrial Drive Solutions

Start debugging and parameter optimization

Startup debugging is a key step to ensure the matching between the frequency converter and the motor. The manual provides two ways:

Using DBG11A keyboard:

Suitable for VFC mode, supporting motor type recognition, rated data input, and speed loop self-tuning.

The startup menu structure is clear, and the steps include: selecting parameter sets, operating modes, motor models, voltage and frequency, and performing automatic calculations.

For non SEW motors, it is necessary to manually input parameters such as rated current, power, power factor, and speed.

Using MOVITOOLS software (PC connection):

Supports all operating modes (VFC, CFC, SERVO) for more comprehensive functionality.

Parameters can be configured, monitoring status, and parameter sets can be downloaded and uploaded through a graphical interface.

Key parameter settings:

The PI parameters of the speed loop (P200, P201), current limit (P303), and acceleration/deceleration time (P130-P147) need to be adjusted according to the actual load.

The braking function (P730-P735) needs to be set with reasonable release and closing time to avoid mechanical impact.

Encoder monitoring (P504) needs to be activated when closed-loop control is enabled, but be aware of its non safety functional attributes.

Fault diagnosis and maintenance strategy

The equipment has a complete fault protection and information recording mechanism:

Fault classification and response:

Immediately shut down (such as overcurrent, grounding fault)

Quick stop (decelerate according to the stopping slope)

Emergency stop (decelerate according to the emergency stop slope)

Alarm only without stopping (such as TF sensor triggering)

Fault code and handling:

Displayed on the 7-segment digital display (such as "04" indicating brake chopper fault), the DBG11A screen displays detailed information.

Common faults include overload (F84), encoder signal abnormality (F14), communication timeout (F28/F43), etc. The manual provides possible causes and handling suggestions.

Maintenance and repair:

The device has a built-in fault memory (P080-P084) that records the last 5 faults and related operational data.

If the fault cannot be resolved, please contact SEW service and provide the device serial number, service code, fault description, and application environment information.

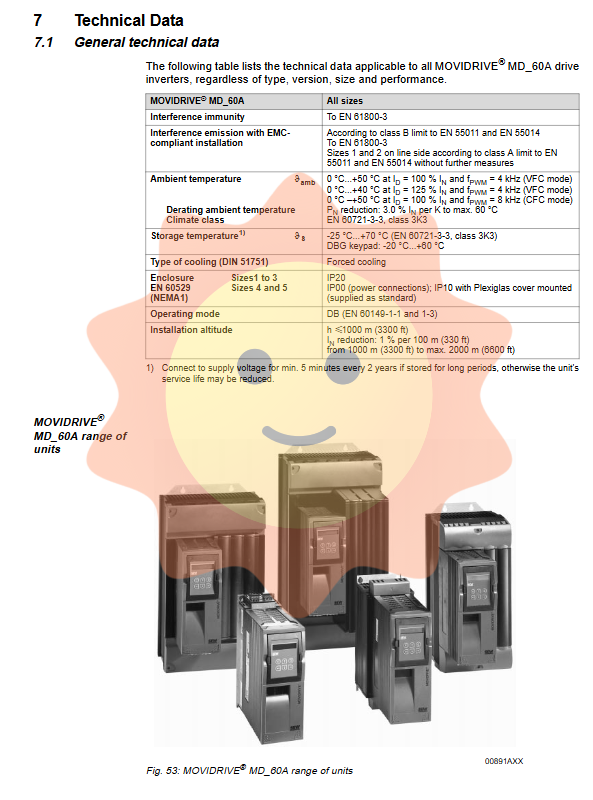

Overview of Technical Data

MOVIDRIVE ® The MD-60A series covers power ranges from 1.5 kW to 90 kW (230V model) and 2.2 kW to 90 kW (400/500V model). Its general technical data includes:

Environmental temperature: 0... 50 ° C (100% load), needs to be reduced to 60 ° C for use.

Protection level: IP20 (size 1-3), IP00/optional IP10 (size 4-5 with protective cover).

Supports adjustable PWM frequency (4/8/12/16 kHz), speed control range ± 5000 rpm, resolution 0.2 rpm.

The electronic terminals support 0.2-2.5 mm ² wires, and the digital input and output comply with PLC compatibility standards (EN 61131).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands