SEW MOVIDYN ® Complete Guide for Installation, Debugging, and Maintenance of Servo Controllers

SEW MOVIDYN ® Complete Guide for Installation, Debugging, and Maintenance of Servo Controllers

MOVIDYN ® The servo controller is a permanent magnet synchronous servo motor drive device developed by SEW-EURODRIVE for industrial and commercial systems, suitable for automation scenarios that require high-precision motion control. This article is based on the official operating manual (09223711/EN), which systematically outlines the entire process of installation, debugging, operation, and maintenance, providing engineers with a complete and reliable technical guide.

Product Overview and Safety Standards

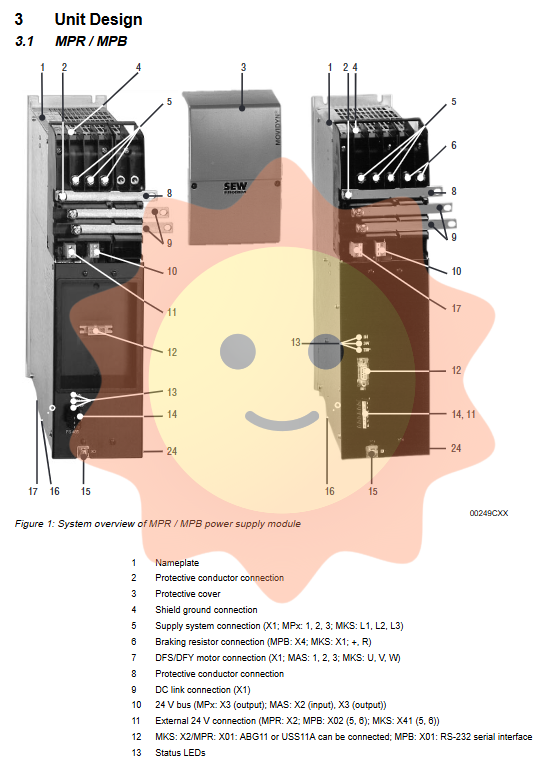

MOVIDYN ® The series includes various modular components: MPR/MPB power module, MAS axis module, and MKS compact servo controller. Its design complies with the Low Voltage Directive 73/23/EWG and the EMC Directive 89/336/EWG, has the CE mark, and is suitable for fixed installation in control cabinets. It is strictly prohibited to use it in non-standard environments such as explosion-proof areas, strong corrosion, and high vibration.

Safety is the primary prerequisite: all installation, commissioning, and maintenance work must be carried out by personnel with electrical professional qualifications, and strictly comply with safety regulations such as EN 60204 and VDE 0100. Before operation, it is necessary to ensure that:

Completely power off the device and wait for at least 10 minutes to release residual voltage;

The motor will not start unexpectedly;

The protective cover plate is installed properly (the protection level is reduced to IP00 after opening the cover);

Braking control must be achieved through the controller output terminal (such as X21.9) and cannot be directly controlled by PLC to avoid system loss of control.

Mechanical installation and heat dissipation design

2.1 Installation Environment and Layout

The controller should be installed in a clean, dry, and well ventilated control cabinet to avoid dust accumulation and condensation. If forced air cooling is used, ventilation filters need to be installed.

2.2 Requirements for radiator installation

At least 100mm of cooling space should be reserved above and below the radiator;

The module must be fully installed on the same heat sink and cannot be connected across two heat sinks;

There is no need to apply thermal paste during installation, and the screw torque should not exceed 3.5 Nm;

In a multi axis system, electrical connections between radiators should be made through wires or braided tapes of ≥ 10mm ² to ensure grounding continuity.

2.3 Module Layout Suggestions

The shaft module should be installed on the right side of the power module for 24 VDC bus connection;

The braking resistor should be installed in a well ventilated area (such as on the top of a cabinet), and attention should be paid to its surface temperature being extremely high at rated power;

The line reactor should be installed close to the corresponding module, but should not occupy cooling space.

Electrical installation and wiring specifications

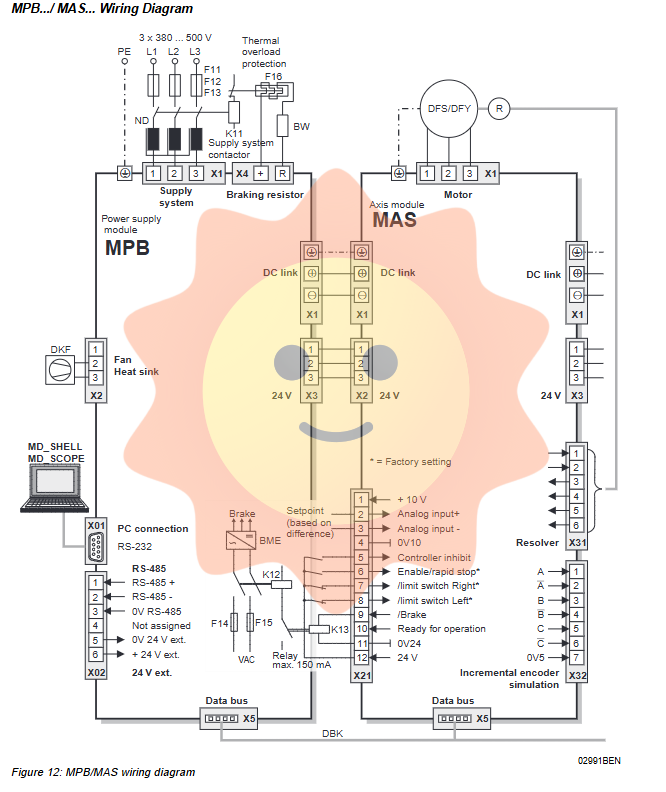

3.1 Connection between power supply and motor

The power input terminals (L1, L2, L3) and motor output terminals (U, V, W) must be labeled and tightened according to IEC 445 standard, with a torque of ≤ 3.5 Nm;

The length of the motor cable should not exceed 100 meters and should be laid away from other lines. Shielded cables should be used if necessary;

Output filters shall not be used between servo controllers and motors.

3.2 Connection between braking resistor and cooling fan

Connect the braking resistor to the X4 (+, R) terminal of the MPB module or the X1 (+, R) terminal of the MKS controller;

Cables should be laid in pairs (such as twisted pair cables), with a cross-sectional design based on the maximum braking current;

The cooling fan (DKF type) is connected by polarity: black connected to X2.2/X6.2, red connected to X2.3/X6.1.

3.3 24 VDC power distribution

The 24 VDC power consumption of each module needs to be accurately calculated:

The maximum output of the MPB51A internal 24V power supply is 240 W, MPR51A is 50 W, and MKS51A is 29 W;

The power consumption of the MAS axis module increases with the rated current (5 W to 15 W);

If the internal power supply is insufficient, an external 24-30 VDC power supply is required; If used only for maintaining communication during power outages, the voltage range is 18-30 VDC.

3.4 Encoder and brake control wiring

The encoder cable should be shielded twisted pair, with a length of ≤ 100 meters, and both ends of the shielding layer should be grounded;

Mechanical brake control must be driven by X21.9 relay output to drive external brake relays or micro contactors, and cannot directly drive brake coils;

When using BME brake rectifier, independent power supply is required, and the cable should be laid separately from the motor line and shielded.

EMC and UL compliant installation

4.1 Key points of EMC installation

To meet the Class B limit requirements of EN 61800-3:

NF type input filter must be installed at the input end and installed near the controller (distance ≤ 400mm);

It is recommended to shield the motor cable or use HD00X output reactor;

All shielding layers should be grounded at both ends, and the contact surface should be large and short;

The control signal line should be twisted pair and laid separately from the power cable.

4.2 UL Installation Requirements

Only applicable to equipment marked with UL logo;

Use 60/75 ℃ copper cables;

The maximum short-circuit current and rated value of the fuse at the installation point must comply with the specifications in the manual table (such as MKS51A series fuses not exceeding 30 A/600 V).

Startup and parameter settings

5.1 Initial setup steps

Connect PC and controller through RS-232 or RS-485 interface;

Set unique addresses (0-59) for each axis module to avoid address conflicts;

Install and configure the MD_SHELL software, select the corresponding communication interface and address.

5.2 Key parameter initialization

The "Start" function of MD_SHELL can automatically calculate the parameters of the speed controller, which requires inputting:

Motor model, rated voltage, rated speed;

Load inertia (converted to motor shaft);

Speed loop damping (recommended 1.0) and stiffness (recommended 0.8-1.2);

Braking characteristics, ramp time, etc.

5.3 Terminal Function Programming

In the factory default settings, X21.7 and X21.8 have limit switch inputs. If there is no external limit, it needs to be programmed for other functions or bridged to+24 V, otherwise it will trigger F27 fault.

Operation, status indication and fault handling

6.1 Status Display

Power module LED: green "ON" indicates ready, "24 V" indicates normal power supply, and red "TRIP" indicates fault;

Axis module/compact controller 7-segment digital display: displays operating status and fault codes (such as "F" flashing+digits).

6.2 Reset Method

Power off and restart;

Send a reset signal through binary input;

Automatic reset (P630 needs to be set);

Press the S1 button on the axis module (to be enabled in P634).

6.3 Common faults and solutions

Possible causes and suggestions for handling fault codes

F01 output overcurrent, short circuit or grounding fault inspection motor cable, insulation, replace module

F07 DC bus overvoltage check brake resistor connection and specifications, extend deceleration ramp

F08 speed monitoring out of tolerance inspection load, motor phase, encoder wiring

F14 encoder fault inspection encoder cable, shielding and wiring

F27 limit signal missing check wiring or reprogram terminals

Attention: After the fault is reset, the incremental encoder simulation will also reset, and the position information needs to be recalibrated.

Overview of Technical Data

Environmental conditions: operating temperature 0-45 ℃ (with a 3% derating per K when above 45 ℃), storage temperature -25-+70 ℃, protection level IP20;

Power input: 3 × 380-500 VAC ± 10%, 50/60 Hz;

Communication interface: RS-485 supports networking up to 32 devices, with a maximum cable length of 200 meters;

Module power consumption and size: Please refer to the table in Chapter 8 of the manual for details. It is necessary to select a heat sink and filter based on the specific model.

Maintenance and Service Suggestions

Regularly clean the surface of the radiator to ensure smooth ventilation;

When stored for a long time, power on for at least 5 minutes every two years to maintain capacitor performance;

If the fault cannot be resolved, please contact the SEW electronic service department and provide the code, fault symptoms, and relevant contextual information on the device service label.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands