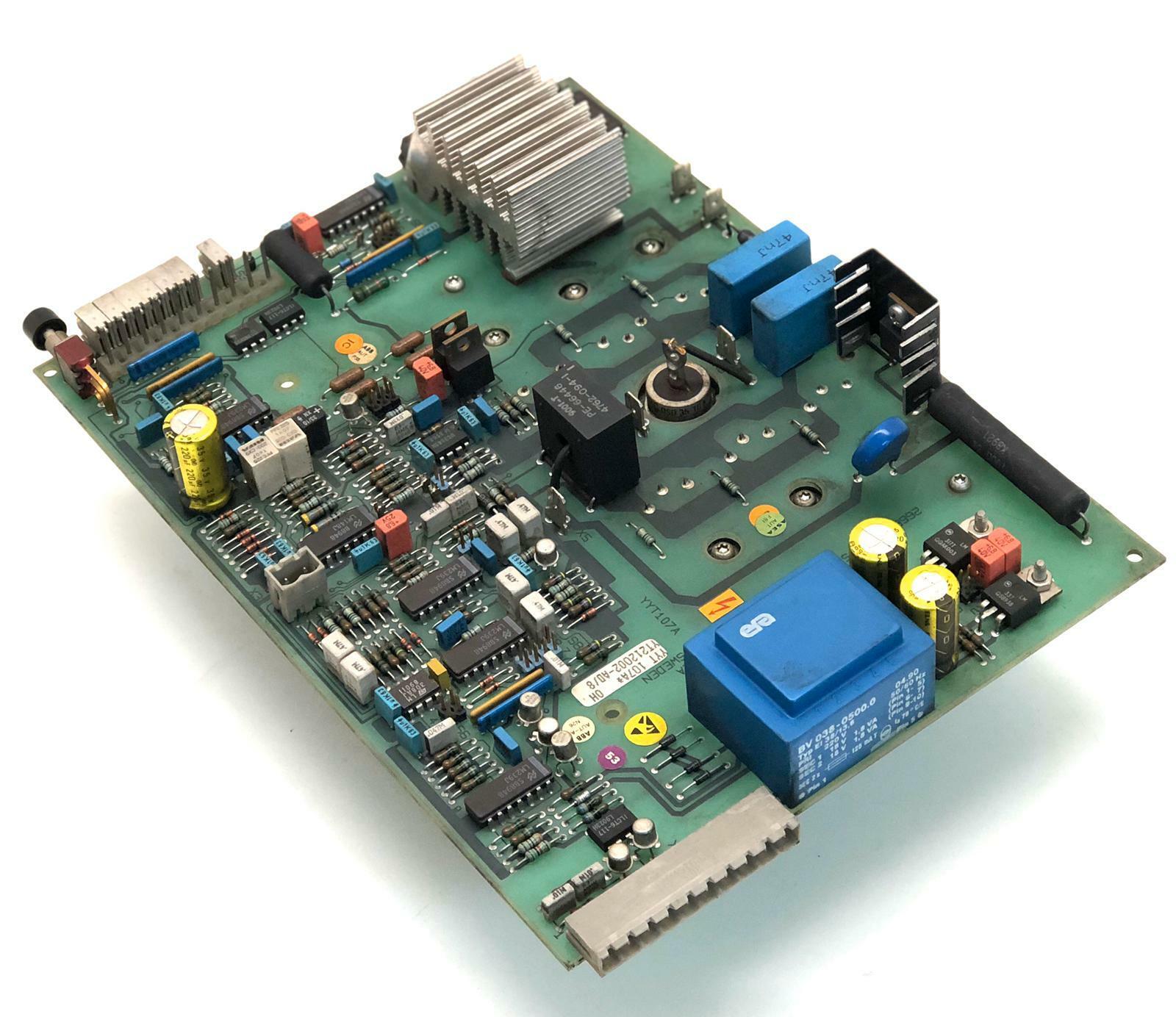

ABB YYT107A YT212002AD PLC module

(2) Powerful flexibility and scalability

Rich I/O point configuration and support for multiple programming languages enable users to flexibly customize control functions according to different industrial control needs. The modular design concept facilitates system expansion, allowing for easy increase in I/O points or expansion of other functions by adding expansion modules, meeting the needs of industrial production scale expansion and process upgrades.

(3) Efficient and user-friendly

The friendly programming interface and intuitive operation method lower the threshold for use, allowing even beginners to quickly get started. At the same time, comprehensive documentation and technical support facilitate users in program development, debugging, and maintenance, improving work efficiency.

(4) Wide compatibility

Supporting multiple industrial communication protocols and interfaces, it can seamlessly integrate with different brands and types of industrial automation equipment, facilitating the construction of diverse industrial automation control systems and meeting the application needs of different industries.

Precautions

(1) Installation environment requirements

When installing, a dry, well ventilated, and suitable temperature environment should be selected to avoid installation in places with high temperature, humidity, corrosive gases, or strong electromagnetic interference. If it is impossible to avoid harsh environments, effective protective measures should be taken, such as installing heat dissipation devices, electromagnetic shielding equipment, etc., to ensure the normal operation of the module.

(2) Wiring standard operation

Strictly follow the wiring diagram in the product manual to connect the power and signal lines, ensuring correct wiring and accurate polarity. Different types of signals (such as analog, digital, and power lines) should be wired separately to avoid signal interference. After the wiring is completed, carefully check whether the wiring terminals are secure to prevent loose connections that may cause poor contact or short circuits.

(3) Programming and Maintenance

Before programming and parameter setting, it is necessary to fully understand the industrial control requirements and the functional characteristics of the module, to ensure that the control program logic written is correct and the parameter settings are reasonable. Regularly maintain the module, including cleaning surface dust, checking electrical connections, backing up program data, etc., to ensure that the module is always in good operating condition.

Application scenarios

(1) Manufacturing automation production line

In automated production lines in industries such as automobile manufacturing and electronic equipment manufacturing, it is used to control the movement of robotic arms, the operation of conveyor belts, and the start stop of equipment, achieving automation and intelligence in the production process. By precise logical control and data processing, the processing accuracy and production efficiency of the product are ensured, and labor costs are reduced.

(2) Power system monitoring and control

In power plants, substations and other electrical facilities, it is used to monitor and control the operating status of electrical equipment, such as the speed, voltage, current of generators, and the opening and closing operation of circuit breakers. Realize automated monitoring and protection of the power system, and improve the reliability and stability of power supply.

(3) Automation of chemical production processes

In chemical production, precise control of key process parameters such as temperature, pressure, and flow rate of reaction vessels is necessary to ensure that chemical reactions occur under safe and stable conditions. At the same time, controlling the material conveying, mixing, separation and other links in the chemical production process can improve production efficiency, reduce production costs and safety risks.

(4) Intelligent Buildings and Building Automation

In intelligent building systems, it is used to control equipment such as elevator operation, lighting systems, air conditioning systems, security systems, etc. Realize automated management and energy-saving control of building equipment, providing users with a comfortable, convenient, and safe environment.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands