SHINKAWA VM-5 Series Monitor

SHINKAWA VM-5 Series API 670 Standard Turbine Monitoring System

In the field of modern industrial automation, especially for the protection and monitoring of key rotating machinery such as steam turbines, gas turbines, and large compressors, the reliability, accuracy, and flexibility of monitoring systems are crucial. The VM-5 Series monitor launched by Shinkawa, as a specialized mechanical protection system that fully complies with the American Petroleum Institute API 670 standard, has become the preferred monitoring solution for turbine management systems (TSI) and large power generation machinery due to its modular design, highly flexible configuration, and comprehensive fault detection capabilities.

This article will delve into the system architecture, core monitoring unit technology, redundancy design, and application advantages of the VM-5 series in complex industrial scenarios.

1. Modular architecture and flexible configuration

The biggest feature of the VM-5 series is its excellent modular design, which can be flexibly combined according to different system scales and on-site environments. The system mainly consists of four core units: monitoring unit, relay unit, power unit, and instrument rack.

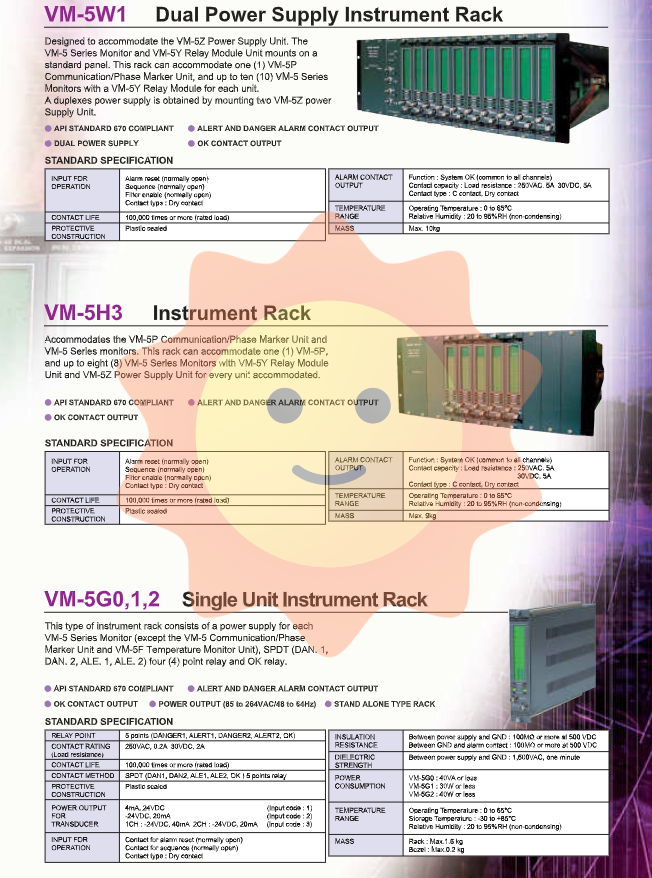

Instrument rack type: The system provides two rack models.

VM-5H3 (8-slot rack): can install up to 8 monitoring units and related modules.

VM-5W1 (10 slot rack): can install up to 10 monitoring units.

VM-5G (Monogram): A compact single rack design with built-in power supply, suitable for small machinery or independent systems with limited space.

Dual power supply and hot backup redundancy: In order to ensure the continuous operation of the system during power supply fluctuations or instantaneous power outages in industrial sites, VM-5 provides a unique power redundancy solution.

VM-5W1 Dual Power Instrument Rack: It can accommodate two VM-52Z power units, and when the main power fails, the backup power seamlessly switches in.

VM-5Z0 power backup module: This is a high reliability technology of the VM-5 series. When the rack detects an instantaneous power outage (such as lightning strike or grid switch), the module can immediately provide DC power backup to the system, with a support time of up to 0.2 seconds. This greatly avoids control logic misoperation or data loss caused by voltage fluctuations.

This modular architecture not only facilitates installation and maintenance, but also allows users to freely expand the system capacity based on the number of monitoring points (such as only monitoring vibration or simultaneously monitoring temperature and speed).

2. Detailed explanation of core monitoring unit technology

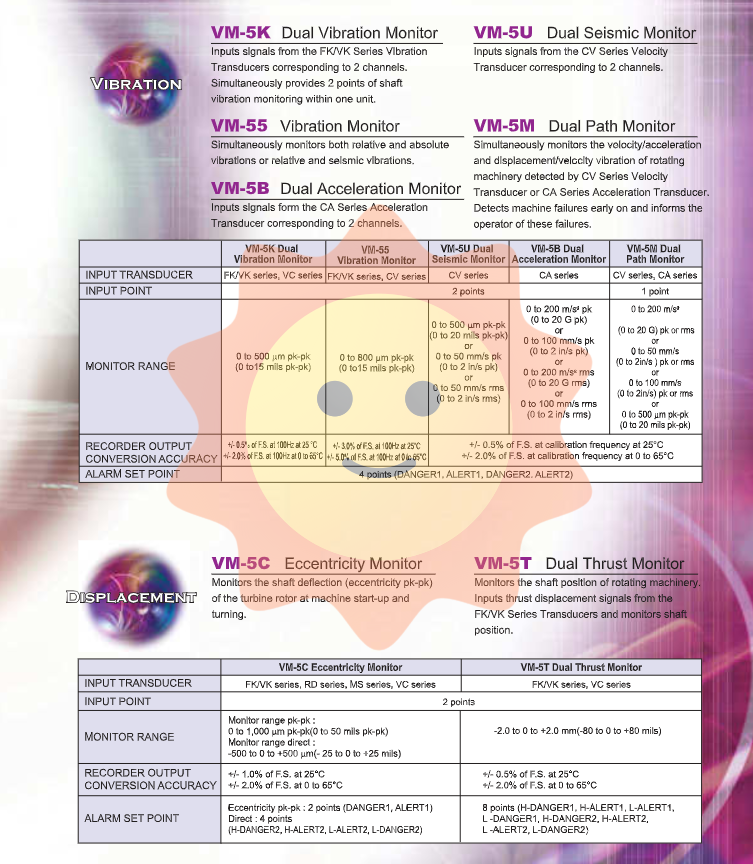

The VM-5 series offers 18 different monitoring units, covering full dimensional detection from vibration, displacement to speed and temperature. These units use high reliability Shinkawa transmitters as input front-end, ensuring the accuracy of data source.

Vibration monitoring: velocity, acceleration, and displacement

VM-5K Dual Channel Vibration Monitor: Supports FK series (speed sensor) or VC/CA series (acceleration sensor) inputs. It can simultaneously monitor the shaft vibration of two channels, providing universal DANGER and ALERT alarm settings.

VM-5B Dual Channel Acceleration/Velocity Monitor: Specially designed to monitor velocity, acceleration, and displacement (vibration velocity) simultaneously through CA series acceleration sensor input. It can automatically calculate the vibration values of the entire frequency band based on the sensor type, achieving accurate capture of early faults in rotating machinery such as bearing wear and imbalance.

VM-5M Dual Channel Path Monitor: With extremely high flexibility, it can simultaneously monitor relative and absolute vibrations, or relative and seismic vibrations, making it suitable for complex machinery that requires comparative analysis of multiple signals.

Mechanical position and differential expansion monitoring: compensation and calculation

VM-5C dual channel eccentricity monitor: mainly used to monitor the shaft deflection (eccentricity) of the rotor during start-up and operation. Detecting the offset of the rotor relative to the bearing center through the VK/RD/MS series displacement sensor is crucial for avoiding dynamic and static friction and shaft damage.

VM-5T dual channel thrust monitor: monitors the axial position (axial displacement) of the rotor. It receives displacement signals at the thrust bearing, which can not only monitor the wear of the thrust surface, but also make comprehensive judgments based on differential expansion signals.

VM-5D Dual Channel Differential Expansion Monitor: This is one of the most critical parts of turbine protection, used to monitor the differential expansion between the rotor and the casing caused by thermal expansion. In order to eliminate measurement errors, VM-5D adopts a unique complementary input technology. For example, sensors on the casing are usually located far away from the thrust bearing, and the VM-5D receives this signal and calculates the true differential expansion value, thereby eliminating measurement deviations caused by rotor uplift (such as changes in oil film thickness).

VM-5E Dual Channel Chassis Differential Expansion Monitor: This is the advanced version of VM-5D. It receives differential expansion signals from the LS series LVDT (linear variable differential transformer) and combines them with the output of VM-5D to perform compensation calculations, thereby obtaining the final accurate differential expansion value. This configuration greatly improves measurement accuracy.

VM-5J casing expansion/complementary differential expansion monitor: receives signals from two sensors, adopts complementary arrangement, and can measure a differential expansion range of twice the sensor range.

VM-5N Slope Differential Expansion Monitor: specifically designed to monitor thermal expansion at the rotor slope position to prevent dynamic and static friction.

Rotation and speed monitoring

VM-5S dual channel tachometer: monitors rotor speed, supports forward and reverse detection, and provides zero speed detection. This is crucial for preventing reverse start-up and monitoring the shutdown process.

VM-5Q Reverse Rotation Monitor: specifically designed to detect reverse operations and indicate peak reverse speeds that have occurred.

VM-5R tachometer: While monitoring speed, it can also monitor the acceleration of the rotor and independently set the alarm comparison values for speed and acceleration.

VM-5A valve position monitor: receives valve position signals from LS series LVDT and displays them digitally, suitable for hydraulic speed control systems.

Temperature and special process monitoring

VM-5F dual channel temperature monitor: designed to monitor the temperature of rotating machinery components. It supports grounded or ungrounded thermocouples and 3-wire or 4-wire RTD inputs, with a measurement range of up to 1000 ° C (1832 ° F), fully meeting the monitoring needs of steam turbines and heavy oil machinery.

VM-51 Piston Rod Drop Monitor: This is a specialized monitoring unit for reciprocating compressors. It detects the amount of piston rod drop by measuring the gap between the sensor and the target of the piston rod, usually synchronized with the phase marker signal, and is used to estimate the wear of the piston ring.

VM-52 Bottom Hold Monitor: monitors the gap between the sensor surface and the target surface (bottom gap), used to monitor the bottom hold status of the compressor.

3. Highly integrated relay and interface system

The VM-5 series is not only a data collector, but also an executor of control logic. Through the relay module and interface unit in the backend, it can convert complex analog signals into standard switch or analog outputs, which can be directly connected to DCS or PLC systems.

VM-5Y series relay module unit:

Standard Type (VM-5Y1-3): Provides standard contact outputs (DANGER, ALERT, OK). The input power is 4mA/24VDC or 40mA/24VDC, suitable for general control circuits.

Connector type (VM-5Y4, 5Y5, 5Y6): This is the characteristic feature of this series. In addition to standard contact output, it also provides recorder output through D-Sub interface. Among them, VM-5Y6 also provides buffered output. These outputs are 0-10VDC (or 4-20mA), corresponding to the percentage of monitoring range (0% FS), which can directly drive the chart recorder for historical trend analysis.

VM-5Y7: Designed specifically to complement the VM-5F temperature monitor, providing relay logic for temperature alarms.

VM-5X interface unit and VM-5P labeling unit:

VM-5X: As a signal distribution hub, it collects signals from all monitoring units in the rack and converts them into analog signals (0-5VDC or 4-20mA) or contact signals for output. It supports four output points for each input point (corresponding to OK, ALERT1, ALERT2, DANGER, etc.).

VM-5P: Monitor phase sequence signals (such as rotation direction or phase failure), and provide system normal (OK) contact signals and built-in power supply voltage failure detection function.

VM-53 dual communication unit:

This module is the key to implementing digital management in the VM-5 system. It has two independent serial ports, collects all data inside the rack using Modbus protocol (a registered trademark of Modicon), and sends it to the upper computer (such as the host PC or DCS). More importantly, VM-553 supports daisy chain connections and can collect data from two or more racks, greatly expanding the number of monitored nodes in the system.

4. Data analysis and diagnostic software

In order to fully exploit the massive data collected by the VM-5 hardware, Shinkawa provided the matching inSYS RV-200 vibration analysis and diagnosis system. This software can be connected to the monitoring system through the VM-53 unit to perform detailed fault diagnosis on rotating machinery, such as bearing fault frequency analysis, resonance recognition, etc. It is not only a monitoring tool, but also an expert system for predictive maintenance.

5. Safety compliance and environmental adaptability

The VM-5 series strictly adheres to the highest international standards from the beginning of its design:

API 670: Fully complies with the American Petroleum Institute's monitoring standards for auxiliary machinery and is a legal configuration for TSI systems.

IACS certification: Obtained international classification society certification, suitable for marine platforms and ship propulsion turbines.

IECEx/ATEX: Provides intrinsically safe explosion-proof models that can operate safely in hazardous areas (places with flammable gases or dust).

CE mark: Complies with the European Machinery Directive and related EMC/LVD directives.

In addition, the system adopts lead-free soldering technology, which complies with the RoHS directive and reflects a commitment to environmental protection.

Model Supplement

MP-2T

MP-2S

MP-2P4

MP-2P1

MP-2W2

VM-5K SST-2194-001-P001G

VM-5Y1-02/GEM 1594-005-P001G

VM-5H3

VM-5P3

VM-5Z4

VM-5C SST-2194-001-P001G

VM-5G0-2

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands