SEW MOVIDRIVE ® MD-60A Inverter: Comprehensive Technical Analysis of Industrial Drive Solutions

SEW MOVIDRIVE ® MD-60A Inverter: Comprehensive Technical Analysis of Industrial Drive Solutions

MOVIDRIVE ® The MD-60A series frequency converter is a high-performance industrial drive launched by SEW-EURODRIVE, designed specifically for AC asynchronous motors and permanent magnet synchronous motors, suitable for precise motion control in industrial and commercial systems. This article is based on the official operation manual, combined with technical details and application practice, to systematically analyze it, covering design principles, installation specifications, startup debugging, parameter configuration, fault diagnosis and maintenance points, aiming to provide engineering and technical personnel with an in-depth and practical technical reference.

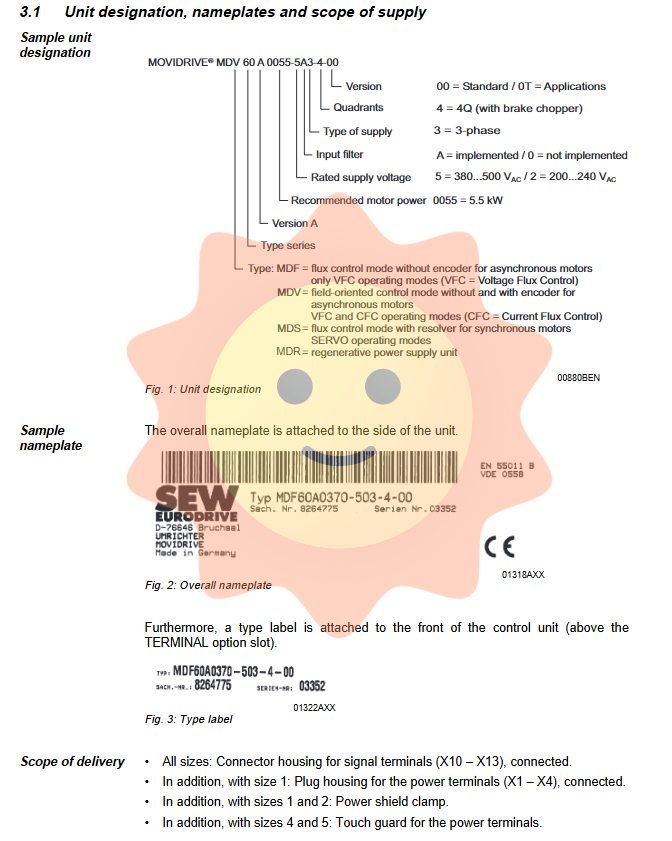

Product Overview and Design Features

MOVIDRIVE ® MD-60A is a modular and scalable frequency converter series, available in five size specifications (size 1 to size 5), suitable for two voltage levels of 230V and 400/500V. Its core design concept lies in high integration and flexible configuration capability, supporting multiple operating modes such as VFC (voltage frequency control), CFC (current frequency control), and SERVO (servo control), and can be expanded through optional boards, such as fieldbus interface, encoder interface, I/O expansion, etc.

In terms of equipment structure, all models are equipped with:

Control unit area, including 7-segment digital display, DBG11A keyboard interface, electronic terminal block (X10-X13), and two option slots (OPTION1/OPTION2).

The power unit area includes power input (X1), motor output (X2), brake resistor connection (X3), and DC bus interface (X4).

Safety and shielding design: Sizes 1 and 2 come standard with power shielding clips, while Sizes 4 and 5 come standard with touch protection covers to enhance installation safety and electromagnetic compatibility.

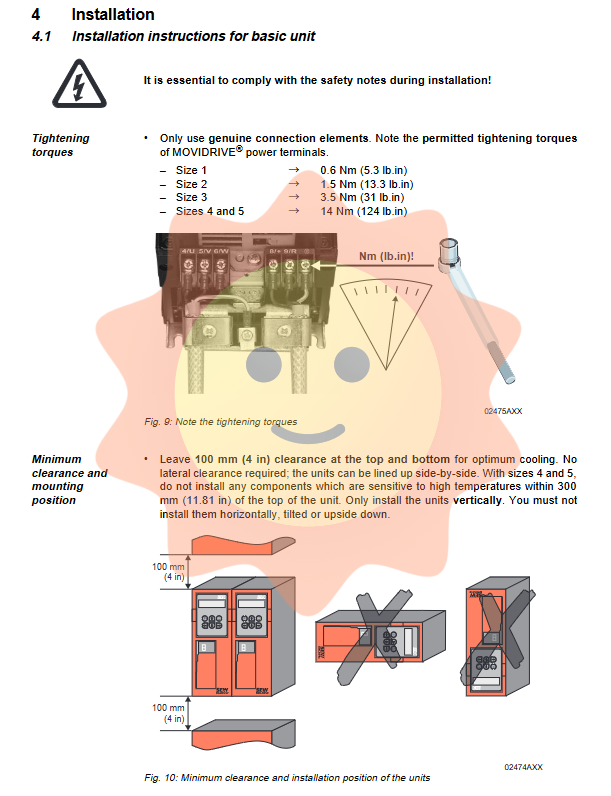

The equipment is named clearly and the nameplate information is complete, making it easy to identify and trace. During installation, it is necessary to strictly follow the requirements of vertical installation and reserved heat dissipation spacing (at least 100mm at the top and bottom), and pay attention to the tightening torque of different sizes (such as 0.6 Nm for size 1 and 14 Nm for sizes 4-5).

Safety and Installation Standards: Ensuring Reliable System Operation

Safety is the top priority of industrial equipment. The manual repeatedly emphasizes:

Security Warning:

The device cannot independently undertake security functions and must rely on the higher-level security monitoring system.

Prohibited from use in explosion-proof areas, environments with harmful chemicals or strong mechanical vibrations.

Before disassembling the protective cover, the power must be disconnected and wait for at least 10 minutes to release the internal energy storage.

Key points of electrical installation:

The power line and signal line must be laid in separate slots, and the shielding layer should be grounded at both ends and achieve large-area contact through metal clips or cable joints.

The PE (protective grounding) connection must comply with the EN 50178 standard. When the cross-sectional area of the power line is less than 10 mm ², a second PE line must be connected in parallel.

Only inductive loads (motors) are allowed to be connected to the output terminal, and capacitive loads are prohibited from being connected.

EMC and filtering design:

To meet the electromagnetic compatibility Class A/B restrictions, input filters (NF series) and output reactors (HD series) need to be selected according to the equipment size.

It is recommended to use shielded cables for motor cables, and the filter should be installed as close to the frequency converter as possible. The length of the connecting cable should not exceed 400mm.

Braking resistor and thermal management:

The connecting wire of the braking resistor needs to use a twisted pair shielded power cable, and the surface of the resistor is high temperature. It should be installed on the top of the electrical cabinet and equipped with a protective cover.

It is necessary to match the braking resistor (such as BW series) with the frequency converter model and set up bimetallic relay protection.

System connection and communication interface

MOVIDRIVE ® MD_60A supports multiple communication methods, making it easy to integrate into automation systems:

System Bus (SBus):

Based on CAN bus (ISO 11898), up to 64 stations can be connected.

A twisted pair shielded cable (such as a CAN bus dedicated cable) is required, and the terminal resistance is set through switch S12.

The bus length is related to the baud rate: the longest is 320m at 125 kbaud, and only 40m at 1000 kbaud.

RS-485 interface:

Support multi-point communication, up to 32 devices, can be used for master-slave control.

Use Belden 3105A twisted pair shielded cable with a maximum length of 200m and built-in dynamic termination resistor.

Option Expansion:

RS-232/RS-485 conversion can be achieved through the USS21A module, making it easy to connect to a PC for debugging.

Optional boards (such as DIO11A digital expansion, DFP11A fieldbus interface, etc.) can be inserted into the OPTION slot, and should be discharged and operated carefully before installation.

Start debugging and parameter optimization

Startup debugging is a key step to ensure the matching between the frequency converter and the motor. The manual provides two ways:

Using DBG11A keyboard:

Suitable for VFC mode, supporting motor type recognition, rated data input, and speed loop self-tuning.

The startup menu structure is clear, and the steps include: selecting parameter sets, operating modes, motor models, voltage and frequency, and performing automatic calculations.

For non SEW motors, it is necessary to manually input parameters such as rated current, power, power factor, and speed.

Using MOVITOOLS software (PC connection):

Supports all operating modes (VFC, CFC, SERVO) for more comprehensive functionality.

Parameters can be configured, monitoring status, and parameter sets can be downloaded and uploaded through a graphical interface.

Key parameter settings:

The PI parameters of the speed loop (P200, P201), current limit (P303), and acceleration/deceleration time (P130-P147) need to be adjusted according to the actual load.

The braking function (P730-P735) needs to be set with reasonable release and closing time to avoid mechanical impact.

Encoder monitoring (P504) needs to be activated when closed-loop control is enabled, but be aware of its non safety functional attributes.

Fault diagnosis and maintenance strategy

The equipment has a complete fault protection and information recording mechanism:

Fault classification and response:

Immediately shut down (such as overcurrent, grounding fault)

Quick stop (decelerate according to the stopping slope)

Emergency stop (decelerate according to the emergency stop slope)

Alarm only without stopping (such as TF sensor triggering)

Fault code and handling:

Displayed on the 7-segment digital display (such as "04" indicating brake chopper fault), the DBG11A screen displays detailed information.

Common faults include overload (F84), encoder signal abnormality (F14), communication timeout (F28/F43), etc. The manual provides possible causes and handling suggestions.

Maintenance and repair:

The device has a built-in fault memory (P080-P084) that records the last 5 faults and related operational data.

If the fault cannot be resolved, please contact SEW service and provide the device serial number, service code, fault description, and application environment information.

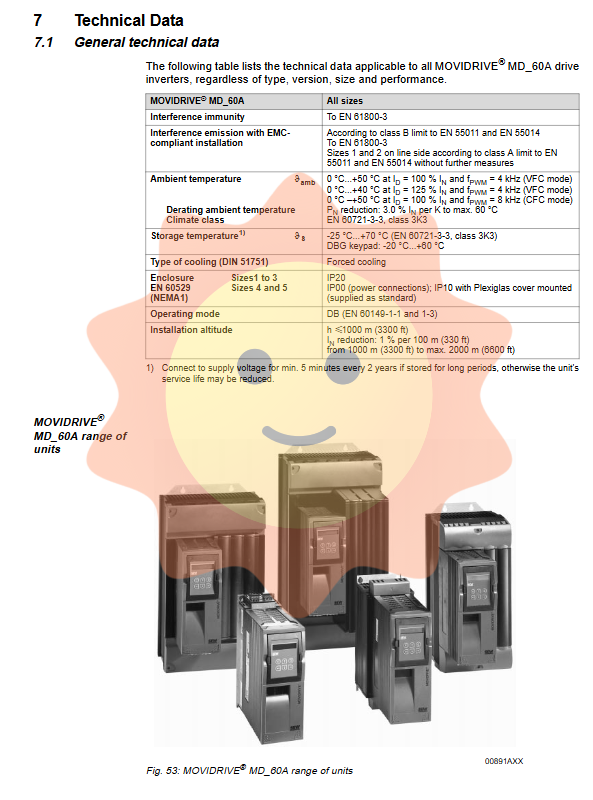

Overview of Technical Data

MOVIDRIVE ® The MD-60A series covers power ranges from 1.5 kW to 90 kW (230V model) and 2.2 kW to 90 kW (400/500V model). Its general technical data includes:

Environmental temperature: 0... 50 ° C (100% load), needs to be reduced to 60 ° C for use.

Protection level: IP20 (size 1-3), IP00/optional IP10 (size 4-5 with protective cover).

Supports adjustable PWM frequency (4/8/12/16 kHz), speed control range ± 5000 rpm, resolution 0.2 rpm.

The electronic terminals support 0.2-2.5 mm ² wires, and the digital input and output comply with PLC compatibility standards (EN 61131).

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands