Honeywell Safety Manager(Release 162)

Honeywell Safety Manager(Release 162)

This manual is the authoritative hardware guide for Honeywell Safety Manager Safety Instrumented Systems (SIS), applicable to industrial process safety control scenarios such as chemical, petroleum, energy, etc. The core objective is to guide engineers in completing system installation, configuration, maintenance, and troubleshooting, ensuring that the system meets SIL 1-3 safety integrity requirements and complies with international safety standards such as IEC 61508 and IEC 61511.

Basic information and security compliance in the manual

(1) Manual positioning and target audience

Core positioning: Covering the technical specifications, installation process, and maintenance methods of the entire hardware components of Safety Manager, it is the core reference for system design, debugging, and operation;

Target audience: Hardware engineers, on-site operation and maintenance personnel, system integrators, who need to have a basic understanding of PLC, industrial safety standards (such as IEC 61508), and Windows system operation ability.

(2) Safety Compliance and Certification

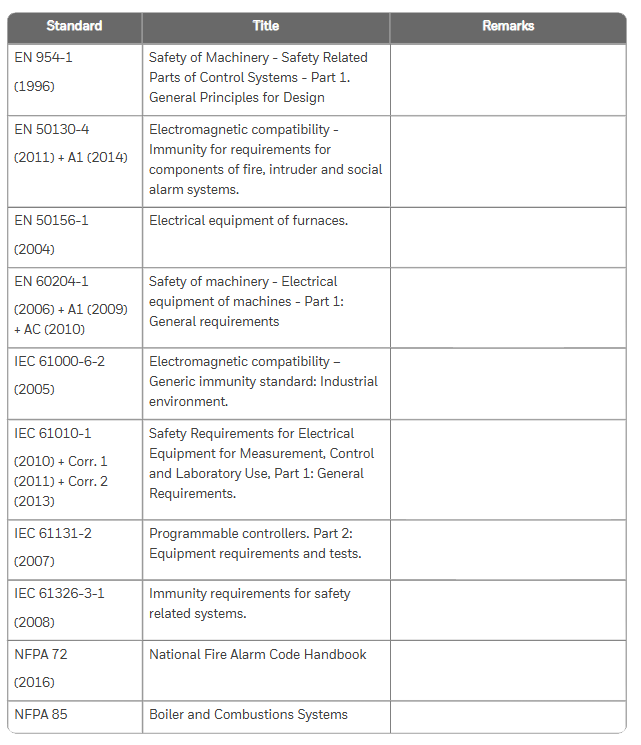

Safety standards: comply with IEC 61508 (functional safety), IEC 61511 (process industry SIS), ISO 13849-1 (mechanical safety), UL 508 (industrial control equipment), etc;

Hazardous Area Certification: ATEX, IECEx (Ex nA IIC T4, applicable to Zone 2 areas), FM 3611 (Class I/II Division 2 hazardous areas, such as chemical explosive environments);

Environmental Protection and Electromagnetic Compatibility: Compliant with RoHS Directive (Halogen Free Design) and EN 61000-6-2 (Electromagnetic Immunity in Industrial Environments), ensuring stable operation in complex industrial environments.

System hardware composition and core modules

The Safety Manager hardware system adopts a three-layer architecture of "cabinet chassis module", with core components including cabinet, controller chassis, IO chassis, power module, control processor module, input/output module, etc. The functions and technical parameters of each component are as follows:

(1) Cabinet: Physical carrier of the system

Standard configuration: Based on Rittal TS 8 series cabinets, default protection level IP20, optional IP54 upgrade; Including cooling fans (such as FANWR-24R, 24V DC with status feedback), thermostats (monitoring cabinet temperature to avoid module overheating), grounding bars (ensuring equipment grounding resistance ≤ 4 Ω), lighting fixtures (easy to maintain);

Key parameters: dimensions (such as 80 × 60 × 200cm, 80 × 80 × 200cm), weight (full load ≤ 550kg), operating temperature (-5~70 ℃, remote cabinet -40~70 ℃).

(2) Chassis: Module Installation and Signal Transmission Core

Divided into controller chassis (CPCHAS series) and IO chassis (IOCHAS series), supporting redundant/non redundant configurations to meet different safety level requirements:

Chassis type, model example, core functions, key specifications

Controller chassis CPCHAS-0001 is equipped with a control processor module to achieve system logic operations. It supports 1-2 Control processors, with a height of 4HE and a standard size of 19 inches

Non redundant IO chassis IOCHAS-0001S is equipped with non redundant IO modules, supporting 18 IO modules connected to on-site sensors/actuators, powered by 5V-R (redundant 5V)

Redundant IO chassis IOCHAS-0001R is equipped with redundant IO modules to improve system fault tolerance. It supports 9 pairs of redundant IO modules and a dual IO bus design

(3) Power Supplies: System Stable Power Supply Guarantee

Provide multiple types of power modules, supporting AC-DC conversion and redundant power supply, to meet different voltage requirements (24V/48V/60V/110V/120V DC). The core models and parameters are as follows:

Power supply model, output specifications, core characteristics, applicable scenarios

PSUNI2424 24V DC/24A, 600W dual overvoltage protection (SIL3 compatible), core controller power supply for operating temperature of -40~70 ℃

PSU-UNI2450U 25-28V DC/43-48A UL 508 certification, 100ms power-off hold, supports parallel expansion and high load IO module cluster power supply

FEEDER-24R 24V DC/63A redundant design, with status feedback relay, overcurrent protection redundant system main power feeder

(4) Control Processor Modules: The System's Brain

QPP-0002 (Quad Processor Pack): Core computing module, dual processors running synchronously, with Flash/RAM storage (battery backup, BKM-0001 module provides battery), supports Watchdog function (monitoring program execution time, memory errors), meets SIL3 requirements;

USI-0002 (Universal Safety Interface): Communication module, providing 2 channels of 10/100M Ethernet and 2 channels of universal serial communication (RS232/485), supporting interconnection with systems such as Expert PKS, with hardware firewall function;

BKM-0001 (Battery and Key Switch Module): A battery and key switch module that includes 2 lithium batteries (backup RAM data, approximately 3 months of battery life), a reset key (clear fault logs), and a forced enable key (allow IO signal forcing).

(5) I/O Modules: Field Signal Interaction

Input module: supports digital/analog signal acquisition, with fault self detection function, core models such as SDI-1624 (24V DC 16 channel digital input), SAI-1620m (16 channel analog input, 0-4V), SDI-1608 (16 channel digital input with ground fault monitoring);

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com